Method for controlling bare concrete wall column reinforcement protective cover

A steel protective layer and fair-faced concrete technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconsistent surface color of newly poured concrete, poor concrete durability, and easy formation of air bubbles on the building surface, so as to improve the appearance. Quality, uniform bubbles, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

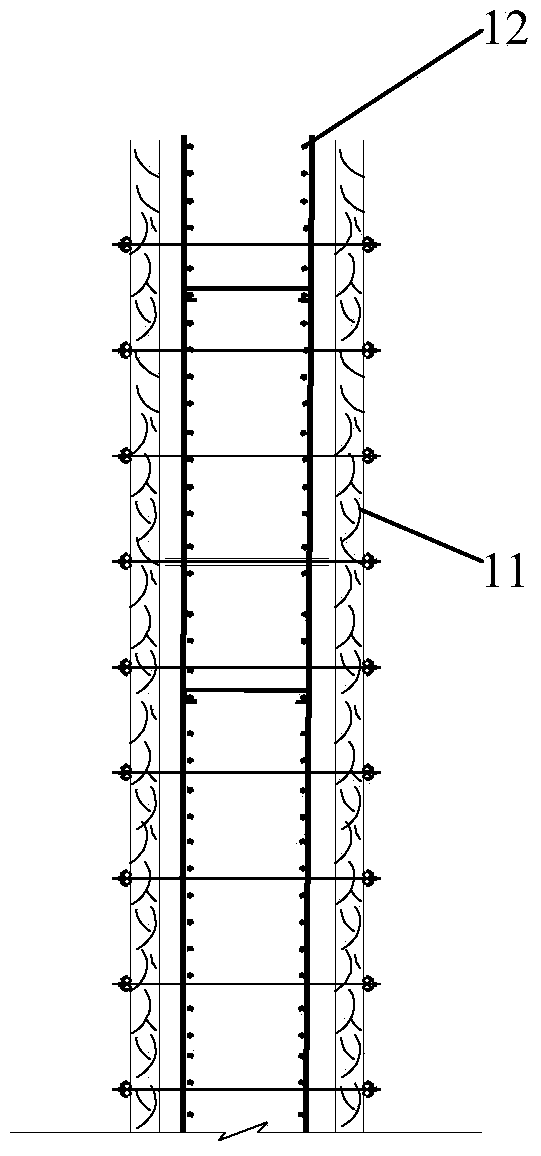

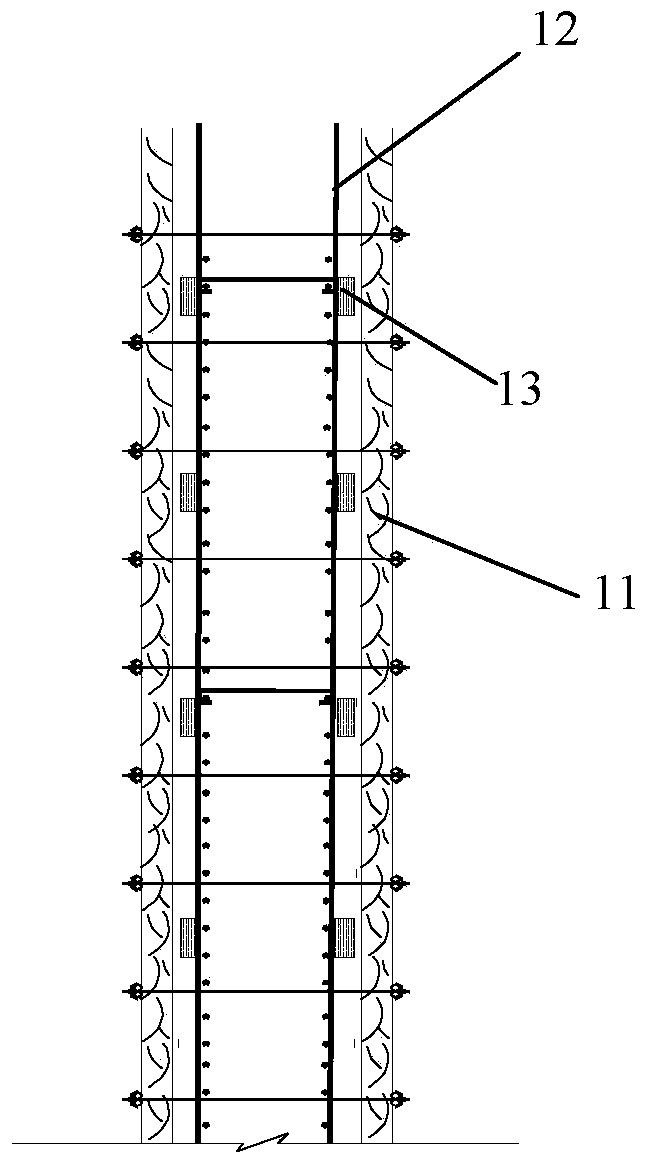

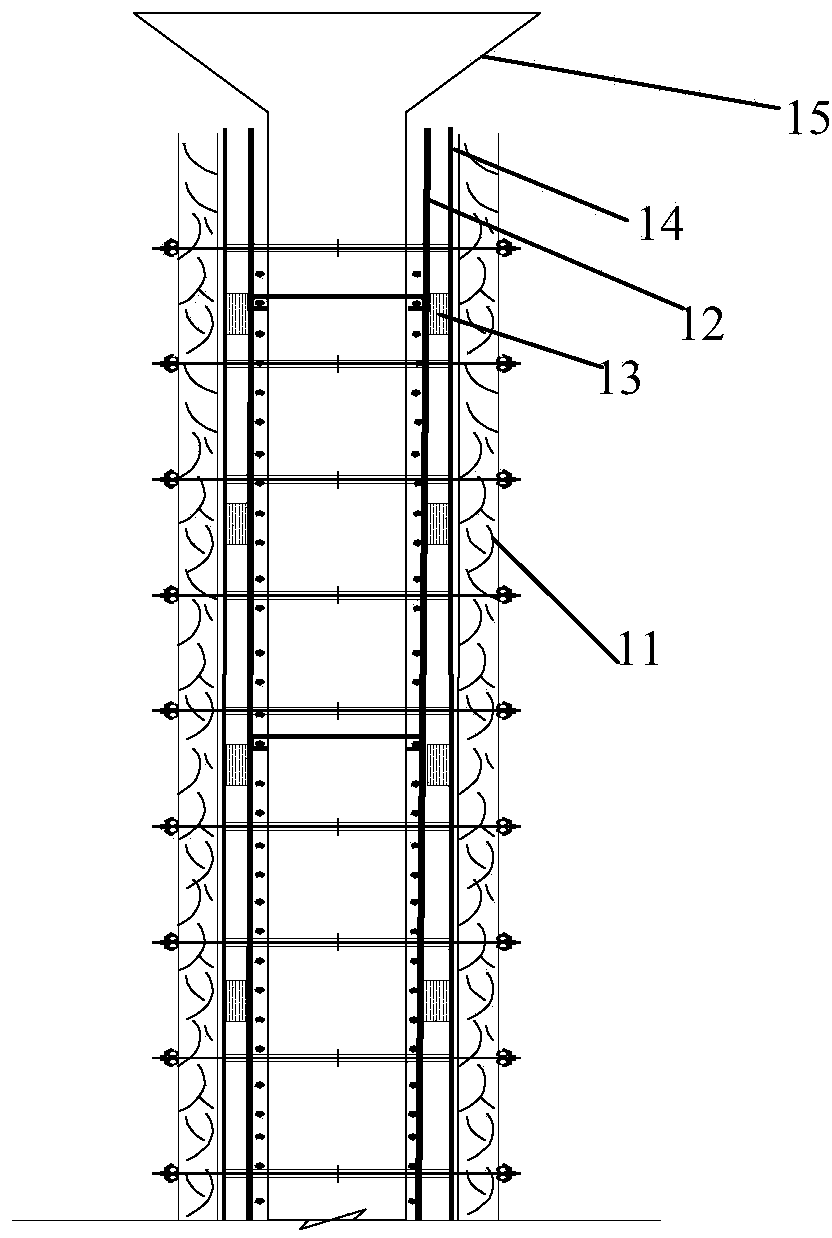

[0015] The method for controlling the steel bar protection layer of fair-faced concrete wall columns proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0016] The core idea of the present invention is that the method for controlling the steel bar protective layer of clear-water concrete wall columns can improve the appearance quality of clear-water concrete, make the surface color of clear-water concrete consistent without obvious color difference, without obvious cracks, uniform and small air bubbles, and after demoulding The surface is smooth and smooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com