Method for determining parameters of solid oxide fuel cell system

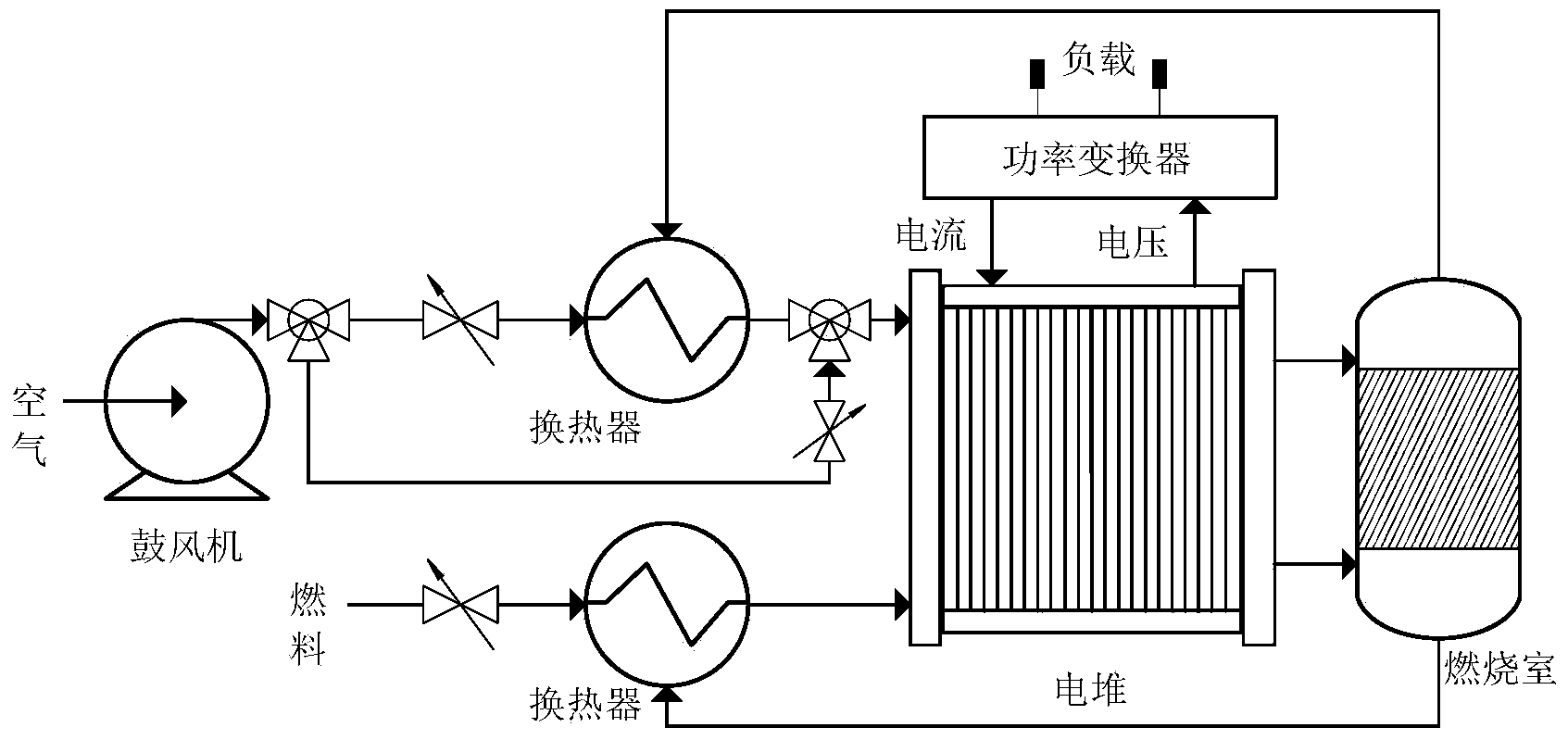

A fuel cell system, solid oxide technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as high temperature and suboptimal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

