Drop test table

A technology of drop test and test bench, applied in the direction of impact test, machine/structural component test, measuring device, etc., can solve the problems of high price, poor stability and repeatability, difficult to achieve, etc., and achieve human influence factors Low, good stability and repeatability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

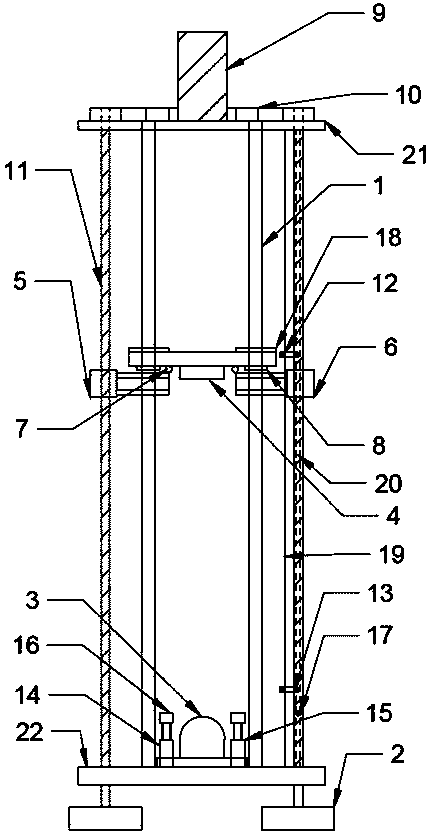

[0012] specific implementation

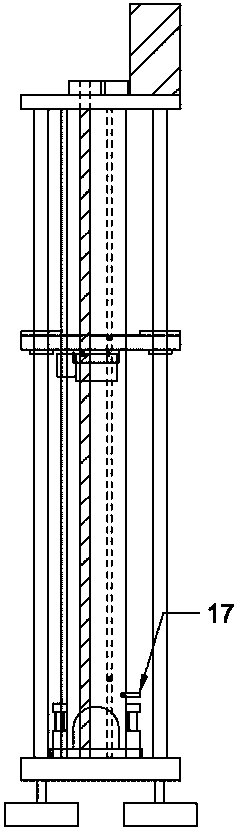

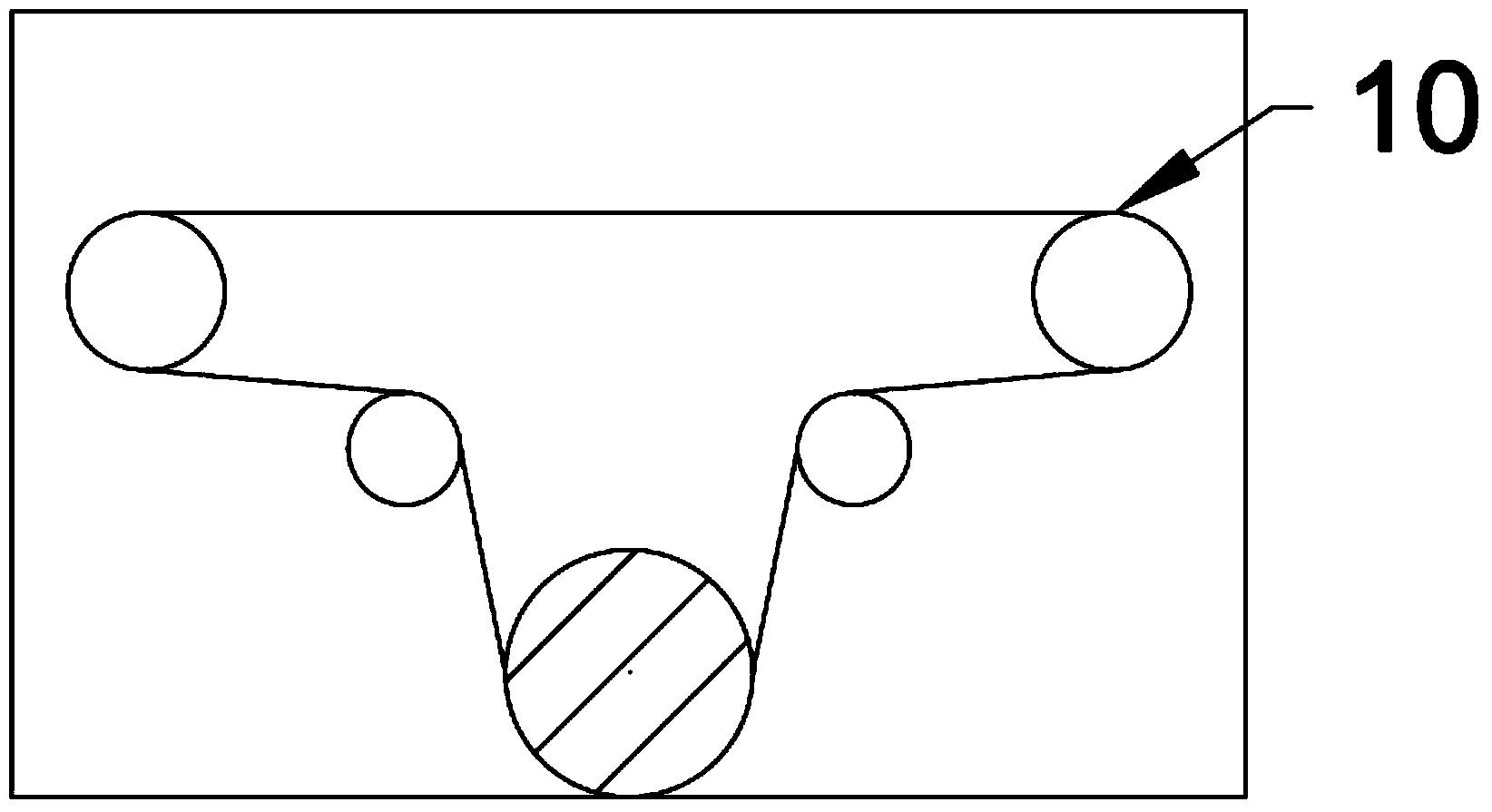

[0013] The support system includes four guide rails 1, which support the entire drop platform structure by fixedly connecting the upper and lower tables, and four shock absorbing pads 2 are fixed on the lower table and evenly distributed at the four corners of the lower table to buffer the entire drop platform. The support system includes a rigid base 3 fixed on the lower table, and a collision plane 4 fixed below the falling table 18. Both of them are made of rigid materials, which can generate a large impact acceleration during the impact of the drop; the drop lifting system includes a motor 9, The pulley II10 is located above the falling table 21 and is connected by a conveyor belt. The ball screw 11 is located on both sides of the falling table 20 and is connected with the II pulley 10. The motor 9 can drive the pulley II10 forward and reverse through the frequency converter. Rotate to drive ball screw 11 to work forward and reverse; Cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com