Method for preparing pyridine compounds from polyol compounds

A technology of polyol compounds and polyols, applied in the direction of organic chemistry, can solve problems such as difficult to meet market demand, achieve the effects of reducing corrosion and pollution, avoiding pretreatment steps, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this example, a quartz tubular reactor with a diameter of 10 mm and a length of 250 mm was used. Loading H-ZSM-5 catalyst (SiO 2 :Al 2 o 3 =25-200) to produce a fixed bed supported by quartz wool. Install the quartz reactor in a temperature-controlled furnace. Reactor temperature was monitored by thermocouples inserted into the surface of the temperature-controlled furnace packed bed.

[0036] During operation, the raw material is a polyol compound, and a reactive nitrogen compound is used as a carrier gas, and its flow rate is controlled by a flow meter. The liquid feedstock was introduced into the carrier gas by a syringe pump and transported to the reactor. The reaction temperature is 200-800°C, and the flow rate of the carrier gas is 5-200ml / min. Liquid products flow from the reactor to the condenser and gaseous products are collected in gas sampling bags. Liquid and gaseous products were analyzed using a gas chromatograph.

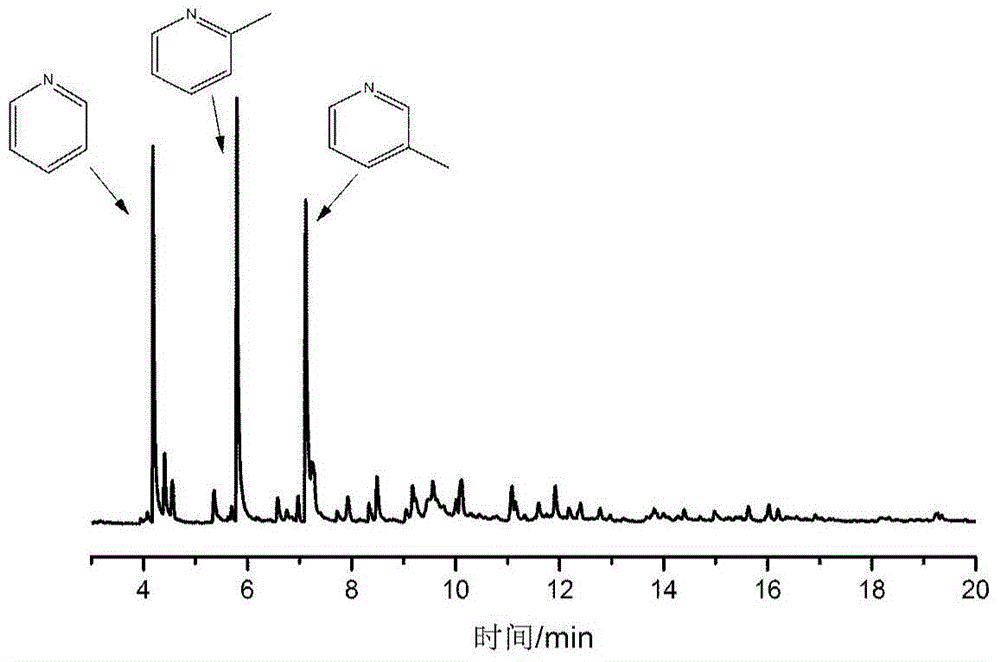