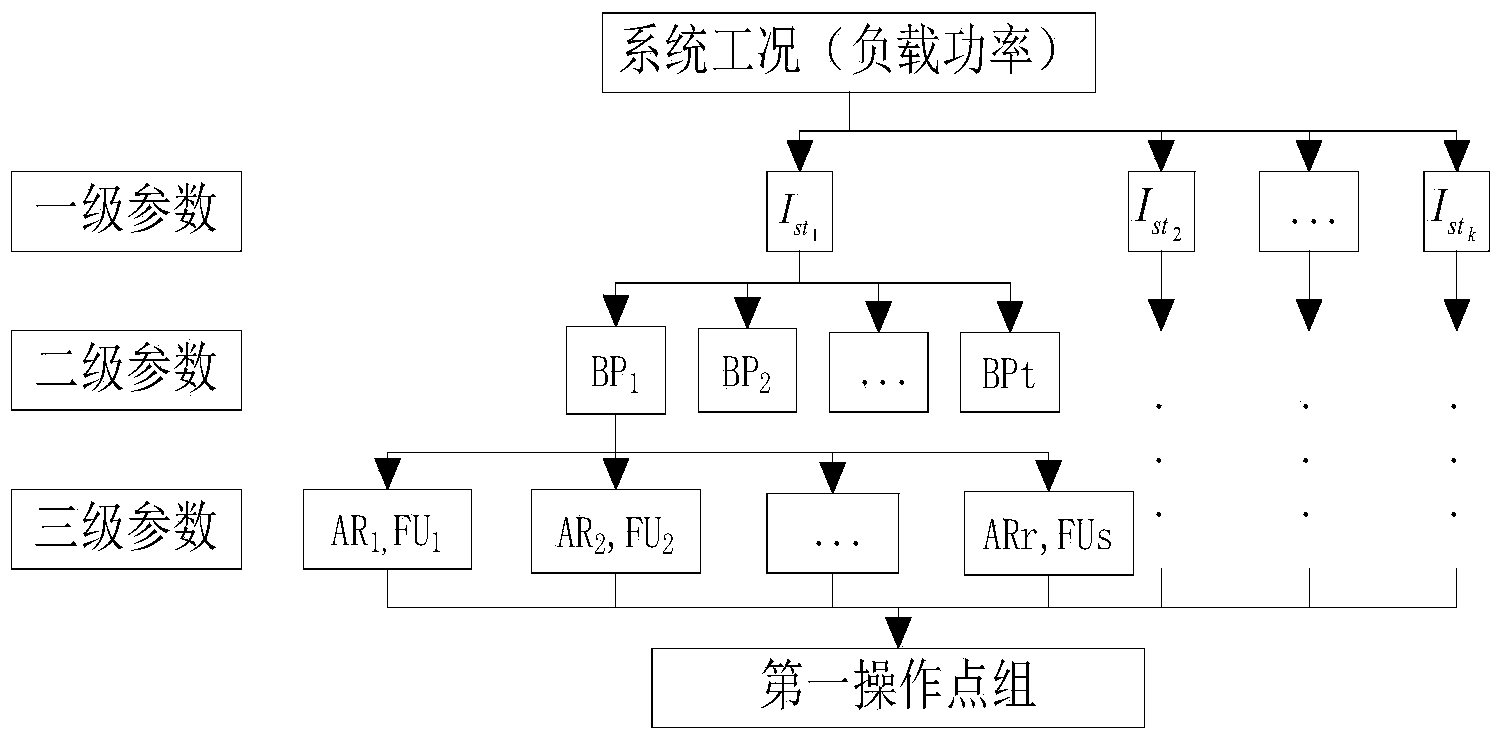

[0086] Example 1: First set four operating parameters, namely stack current I st , the bypass valve opening BP, the excess air ratio AR and the fuel utilization rate FU have a value range of I st =[10A, 80A], BP=[0.0, 0.3], AR=[6, 12], FU=[0.6, 0.9], the discrete precision is 2A, 0.05, 0.5 and 0.05 respectively, so the discrete numbers are respectively 36, 7, 13, 7. Each set of values after discretization of the four operating parameters constitutes the operating point (I st ,BP,AR,FU) for traversal collection, namely (10,0.0,6,0.6), (10,0.05,6,0.6), (10,0.05,6.5,0.6), (10,0.05,6.5,0.65 )...(80,0.3,12,0.9), so that the total number of operation points of the first operation point group is 22932.

