Automatic tea leaf packaging machine

A tea bag, automatic technology, applied in the directions of packaging, transportation and packaging, packaging item types, etc., can solve the problems of uneven distribution of tea amount, inability to accurately control the amount of tea feeding, etc., to reduce labor intensity, reasonable structure design, Easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

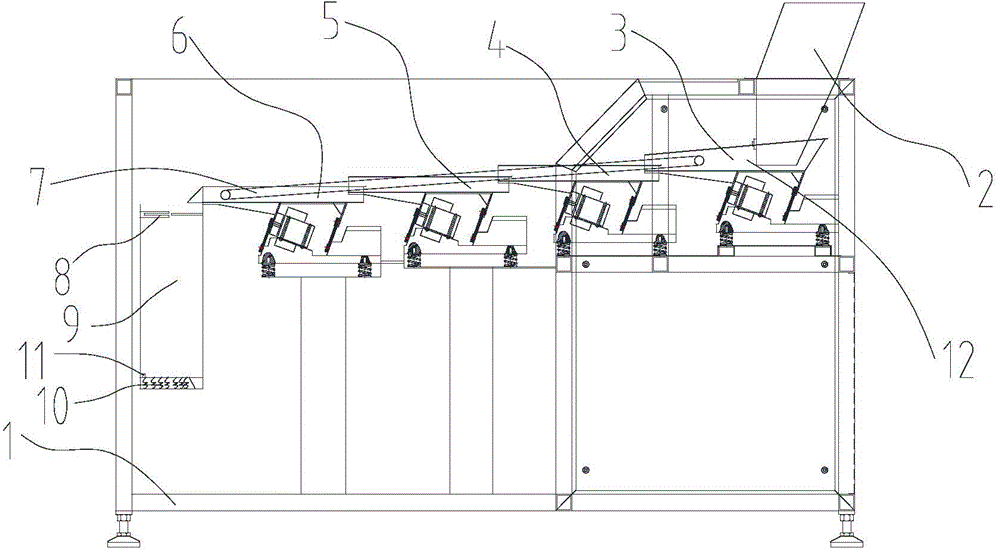

[0010] Embodiment 1, an automatic tea packaging machine, which includes a frame, the upper end of the frame is provided with a feed bin, the lower end of the feed bin is provided with a large vibrating feeder, and the large vibrating feeder The outlet of the feeder is provided with a medium vibrating feeder, a small vibrating feeder, and a micro-vibrating feeder in turn. The large vibrating feeder and the micro-vibrating feeder are connected by a connecting rod. A hopper door is provided at the outlet of the micro-vibration feeder, a funnel is provided at one end of the hopper door, and a scale hopper is provided at the outlet of the funnel, and an inductor is provided on the scale hopper.

[0011] Both sides of the large vibrating feeder, medium vibrating feeder, small vibrating feeder, and micro vibrating feeder are respectively provided with guardrails.

[0012] When the device is working, it pours the tea leaves to be packaged through the feeding bin, and the large vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com