Bamboo-wood-filled buckling restrained support

A buckling restraint, bamboo and wood technology, applied in the field of civil engineering, can solve the problems of unreusable concrete, heavy steel pipe restraint components, unfavorable environmental protection, etc., to avoid electrochemical corrosion, achieve lightweight, and reduce weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

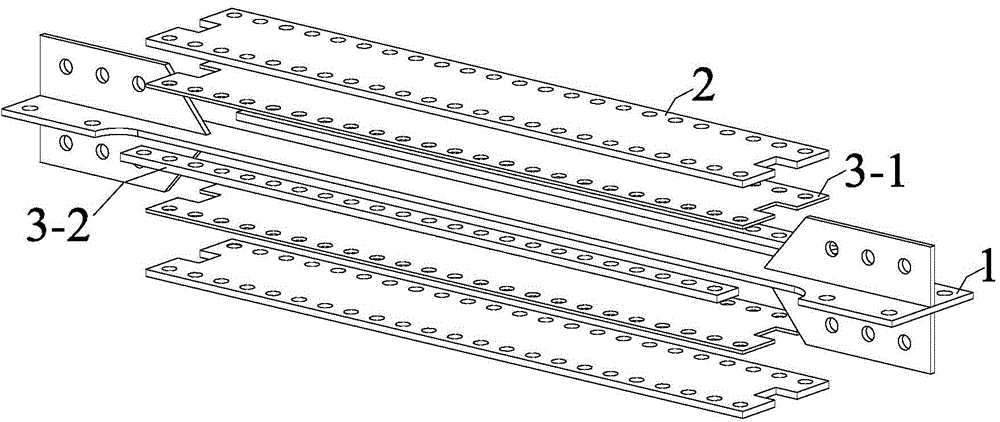

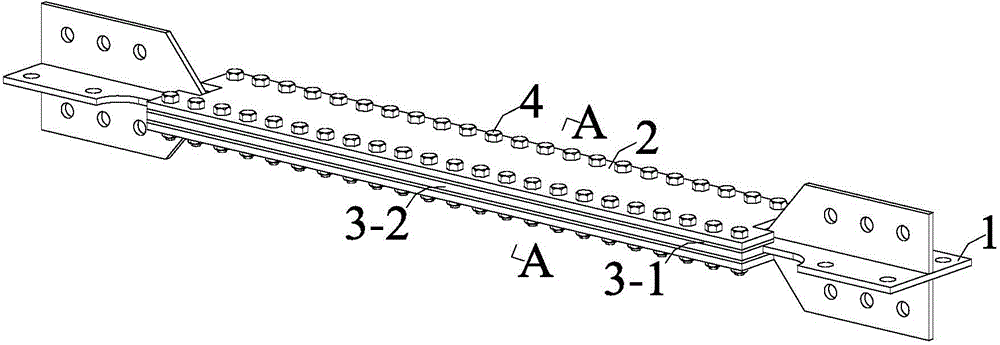

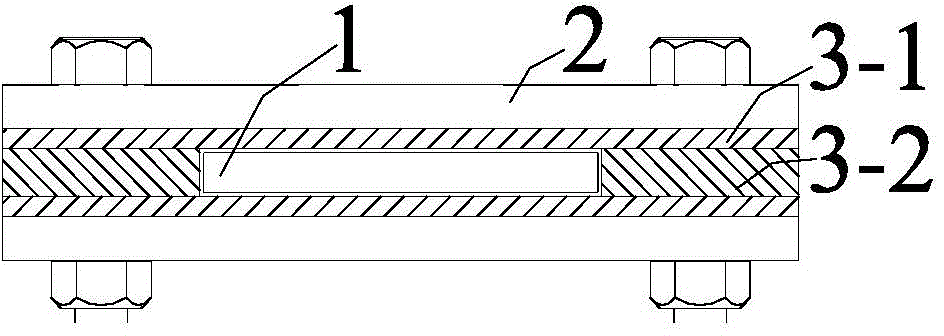

[0030] Such as Figure 1-3 As shown, a bamboo-wood filled buckling-restrained support includes a metal core component 1, bamboo-wood fiber filled components and peripheral constraint components;

[0031] The metal core component 1 adopts a straight member, the peripheral constraint component is a peripheral constraint flat plate 2, and the bamboo fiber filling component includes a filling flat plate 3-1 and a filling slat 3-2;

[0032] The metal core part 1 is arranged between two filling flat plates 3-1, the width of the filling flat plate 3-1 is greater than the width of the inline member of the metal core part 1, and the gap between the two filling flat plates 3-1 is provided with filling The slat 3-2; the filling plate 3-1 and the filling slat 3-2 are in close contact with the surface of the in-line member, leaving a gap; the peripheral constraining plate 2 is close to the outside of the filling plate 3-1, And the bolts 4 pass through the peripheral constraining plate 2, ...

Embodiment 2

[0034] Such as Figure 4-5 As shown, a bamboo-wood filled buckling-restrained support includes a metal core component 1, bamboo-wood fiber filled components and peripheral constraint components;

[0035] The metal core part 1 adopts a cross-shaped member, and the bamboo and wood fiber filling part includes a filling body 3-3 and a filling slat 3-2;

[0036] The four corners of the cross-shaped member of the metal core component 1 are respectively provided with four filling bodies 3-3, the width of each filling body 3-3 is greater than the length of the adjacent cross-shaped member, and the four filling bodies 3-3 Filling slats 3-2 are arranged in the gaps between them; the filling body 3-3 and the filling slats 3-2 are in close contact with the surface of the cross-shaped member, and a gap is left; the peripheral constraint parts are close to the filling body 3 -3 and fill the periphery of slats 3-2; the peripheral constraining parts use steel plates 2-1 and channel steels 2-...

Embodiment 3

[0038] Such as Figure 6-7 Shown: this embodiment is the same as the rest of embodiment 2, the difference is that: the peripheral constraining components are welded between steel plates 2-1 to form a box-shaped constraining structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com