Hydraulic system of stepless speed regulation hydropress

A technology of stepless speed regulation and hydraulic system, applied in the field of hydraulic system of hydraulic presses, can solve the problems of low control accuracy and poor anti-eccentric load capacity, so as to solve the problem of low control accuracy, improve synchronization accuracy, and improve anti-eccentric load capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

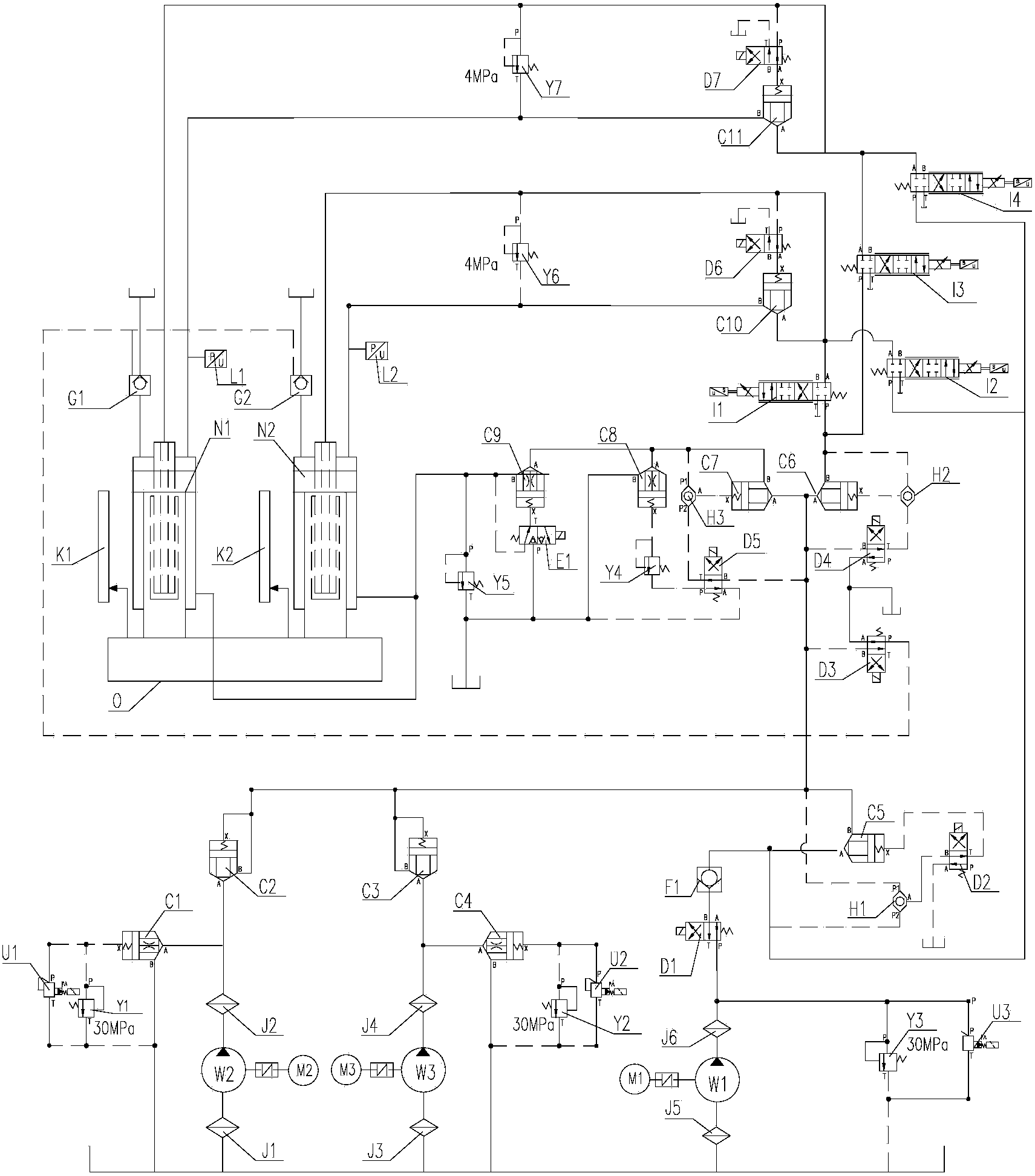

[0030] figure 1 The oil ports of the hydraulic valves are marked in accordance with GB-T17490-1998.

