Splash-proof device for atomization mechanism research and test platform

A technology for researching experiments and platforms. It is used in measuring devices, testing of mechanical components, and testing of machine/structural components. It can solve problems such as splashing water, affecting the accuracy of atomization measurement, and affecting the laboratory environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

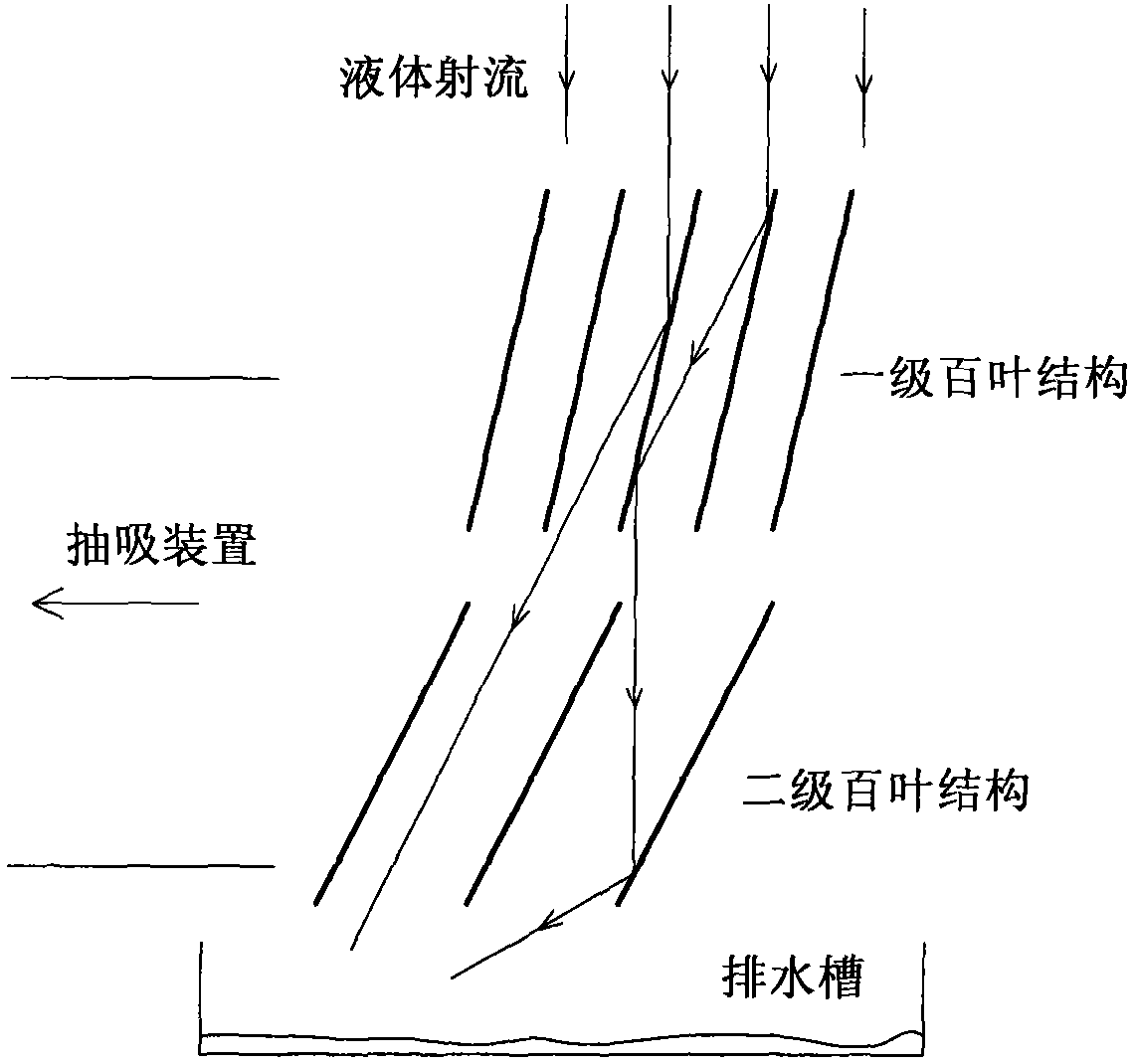

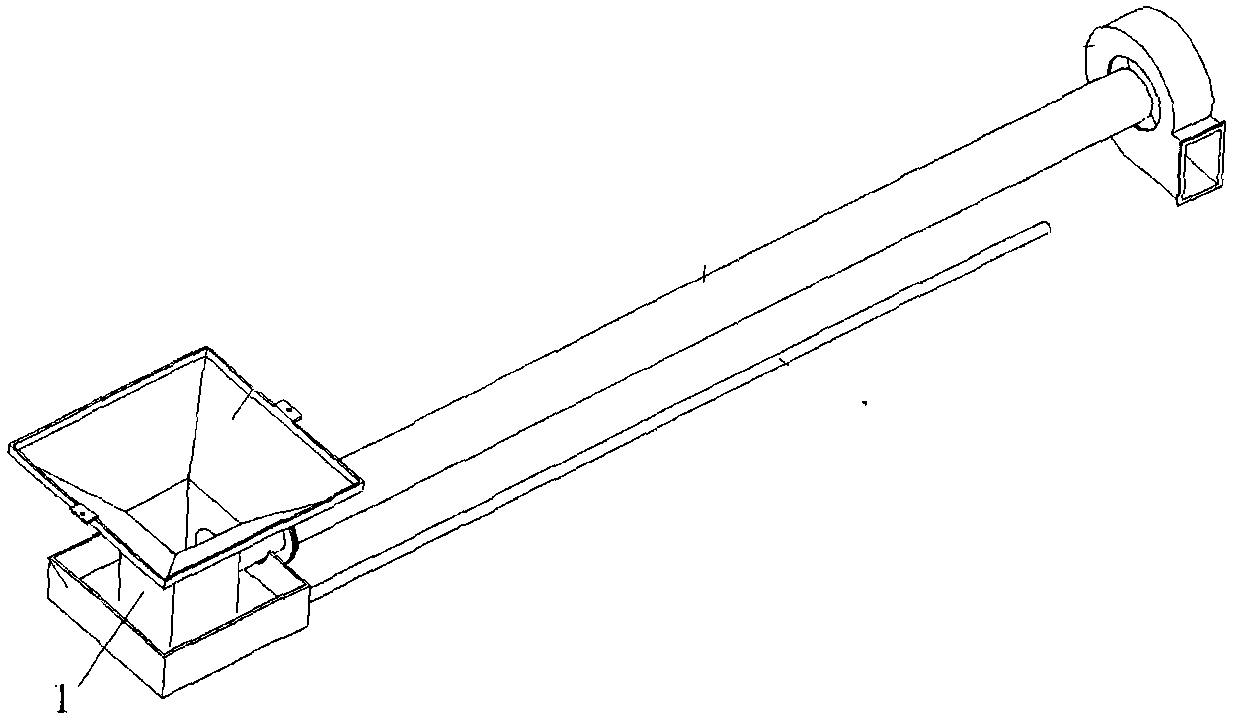

