Automatic unpacking and chopping equipment for bagged materials

An automatic and equipment technology, applied in the direction of unstacking of objects, conveyor objects, transportation and packaging, etc., can solve the problems of heavy workload, heavy environmental pollution, and many safety hazards, and achieve the effect of accurately controlling the amount of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

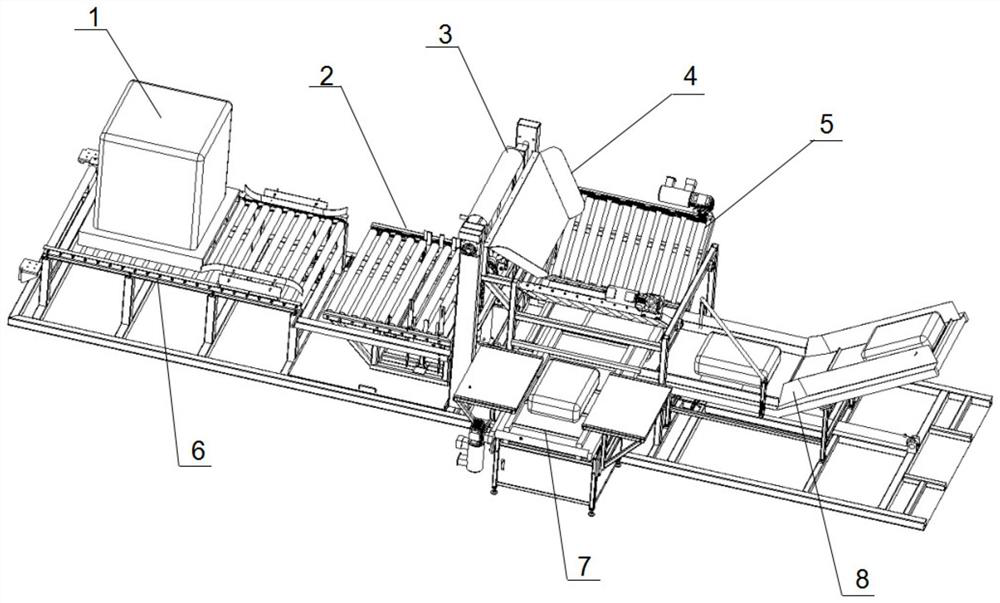

[0063] In this embodiment, an automatic dismantling and chopping device for bagged materials 1 is specifically provided, through which the bagged materials 1 can be dismantled and chopped. The bagged material 1 that is packaged in one small bag as a whole, after it is disassembled and chopped, it can realize blanking of each small bag material. Such as figure 1 As shown, the automatic dismantling and chopping equipment mainly includes: feeding conveyor line 6, intermediate conveyor line 2, turning mechanism 3, rubbing material conveyor line 5 and discharge conveyor line 8, and its specific design is as follows:

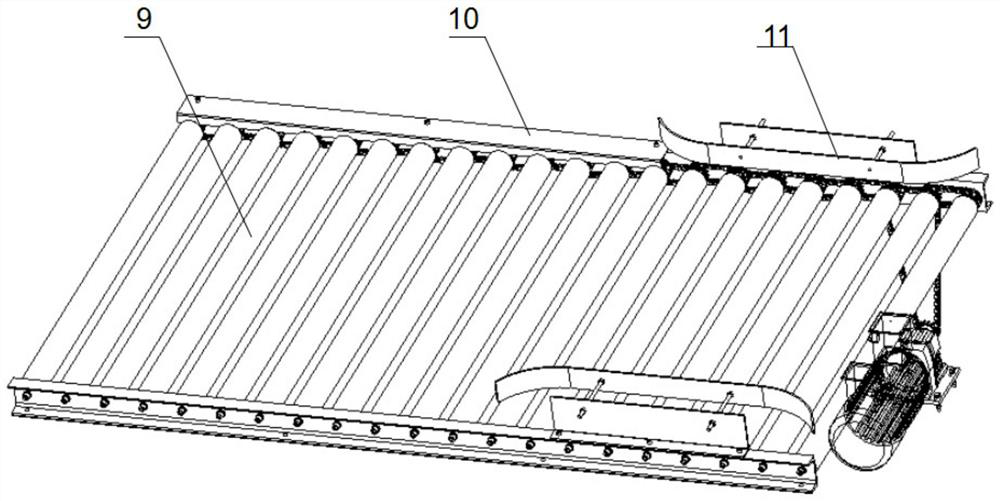

[0064] ① Feed conveyor line

[0065] Such as figure 2 As shown, the feeding conveying line 6 is used to transfer the external bagged material 1 to the automatic dismantling equipment, and the feeding conveying line 6 is the inlet side of the bagged material 1, and the bagged material 1 is placed on the tray , lift the pallet by a forklift and place the pallet on t...

