Brewing machine

A technology of brewing machines and tanks, which is applied in the field of brewing machines, can solve the problems of incomplete fermentation, slow heating speed, and many pipelines, and achieve the effects of improving heating uniformity, preventing excessive air pressure, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

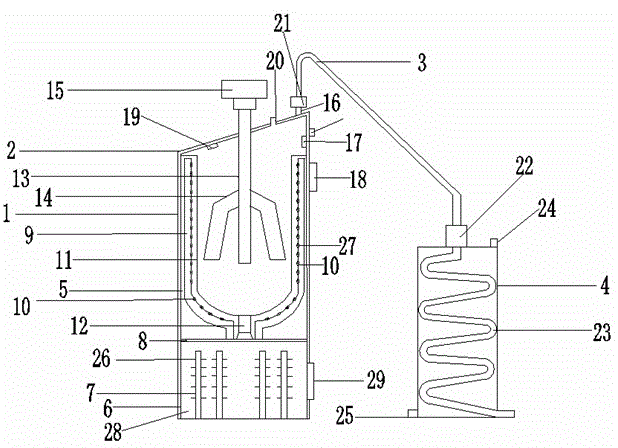

[0015] Illustrate the present invention in conjunction with accompanying drawing, the structure of the present invention comprises tank body 1, tank body upper cover 2, steam conduit 3, condensing chamber 4 and agitator, described tank body 1 upper end face is inclined-plane, tank body 1 is divided into by dividing plate 8 Two parts, the upper part is the fermentation chamber 5, the lower part is the heating chamber 6, the agitator includes the agitator shaft 13 and the mixing plate 14 arranged on it, the upper end of the condensation chamber is provided with a water inlet 24, and the lower end is provided with an outlet. The nozzle 25 is characterized in that: the heating chamber 6 is provided with a heating pipe 7 and a heating medium 28, and the fermentation chamber 5 is provided with a fermentation chamber 11, a forward-rotating motor 12 and a plurality of hollow cooling pipes 9, and the forward-rotating motor 12 Installed on the partition plate 8, the output shaft of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com