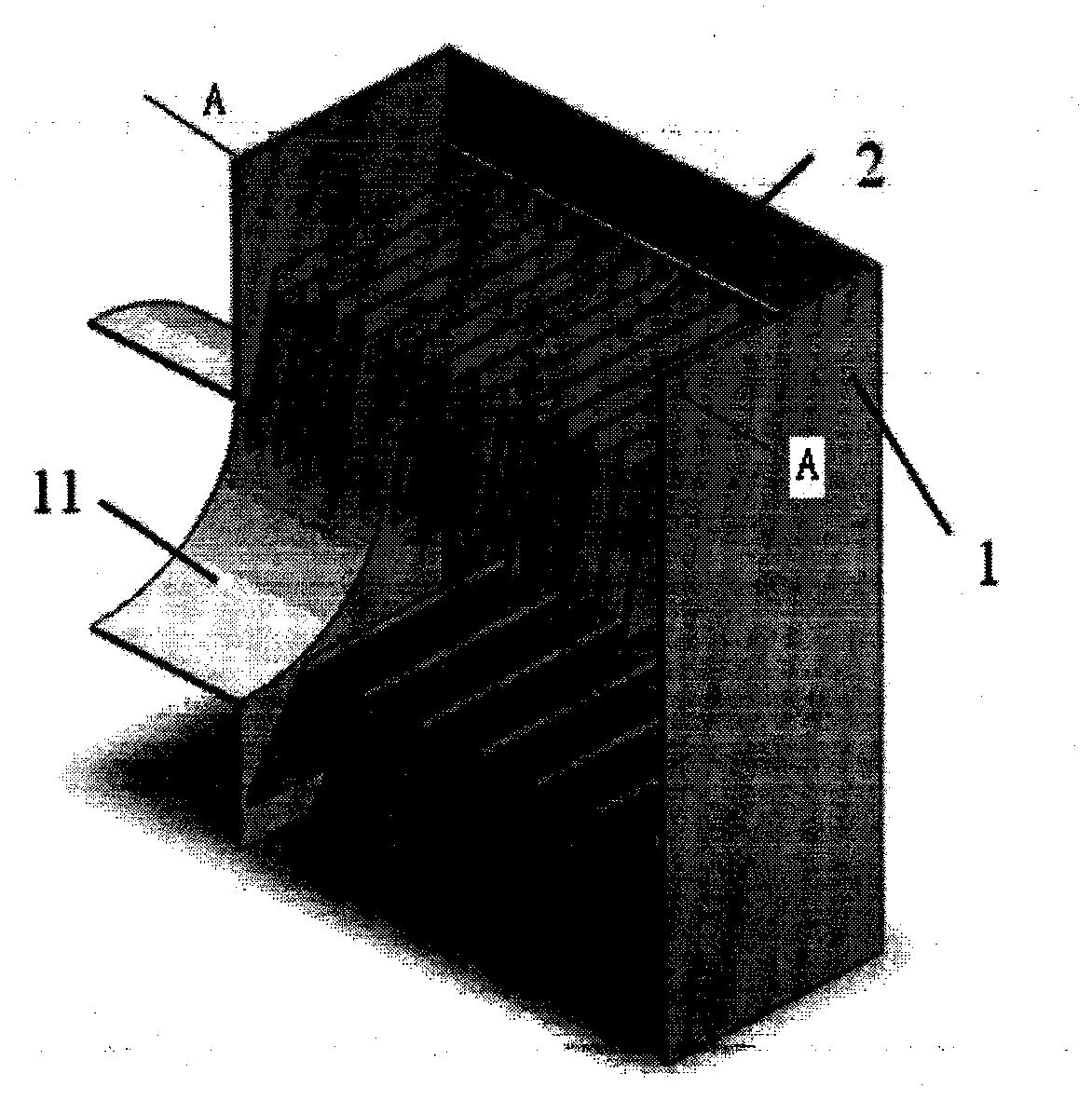

[0027] The anti-splash device of the present invention is as Figure 4 As shown, it includes a side wall 21 , a primary louver structure 22 and a secondary louver structure 23 .

[0028] The side wall 21 is used to fix and support the two-stage louver structure, and a rectangular groove is opened at the bottom of the side wall for drainage.

[0029] The primary louver structure 22 is composed of several parallel blades 221. The blades 221 are placed between the two side walls 21 with an inclination angle γ. . The A-A cross-sectional shape of the blade 221 is a parallelogram, wherein the acute angle α is equal to the inclination angle γ of the blade 221 , so that one side of the quadrilateral in section after the blade 221 is fixedly connected to the side wall 21 remains vertical. Adjacent blades 221 lie in the same vertical plane from head to tail, such as BC and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com