Flaw detection and simulated test device and flaw detection and simulated test system of steel rail

A test device and rail technology, applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve the problems of lack of verification methods in the detection system, easy to be restricted by the environment, and high test costs. The construction cost is low and the effect of getting rid of the constraints of the objective environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

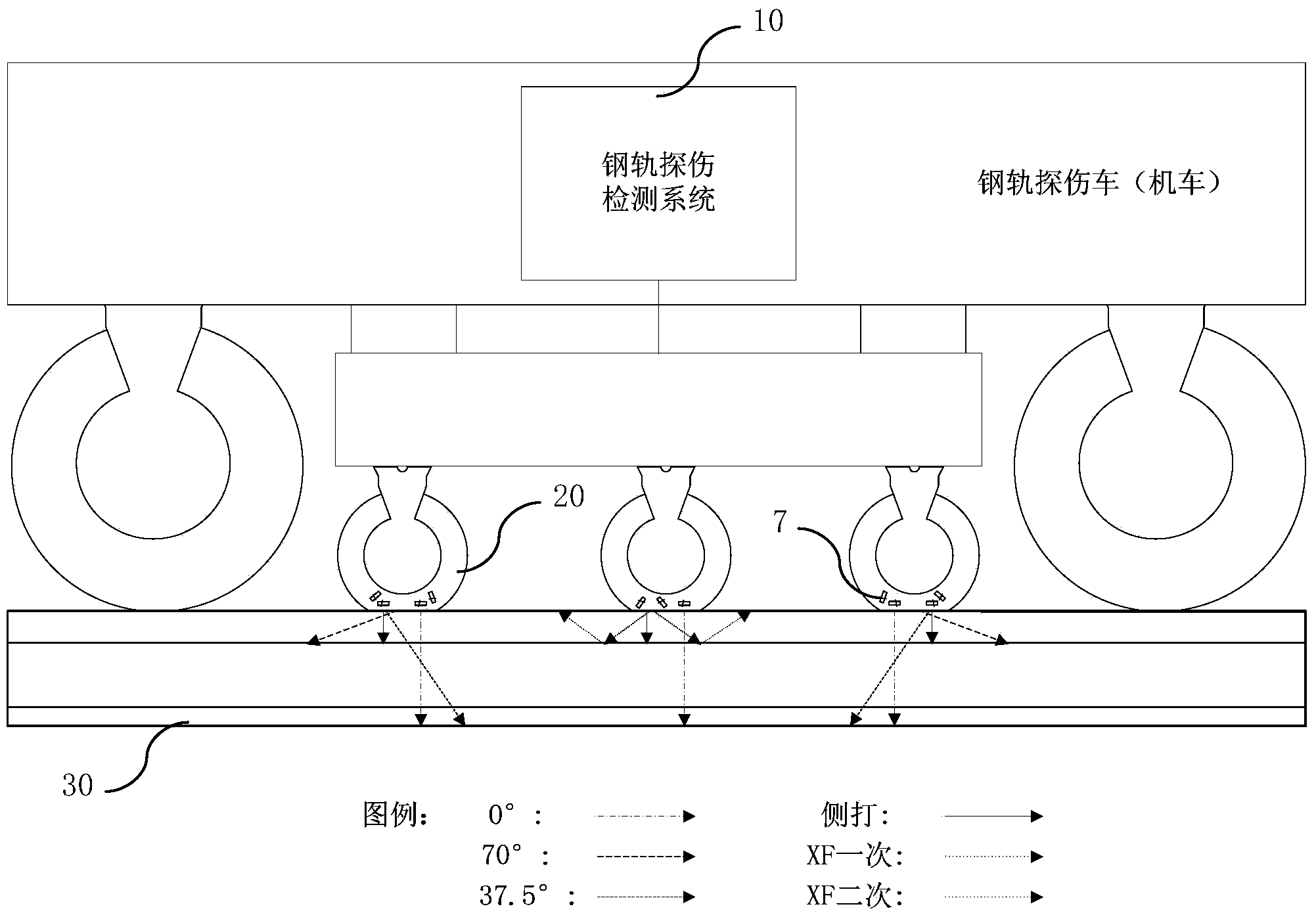

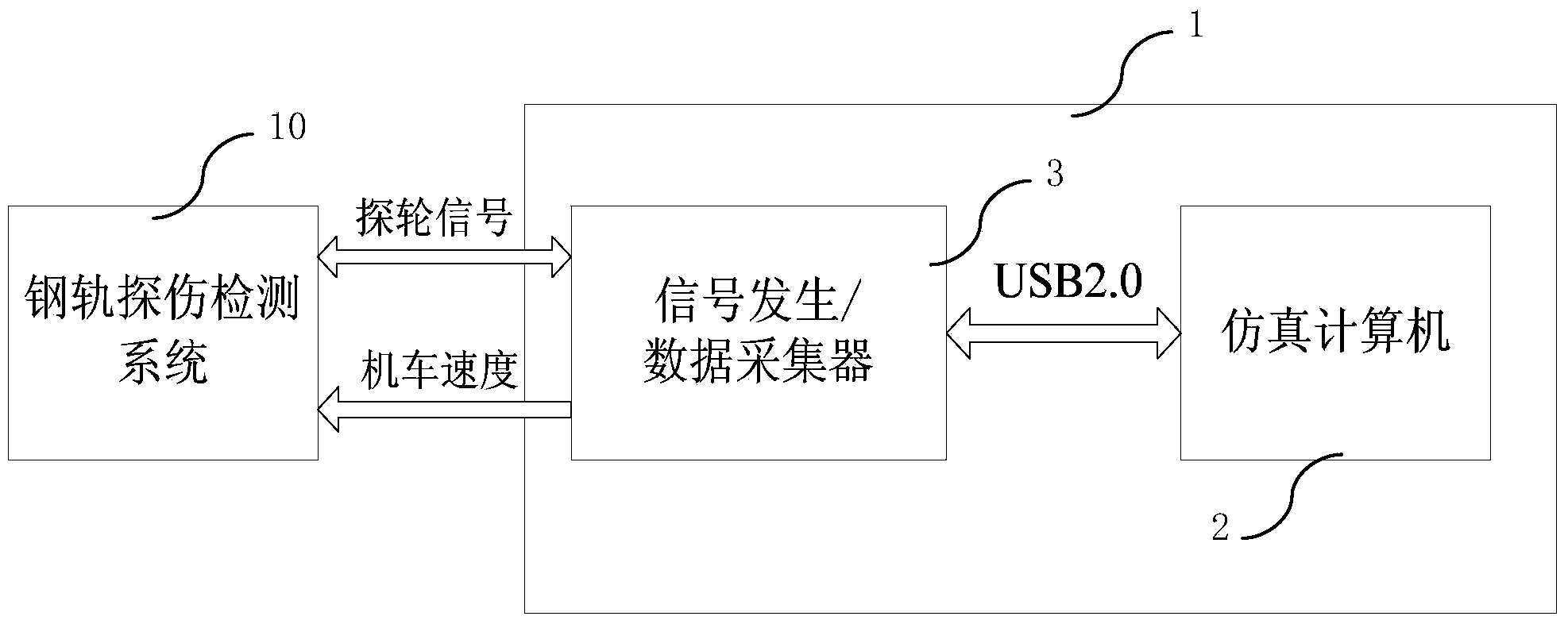

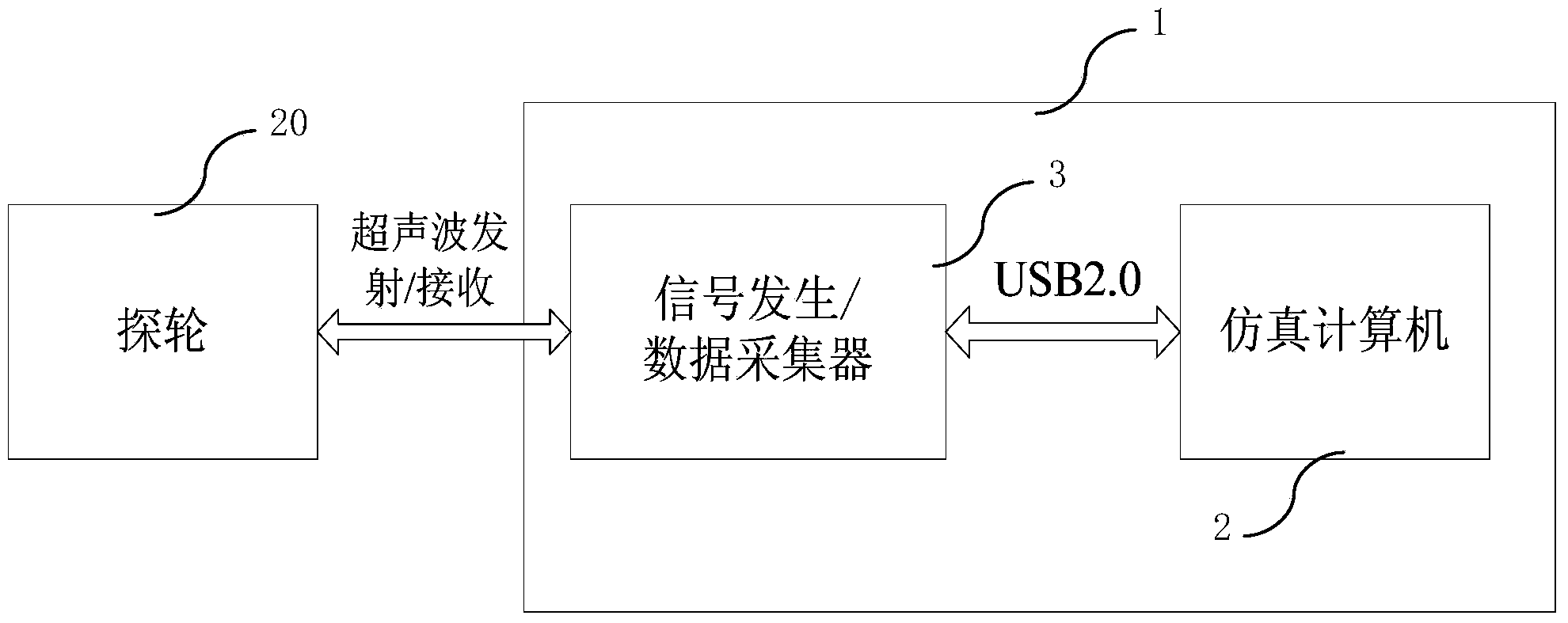

[0073] as attached Figure 13 As shown, a specific embodiment of the rail flaw detection simulation test method realized based on the device described in the specific embodiment of the present invention and the system thereof, the method includes the following steps:

[0074] S10: setting and storing the rail damage map through the simulation computer 2, digitally simulating the faulty rail 30 according to the unit length;

[0075] S20: Set the speed signal of the locomotive through the simulation computer 2, simulate the running of the locomotive, and sequentially generate the ultrasonic echo parameter data per unit length according to the rail damage map corresponding to the locomotive operating position, mainly including the ultrasonic echo parameter data corresponding to the fault characteristic point 6 Channel number, presence or absence of ultrasonic echo and ultrasonic echo delay value; locomotive running speed and ultrasonic echo parameter data are transmitted to signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com