Corner upright post, two-side oblique beam and drainage channel cross beam connecting structure of sunlight house

A technology of corner columns and connecting structures, which is applied in the direction of building construction and construction, can solve the problems of the overall strength of easily damaged timber components, affect the quality of installation and construction, and poor stability and integrity, so as to improve the interior decoration effect and improve the processing quality. Accuracy and production efficiency, and the effect of improving installation quality and progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

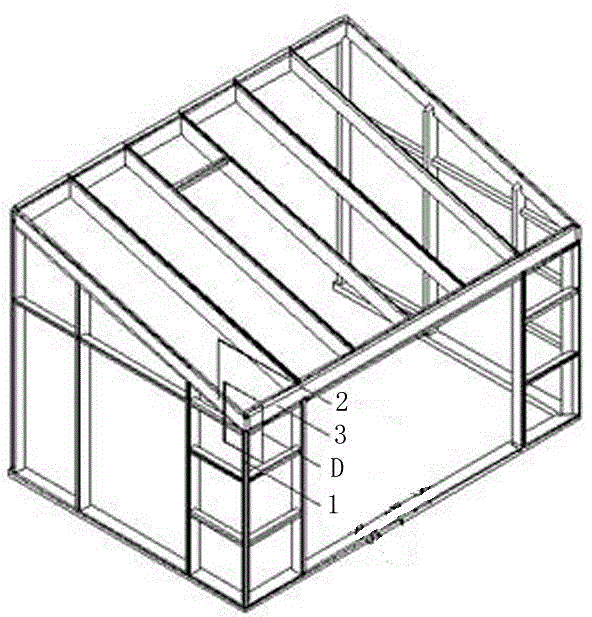

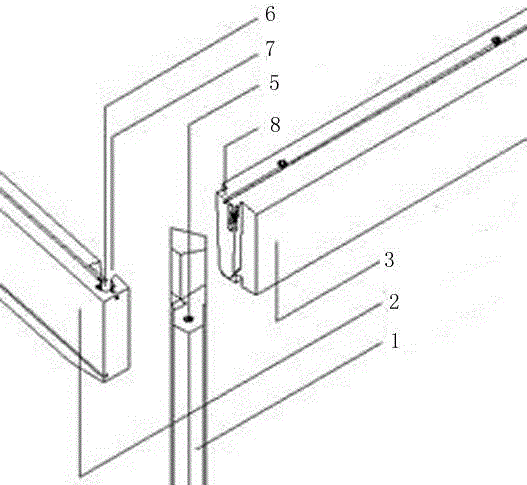

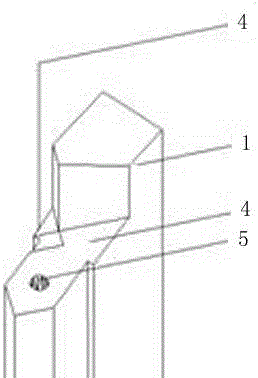

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the connection structure between the corner column of the sun room and the inclined beams on both sides and the gutter beam of the present invention mainly includes a corner column 1, and the upper ends of the corner column 1 are respectively connected with two sides that intersect and contact each other. The connecting end of the slanting beam 2 and the gutter beam 3, the upper end of the corner column 1 is provided with a mounting surface 4 that is in contact with the connecting ends of the slanting beam 2 on both sides and the gutter beam 3 respectively, and on both sides There is a lower round hole 5 on the mounting surface 4 where the connecting ends of the inclined beam 2 are in contact, see image 3 shown;

[0016] Figure 4 As shown, the connecting ends of the inclined beams 2 on both sides are also correspondingly provided with an upper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com