Sewing machine frame and sewing machine pressor foot lifting device thereof

A presser foot lifter and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of complex presser foot lifter structure, inaccurate height setting, etc., and achieve compact structure, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

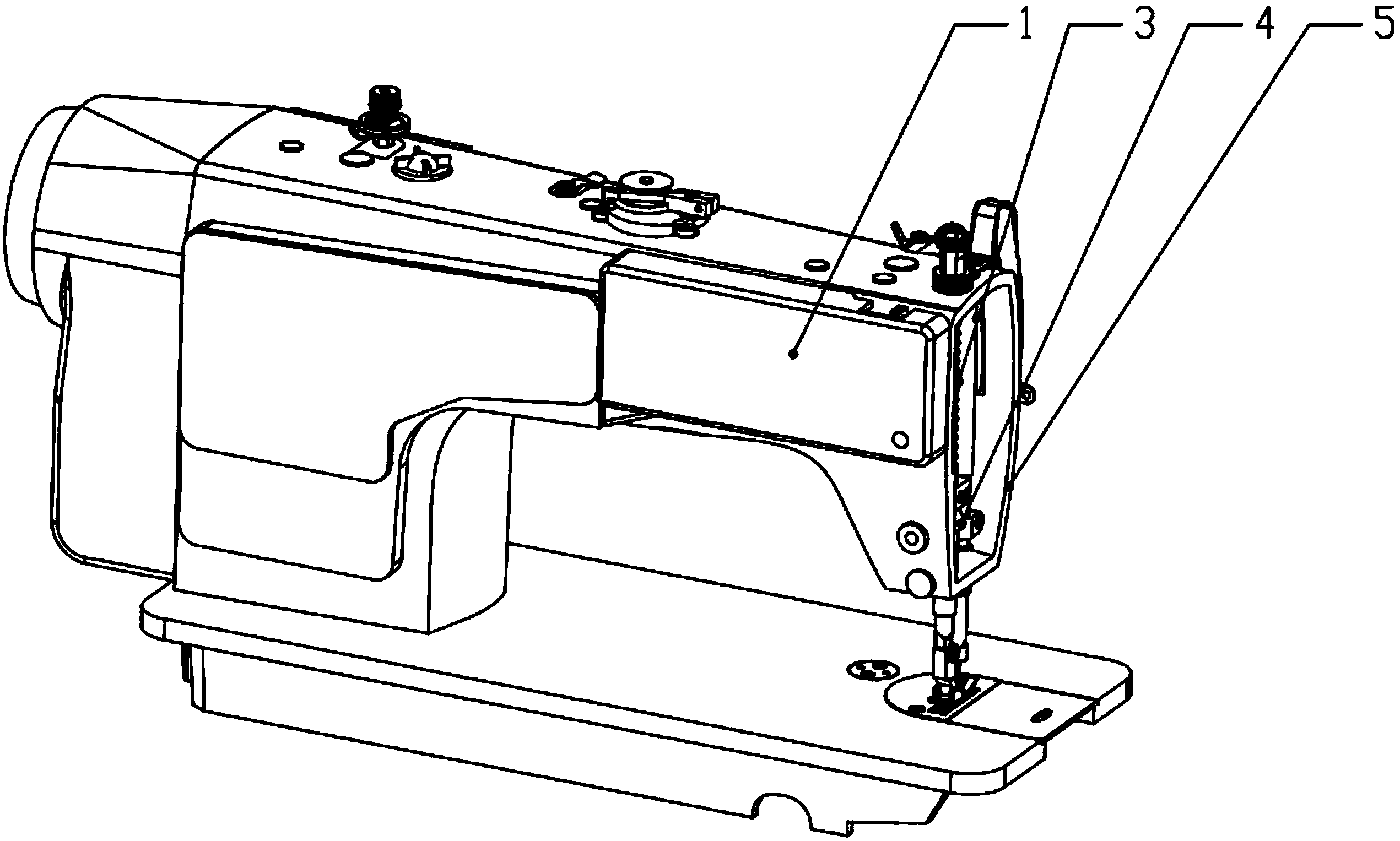

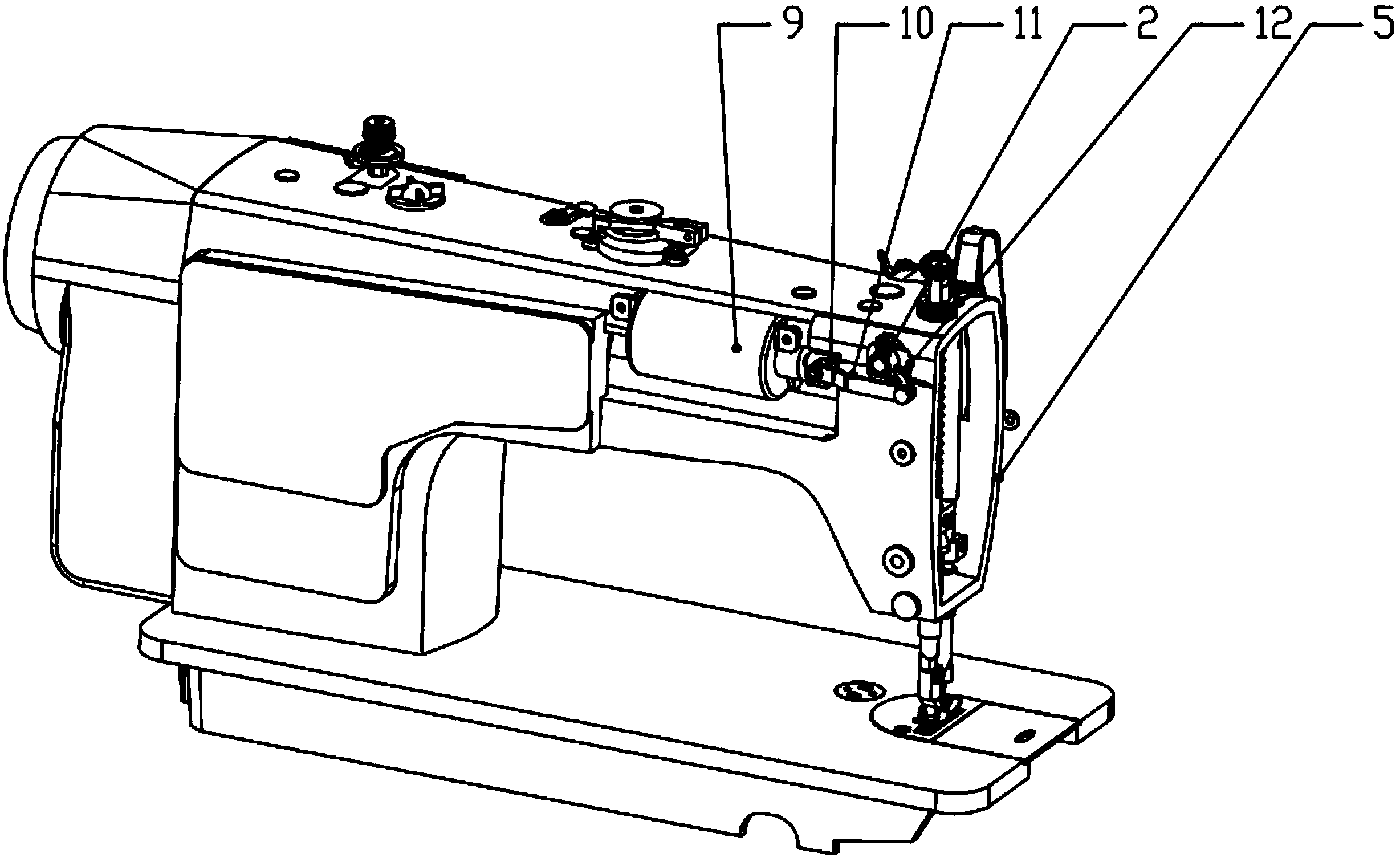

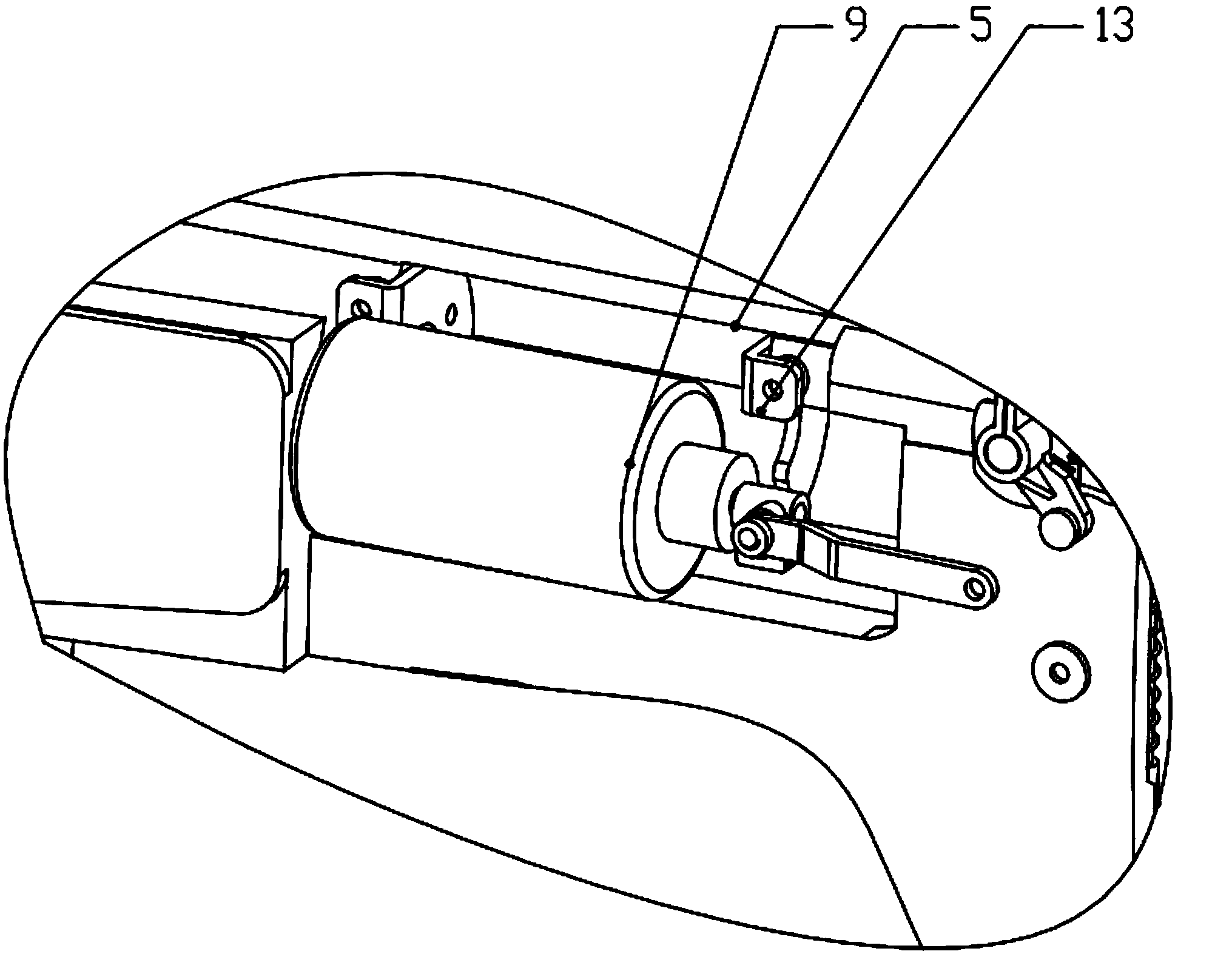

[0032] In the figure, a sewing machine presser foot lifting device includes a frame 5, a presser foot assembly 4, a presser foot lifting crank 6, a presser foot lifting connecting rod 7, and a presser foot lifting push rod 8. In the present invention, the presser foot assembly 4, lifting foot Presser foot connecting rod 7, presser foot lifting push rod 8, electromagnet crank 2 are all known structures and technologies.

[0033] Frame 5 among the present invention (as Figure 5 As shown) adopts a unique structure, including the frame body, the frame body is divided into a beam 5-1 and a vertical beam 5-2, the inside of the beam and the vertical beam is a hollow structure, close to the end of the presser foot assembly, at one end of the beam Groove 5-3 is provided, and electromagnet can be placed in the groove, and outer cover can be arranged on the outside of electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com