Metal rubber optimal design and performance prediction method

A metal-rubber, optimization design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as inability to accurately predict the performance of metal-rubber, nonlinear deformation, difficulty in establishing mechanical analysis models, etc., and achieve the optimal design of metal-rubber. and performance forecast, the effect of breaking through technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

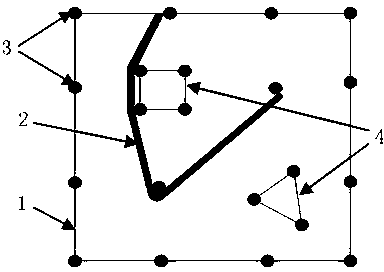

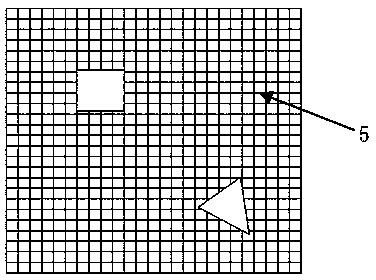

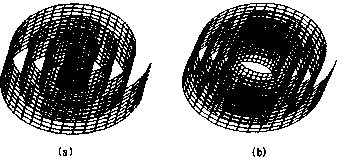

[0043] The present invention starts from the various laying or winding of metal rubber blanks, and first establishes a geometry that can fully reflect the influence of blank preparation process parameters (wire diameter, spiral coil diameter, blank winding or laying methods) by referring to the space parameterized model method. Secondly, starting from the geometric model of the blank, a mesh-free numerical analysis method with unique advantages in solving nonlinear deformation is introduced to deal with the deformation of all discrete units of turns, and then through the boundary constraints and internal contact lines of the metal rubber blank in the stamping die The constraints between the turns establish a dynamic numerical calculation model that can reflect the change of the metal rubber structure with the forming process; then use the output of the dynamic numerical calculation model to reconstruct the structure of the metal rubber product after stamping, and then analyze th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com