Novel feeding system of oil-containing sludge high-speed steam processing system

A technology of processing system and feeding system, which is applied in the field of new feeding system, can solve the problems of blockage and shutdown of the processing chamber, affect the processing efficiency and work safety, affect the operation of the processing chamber, etc., and achieve the effect of improving the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

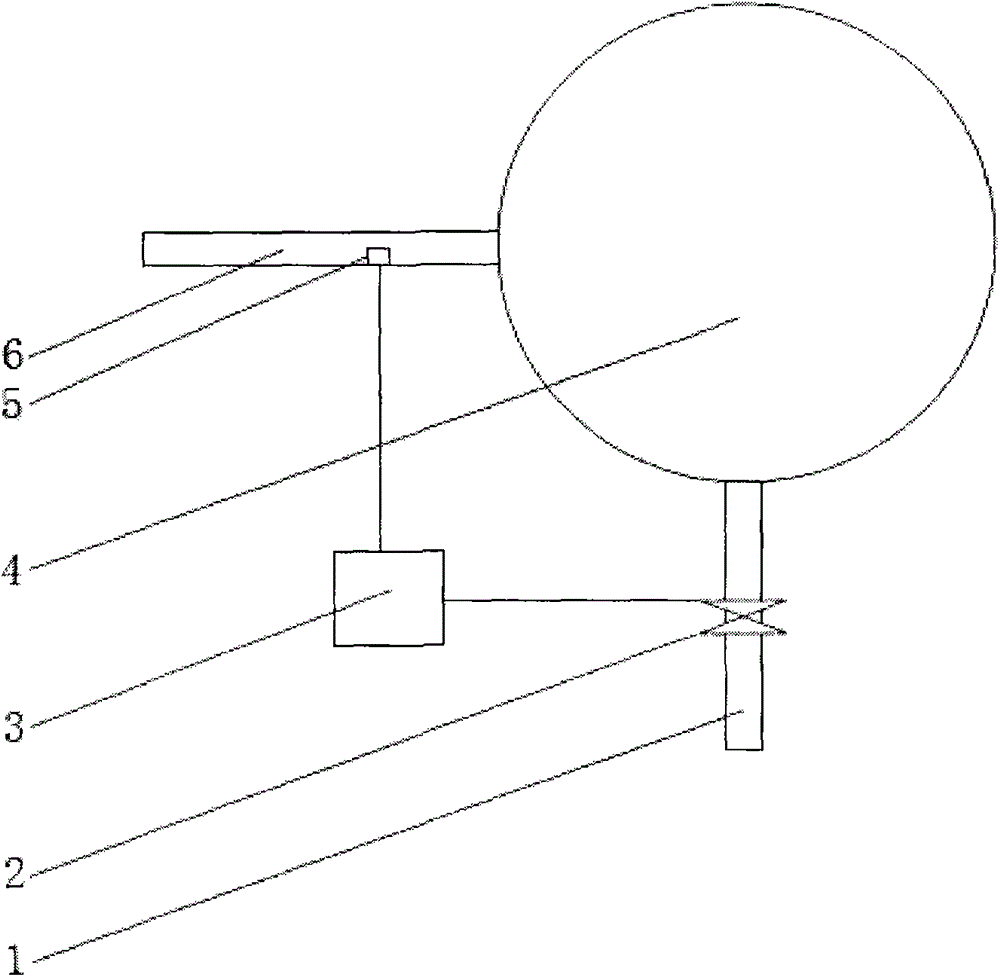

[0011] Such as figure 1 As shown, a new feed system of a high-speed steam treatment system for oily sludge includes a feed pipe 1 vertically installed on the upper part of the treatment chamber 4 of the high-speed steam treatment system for oily sludge;

[0012] A solenoid valve switch 2 is installed on the feed pipeline 1;

[0013] A discharge sensor 5 is installed in the discharge pipeline 6 of the treatment chamber 4;

[0014] The discharge sensor 5 and the electromagnetic valve switch 2 are connected to the automatic controller 3 at the same time.

[0015] The novel feeding system of a high-speed steam treatment system for oily sludge described in this patent solves the problem that the sludge easily sticks to the treatment room caused by the parallel arrangement of the previous pipelines by installing the feed pipe 1 vertically on the upper part of the treatment chamber 4 4 disadvantages such as inner wall and low separation efficiency; at the same time, by installing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com