Method for processing stress-fringe-order numerical values of photoelastic model

An elastic model and processing method technology, applied in the field of photoelasticity testing, can solve problems such as the inability to control the test accuracy effectively, the processing method accuracy is low, the stress fringe level is small, etc., achieving low processing cost, increased fringe level, The effect of precise and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered.

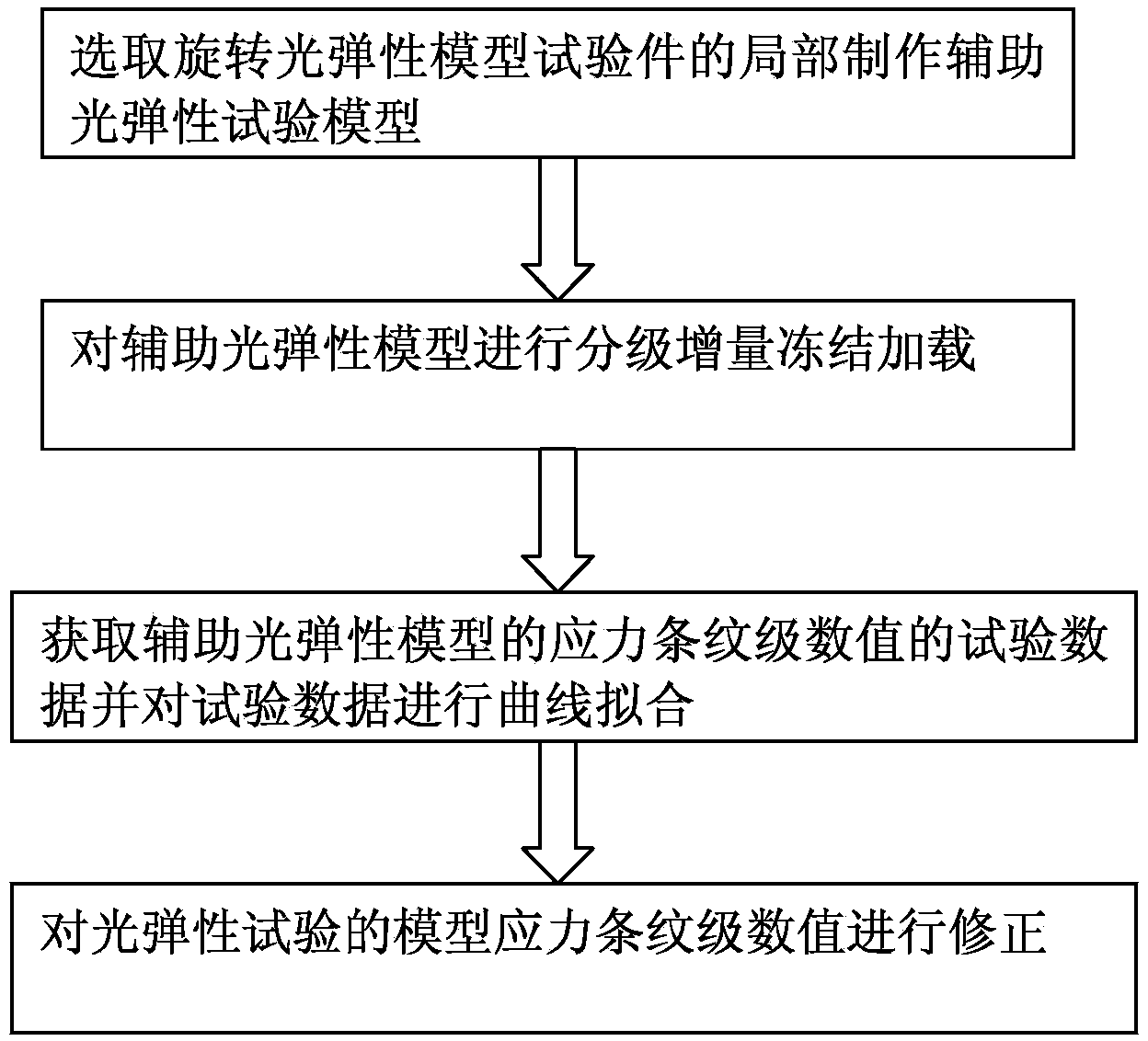

[0028] figure 1 It is a schematic flow chart of the processing method of the stress fringe series of the photoelastic model of the preferred embodiment of the present invention, as figure 1 As shown, the processing method of the stress fringe level value of the photoelastic model of the present embodiment includes the following steps: a, select a part of the rotating photoelastic model test piece and adopt the same manufacturing method as the photoelastic model to make an auxiliary photoelastic model; b . Convert the rotational centrifugal force acting on the auxiliary photoelastic model into a tensile force, and perform stepwise incremental freeze loading on the auxiliary photoelastic model; c. Experiments to obtain the stress stripe level values of the auxiliary pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com