Hot-wind oxygen-rich experiment device utilizing sintering annular cooler

A technology of sintering ring cooler and experimental device, which is applied in the field of sintering, can solve the problems of not fully utilizing the heat source of the iron and steel plant, and the accuracy of sintering experiments is limited, so as to achieve the effect of reducing energy consumption and improving temperature accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

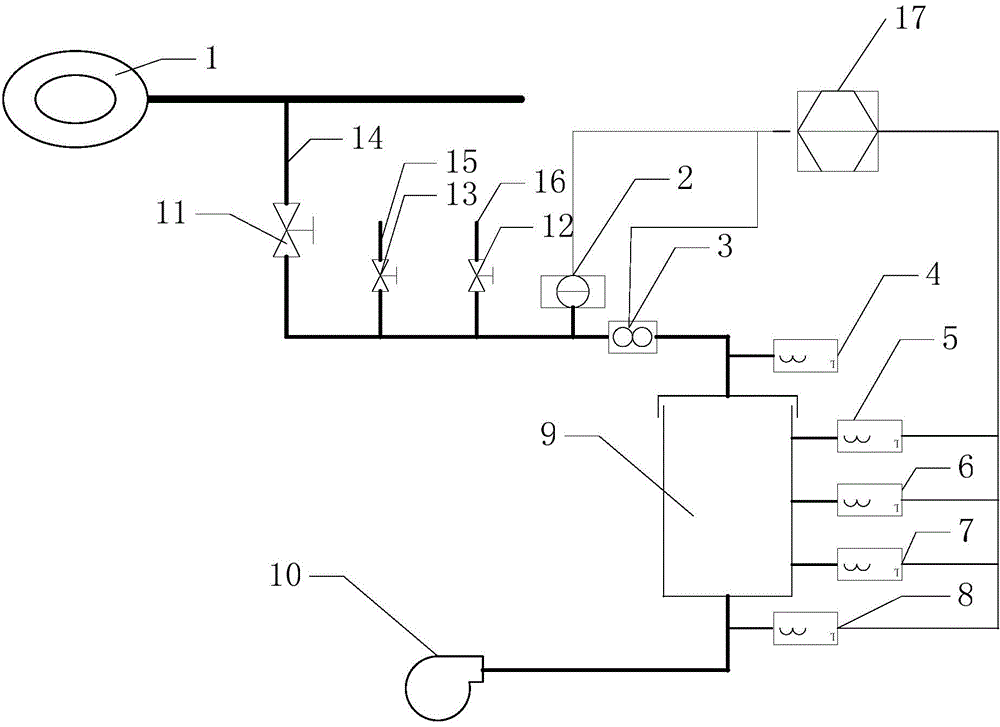

[0013] Such as figure 1 As shown, the embodiment of the present invention includes a sintering ring cooler 1, an oxygen concentration meter 2, a flow meter 3, a hot air thermometer 4, an upper thermometer 5, a middle thermometer 6, a lower thermometer 7, an exhaust gas thermometer 8, a sintering cup 9, and an exhaust fan 10 , valve 11, valve 12, valve 13, hot air pipeline 14, natural air pipeline 15, oxygen pipeline 16, computer 17.

[0014] Specifically, a hot air pipeline 14 is connected between the sintering ring cooler 1 for providing hot air and the sintering cup 9 used for the sintering experiment, and the exhaust fan 10 is connected to the exhaust gas pipeline of the sintering cup 9, so that the sintering ring cooler The hot blast in 1 is introduced in the sintering cup 9. On the hot blast pipeline 14, a valve 11 is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap