Method for preventing large hierarchical aircraft tire cord fabric backward-packed ends from being disengaged

A technology of aviation tires and turned-up ends, which is applied to the reinforcement layer of pneumatic tires, tire parts, transportation and packaging, etc. It can solve problems such as tire blowouts, hidden safety hazards, and disengagement, so as to ensure the strength and load of the carcass Ability to prevent delamination and bulging, and the effect of not being easy to disengage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

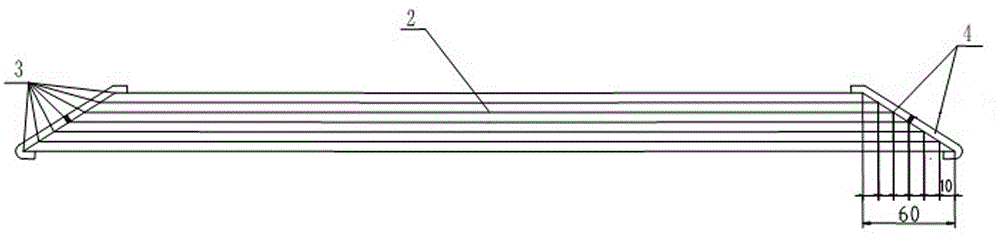

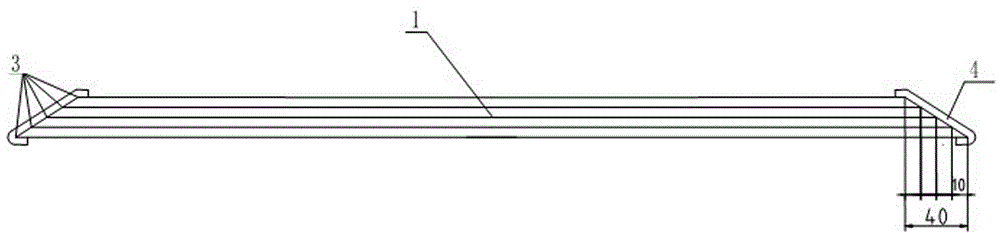

[0014] refer to Figure 1-2 , a method capable of effectively preventing large-level aircraft tire ply turns-up ends from coming off. The tire includes 12 layers of carcass cords, each layer of ply turns-up ends, and a ply end sealing film. When laminating the process, the cords of the 1st to 6th layers are 1# reversed cord drum 1, the cords of the 7th to 10th layers are 2# reversed cord drums 2, and the cords of the 11th to 12th layers are 3# positive corded drums. The bonding difference between layers of cords is 10mm. Set two ply end sealing films 4 with a thickness of 0.5mm and a width of 35mm at the ends 3 on both sides of the 1# cord barrel, that is, set a piece of film 4 between the ends of every three layers of cord, and between two pieces of film 4 For seamless docking, there are a total of 4 films 4 in the entire cord tube. Set one ply end sealing film 4 with a thickness of 0.5 mm and a width of 50 mm at the ends of both sides of the 2# cord barrel 2, and there are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com