[0031] like figure 1 As shown, the present invention includes a first hydraulic cylinder N1, a second hydraulic cylinder N2, a slider O, a first flow pump W1, a second flow pump W2, a third flow pump W3, a first servo valve I1, a second servo valve I2, the third servo valve I3, and the fourth servo valve I4, the first flow pump W1, the second flow pump W2, and the third flow pump W3 are respectively driven by the first motor M1, the second motor M2, and the third motor M3 ;

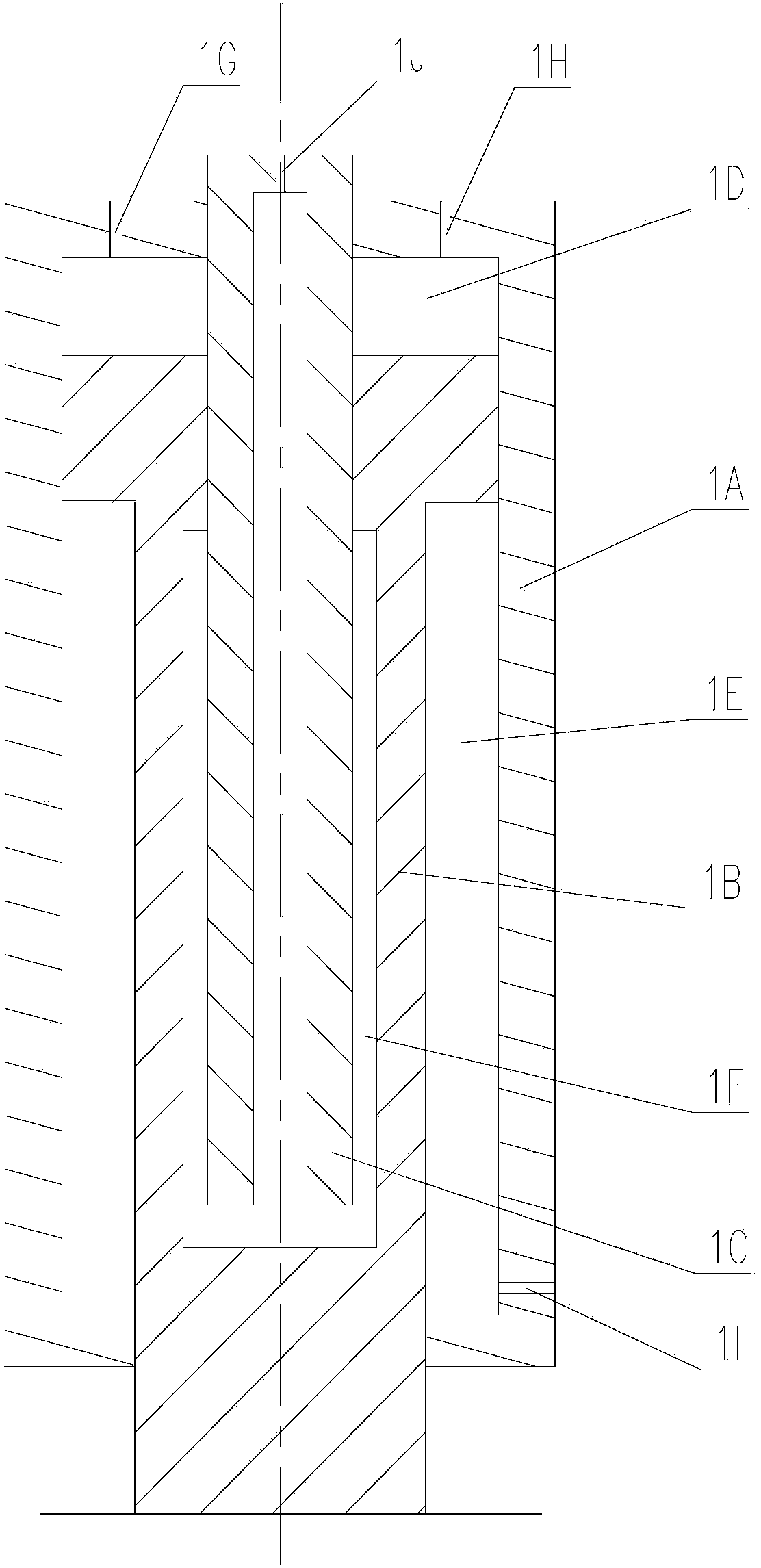

[0032] like figure 2 As shown, the structure of the first hydraulic cylinder N1 and the second hydraulic cylinder N2 is exactly the same, and each is composed of a cylinder body 1A, a piston 1B, and a fixed plunger 1C, and the cylinder body 1A, the piston 1B, and the fixed plunger 1C are respectively A cylindrical rotating body with a cylindrical inner cavity, the central axis of the three is coaxial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com