Embodiment 2

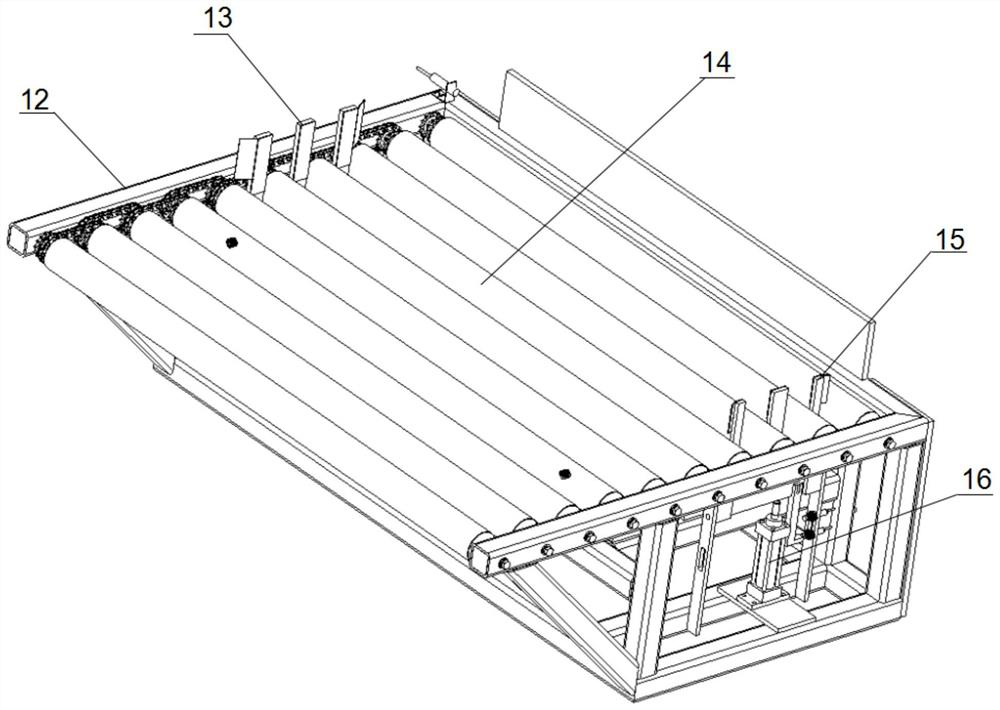

[0087] On the basis of embodiment 1, in order to further improve the automatic dismantling and chopping equipment during operation, it can also possess the function of manual feeding, therefore, as Image 6 As shown, the automatic chopping equipment also includes:

[0088] The manual feeding conveyor line 7, the discharge side of the manual feeding conveyor line 7 is located above the discharge conveyor line 8 and the discharge side does not interfere with the rubbing material discharge port. The concrete design of described manual feeding conveying line 7 is as follows:

[0089] Manual feeding main frame 26 and the feeding conveyer belt 25 that is located on the manual feeding main frame 26, one end of described feeding conveyer belt 25 is positioned at the top of discharge conveying line 8, and the both sides of the other end are provided with material placing table 23, material The placement table 23 is used for temporary storage of small batches of materials. The feeding...

Embodiment 3

[0099] In embodiment 1, the mode of overturning is adopted to realize automatic blanking, as Figure 10 As shown, in this embodiment, another kind of blanking method is provided, and its specific structure is:

[0100] Install the unloading rack on the frame, the intermediate conveying line is slid on the unloading rack, and the unloading rack is provided with a lifting hydraulic cylinder, and the telescopic rod end of the lifting hydraulic cylinder is rotated to be provided with a sprocket, The sprocket is equipped with a chain engaged with it, and the intermediate conveying line is driven to slide by the chain;

[0101] A slideway is provided on the blanking side of the blanking frame, the slideway is located on the blanking side of the intermediate conveying line and the slideway corresponds to the rubbing conveying line;

[0102] A push cylinder corresponding to the blanking station of the unloading frame is installed on the frame, and one end of the push cylinder is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com