Combined die cutting die

A technology of cutting die and combined die, applied in metal processing and other directions, can solve the problems of low product accuracy, short service life, continuous interface, etc., and achieve the effect of improving production efficiency, reducing production cost, and reducing dimensional errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

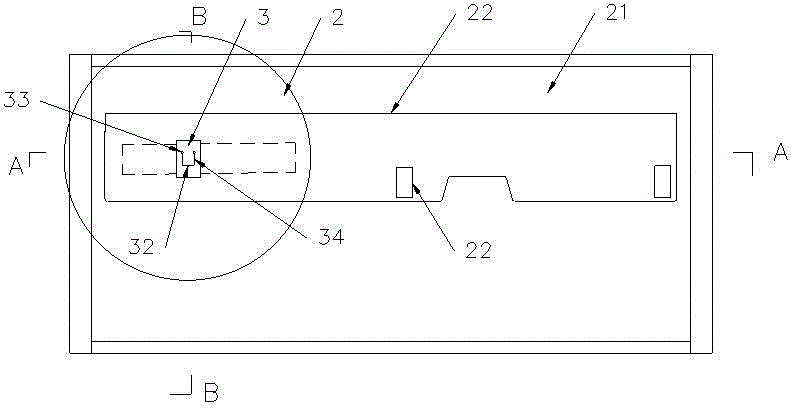

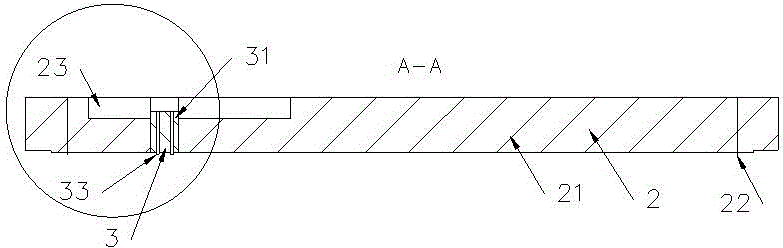

[0018] see Figure 1-3 A combined die-cutting die, which includes a laser die 2 and an etching die 3. The laser knife template 2 includes a wooden board (laser knife template) 21 and a blade 22 embedded in the gap on the surface of the laser knife template.

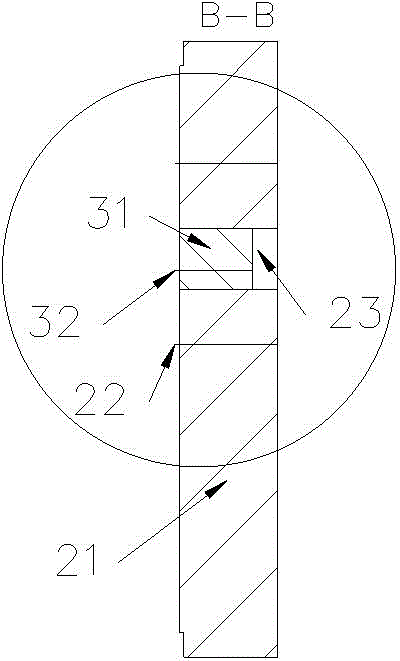

[0019] see Figure 4-6 , The etching knife template 3 includes an etching knife template 31 and a blade edge 32 formed on the surface of the etching knife template. The knife edge 32 has two circular blanking through-hole knives 33 , three straight-line knives 34 , and an arc-shaped connection between two adjacent straight-line knives 34 . The arc-shaped connection part is a circular arc with a radius of 1mm. The radius of circular blanking through-hole knife 33 is 2mm.

[0020] The etching knife template 31 is detachably embedded in the plank (laser knife template) 21. On the back side of the embedded plank (laser knife template) 21, there is a waste discharge card slot 23 communicating with the blanking circular ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com