The wiring structure of the glue-injected package wire cap and the wiring process of the on-site glue-injected package wire cap

A technology of plastic injection packaging and wire caps, which is applied in the direction of cable connection/termination equipment, cable terminals, etc., can solve the problems of line insulation drop, wire joint corrosion, and complicated process, so as to reduce failures, prevent corrosion, The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

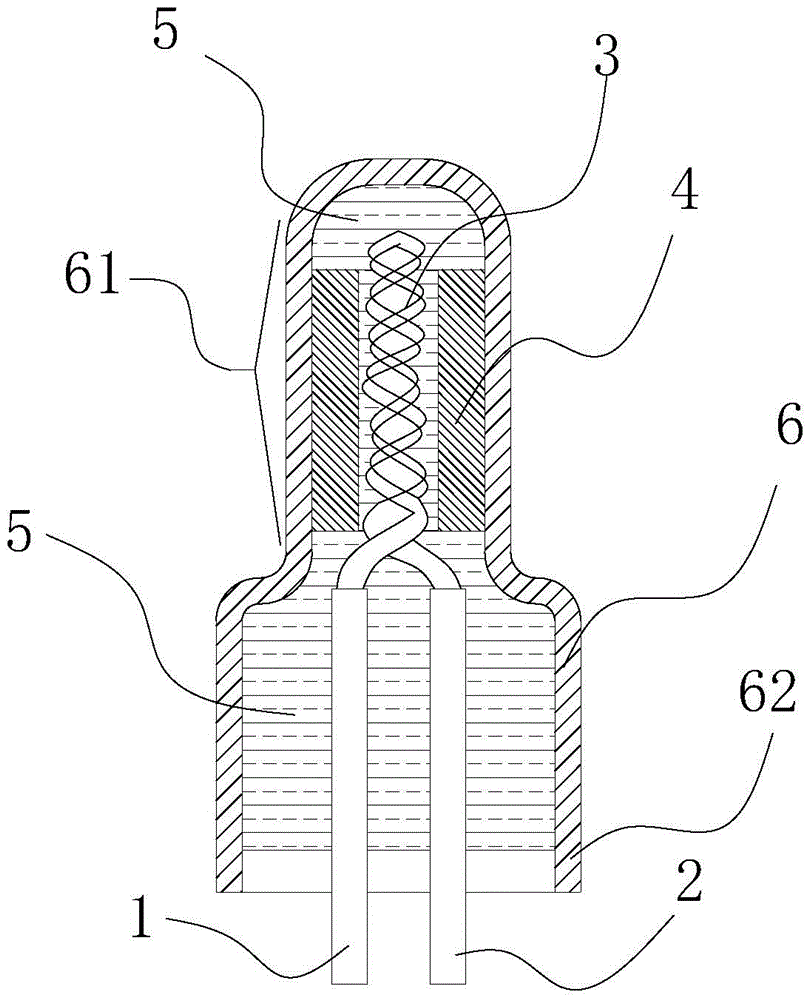

[0046] The wire cap 6 and the wire cap 6 made of PA66 have an insulation rating of ≥500V; the adaptable temperature is -40°C to 200°C, and the flame retardant grade is UL94-V0. Using the above-mentioned wire cap 6 to carry out on-site glue injection packaging wire cap wiring process includes the following steps:

[0047] A. First, peel off 13mm of the insulating sheath at the end of the A wire 1 that needs to be connected and the insulation sheath at the end of the B wire 2 that needs to be connected;

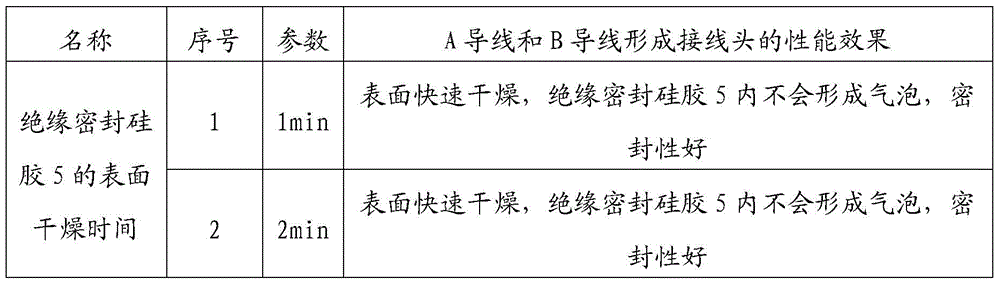

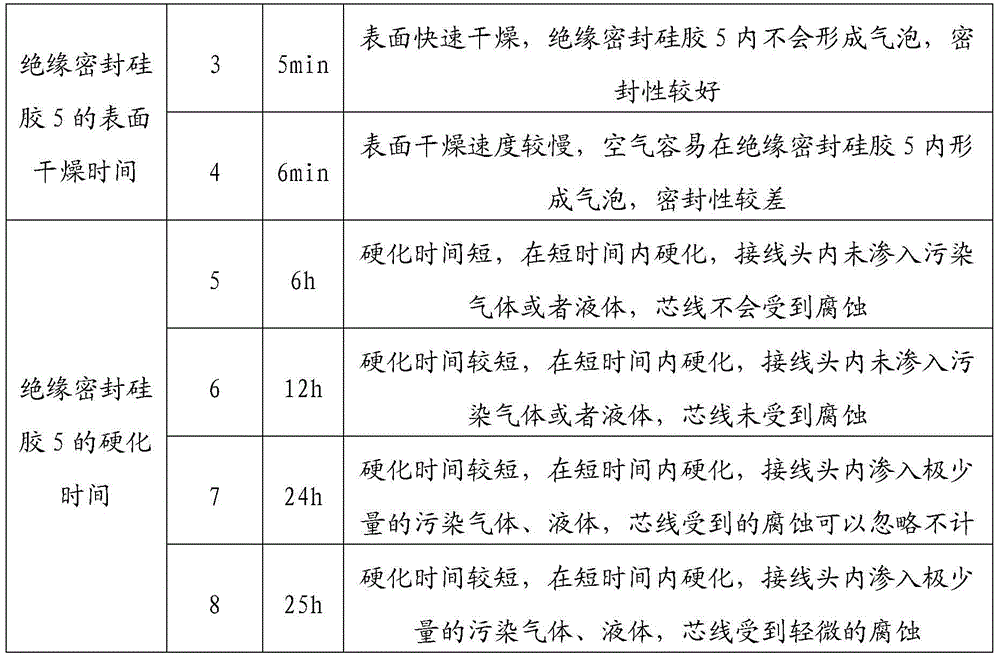

[0048] B. Put the wire core of the A wire 1 stripped of the insulation sheath and the wire core of the B wire 2 stripped of the insulation sheath together, so that they are twisted together to form a core wire 3; Inject the insulating sealing silica gel 5 into the wire cap 6 , until the insulating and sealing silica gel 5 fills the inner cavity between the inner crimping sleeve 4 of the wire cap 6 and the blind end section 61 of the wire cap 6, stop the glue injection;

[0049...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com