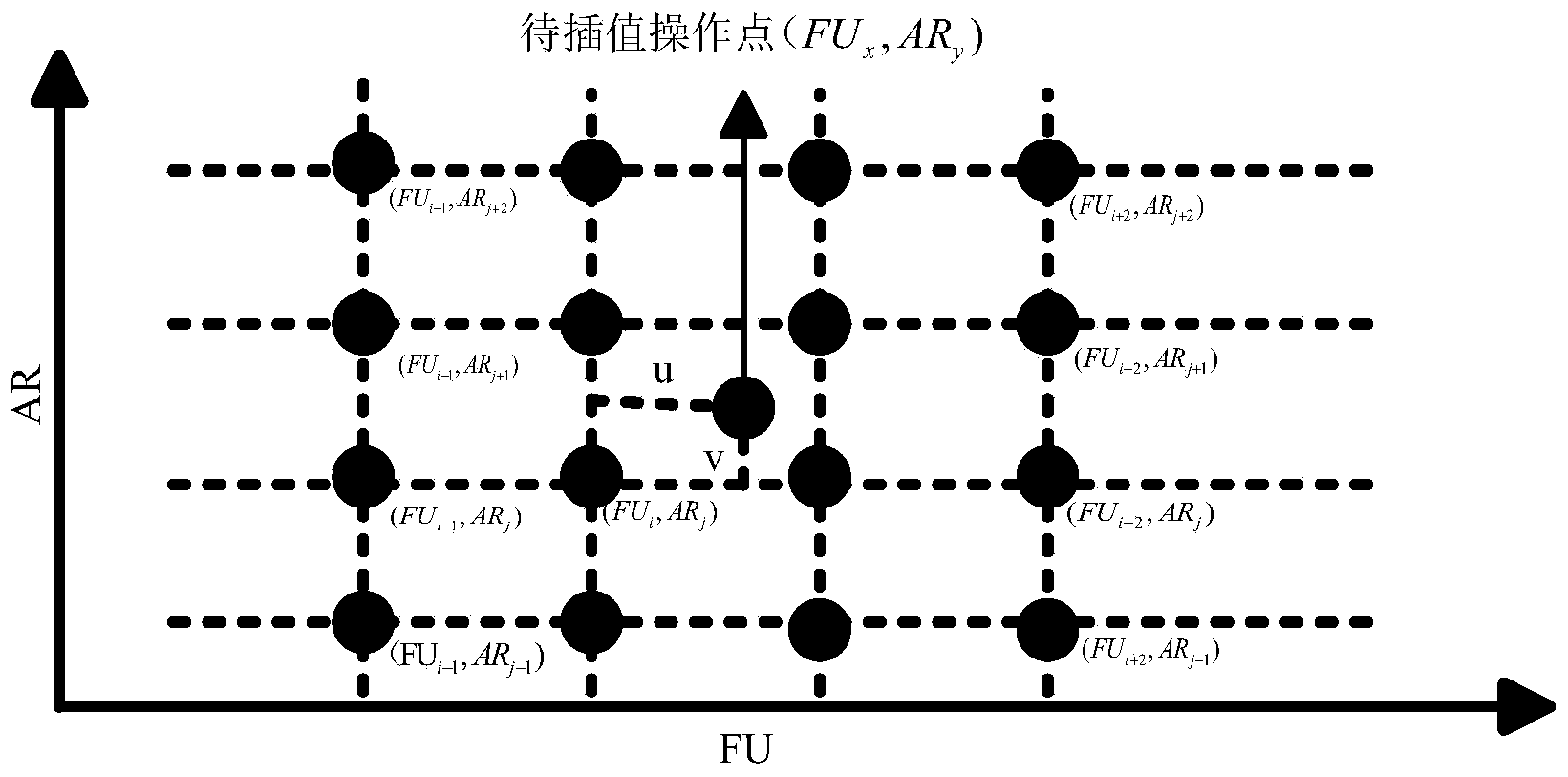

[0087] Then set the operating parameter stack current I st , the bypass valve opening BP, the excess air ratio AR and the fuel utilization rate FU interpolation accuracy are 2A, 0.05, 0.125 and 0.00625 respectively, that is, the operation parameter stack current I st and bypas...

example 2

[0089] Example 2: First set four operating parameters, namely stack current I st , the bypass valve opening BP, the excess air ratio AR and the fuel utilization rate FU have a value range of I st =[10A, 80A], BP=[0.0, 0.3], AR=[6, 12], FU=[0.6, 0.9], the discrete precision is 5A, 0.1, 1 and 0.1 respectively, so the discrete numbers are respectively 15, 4, 7, 4. Each set of values after discretization of the four operating parameters constitutes the operating point (I st ,BP,AR,FU) for traversal collection, namely (10,0.0,6,0.6), (10,0.1,6,0.6), (10,0.1,7,0.6), (10,0.1,7,0.7 )...(80,0.3,12,0.9), so that the total number of operation points of the first operation point group is 1680.

[0090] Then set the operating parameter stack current I st , bypass valve opening BP, air excess ratio AR and fuel utilization rate FU interpolation accuracy are 5A, 0.1, 0.25 and 0.02 respectively, that is, the operation parameter stack current I st and bypass valve opening BP accuracy rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com