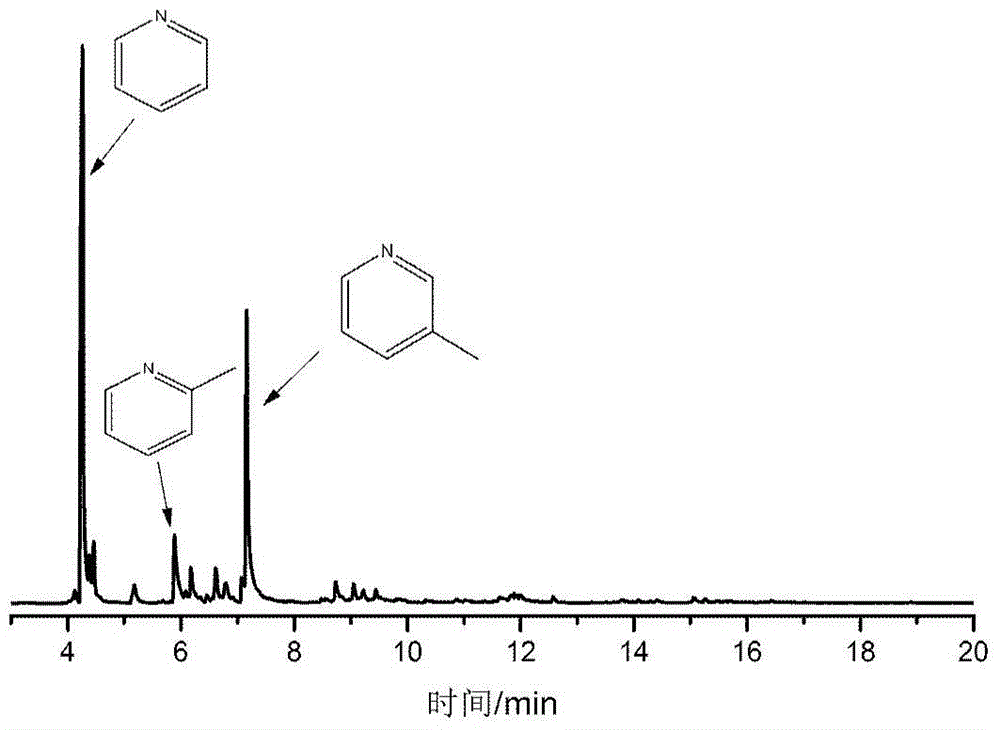

[0037]As representative of se...

Embodiment 2

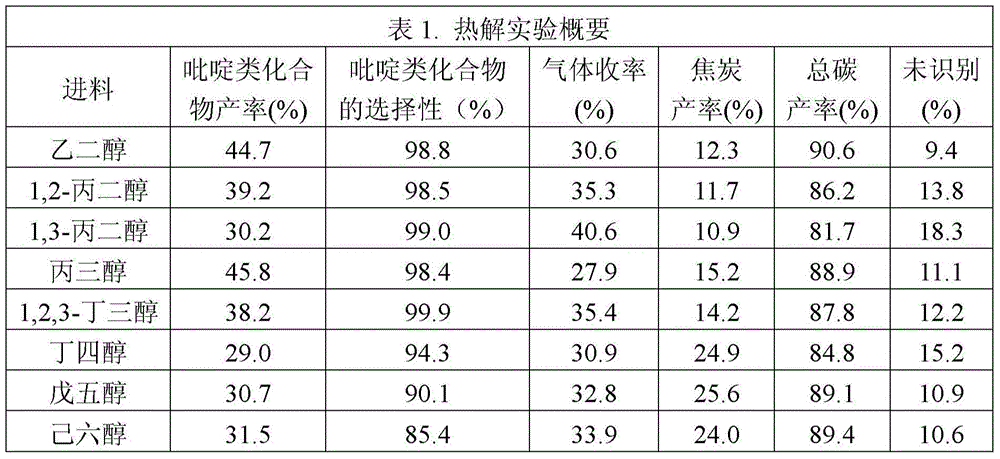

[0041] Introduce the liquid raw material into the carrier gas through the syringe pump, test ethylene glycol, glycerol, 1,2-propanediol, 1,3-propanediol, 1,2,3-butanetriol, butylene glycol, pentapentyl pentaol, hexyl Yields of pyridines produced by catalytic pyrolysis of different starting materials such as hexaols. Table 1 shows that the liquid products are essentially pyridines.

[0042]

[0043] Reaction conditions: the reaction temperature is 500°C, the catalyst is H-ZSM-5 (SiO 2 :Al 2 o 3 =25), consumption is 1g, WHSV=1, ammonia gas flow=40ml / min.

Embodiment 3

[0045] This example studies the effect of reaction temperature on product yield. Table 2 shows that the yield of pyridine compounds will increase with the increase of temperature, but the continuous increase will make the yield of pyridine compounds decrease. And when the temperature is above 500°C, the selectivity of pyridine compounds decreases with the increase of temperature.

[0046]

[0047] Reaction conditions: the reaction raw material is glycerol, the catalyst is H-ZSM-5 (SiO 2 :Al 2 o 3 =25), consumption is 1g, WHSV=1, ammonia gas flow=40ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap