Attapulgite-carrier filter material for crude oil purification in edible vegetable oil production

A technology of edible vegetable oil and attapulgite, which is applied in the field of filter materials, can solve the problems of oil loss, large amount of waste water, high energy consumption, etc., and achieve the effects of reduced usage costs, strong purification ability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

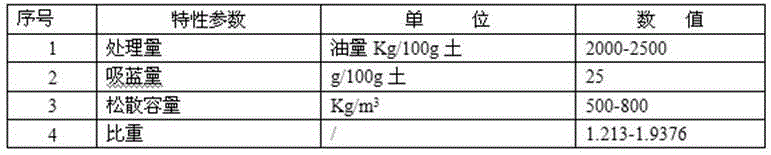

Image

Examples

Embodiment 1

[0022] Embodiment 1: the following steps produce attapulgite as the filter material of the carrier

[0023] (1) Attapulgite soil treatment: select the attapulgite original soil, fill the attapulgite original soil with pure water, soak for 48 hours, roll on the roller press, and grind it into powder by a grinder for later use;

[0024] (2) Pine wood powder treatment: choose pine wood powder with a particle size of ≤0.2mm, fill the pine wood powder with 30% acetic acid in mass concentration, soak and stir for 48 hours, press filter and dry for later use;

[0025] (3) Weighing and mixing: Weigh each component according to mass percentage: attapulgite clay 54%, polyethylene glycol 2M 15%, carbon black 9%, calcium chloride 14%, pine powder 8%, with a mixer mix;

[0026] (4) Granulation: The mixture in step (3) is made of spherical particles with a particle size of 1.00 mm to 2.00 mm by a granulator;

[0027] (5) Calcination: the spherical particles in step (4) are calcined in a c...

Embodiment 2

[0030] Embodiment 2: the following steps produce attapulgite as the filter material of the carrier

[0031] (1) Attapulgite soil treatment: select the attapulgite original soil, fill the attapulgite original soil with pure water, soak for 48 hours, roll on the roller press, and grind it into powder by a grinder for later use;

[0032] (2) Pine wood powder treatment: choose pine wood powder with a particle size of ≤0.2mm, fill the pine wood powder with 30% acetic acid in mass concentration, soak and stir for 48 hours, press filter and dry for later use;

[0033] (3) Weighing and mixing: Weigh each component according to mass percentage: attapulgite clay 54%, polyethylene glycol 2M 15%, carbon black 9%, calcium chloride 14%, pine powder 8%, with a mixer mix;

[0034] (4) Granulation: The mixture in step (3) is made of spherical particles with a particle size of 1.00 mm to 2.00 mm by a granulator;

[0035] (5) Calcination: the spherical particles in step (4) are calcined in a c...

Embodiment 3

[0038] Embodiment 3: the following steps produce attapulgite as the filter material of the carrier

[0039] (1) Attapulgite soil treatment: select the attapulgite original soil, fill the attapulgite original soil with pure water, soak for 48 hours, roll on the roller press, and grind it into powder by a grinder for later use;

[0040] (2) Pine wood powder treatment: choose pine wood powder with a particle size of ≤0.2mm, fill the pine wood powder with 30% acetic acid in mass concentration, soak and stir for 48 hours, press filter and dry for later use;

[0041] (3) Weighing and mixing: Weigh each component according to mass percentage: attapulgite clay 54%, polyethylene glycol 2M 15%, carbon black 9%, calcium chloride 14%, pine powder 8%, with a mixer mix;

[0042] (4) Granulation: The mixture in step (3) is made of spherical particles with a particle size of 1.00 mm to 2.00 mm by a granulator;

[0043] (5) Calcination: the spherical particles in step (4) are calcined in a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com