Cable outer sheath thermal shrinkage patching method

A technology for outer sheath and cable, which is applied in the field of cable outer sheath thermal shrinkage repair method, which can solve the problem that the cable insulation tape and the outer sheath are easy to enter water and moisture, the cable insulation tape cannot be in close contact with the outer sheath layer, and the cable Problems such as poor strength of the insulating tape are achieved to solve the effects of incomplete maintenance, good fixing effect and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 15 damaged parts of the outer sheath of the 220kV Yuancang first-line cable of the Shijiazhuang Power Supply Company in Hebei Province are maintained by adopting the thermal shrinkage repair method of the outer sheath of the present invention.

[0035] Specific steps are as follows:

[0036] Step 1: Use a glass sheet to scrape off the graphite layer at the damaged part of the cable outer sheath, specifically, the damaged part of the outer sheath is the center of the circle, and the scraping radius is 10cm;

[0037] Step 2: Use J-20 insulating self-adhesive tape to wrap and seal the section of the damaged part of the cable. The winding method is: wrap the insulating self-adhesive tape for 4 turns, and each turn of the insulating self-adhesive tape is self-adhesive to the previous round of insulating self-adhesive tape. Half of the belt is overlapped, and the winding range covers the scraped graphite layer;

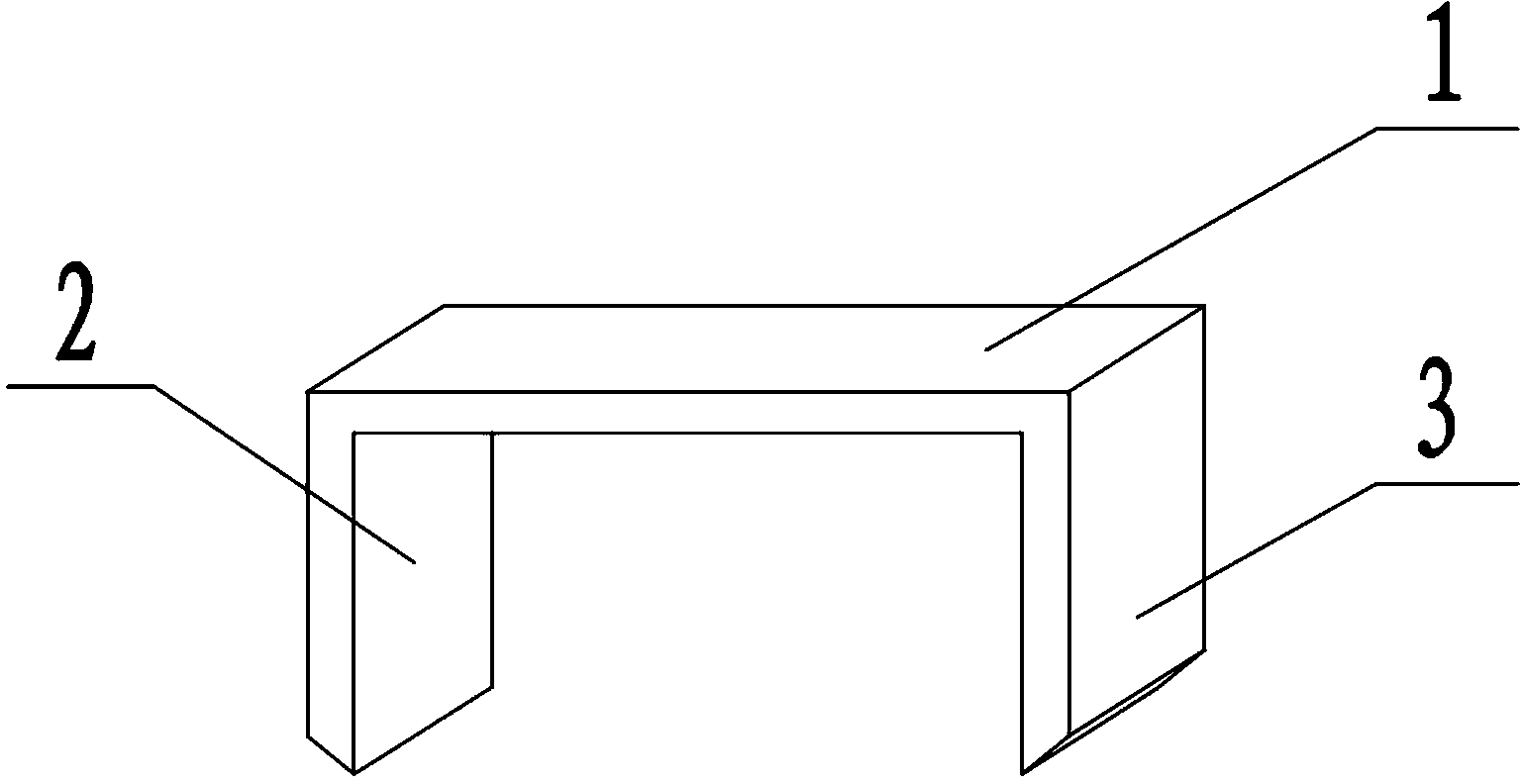

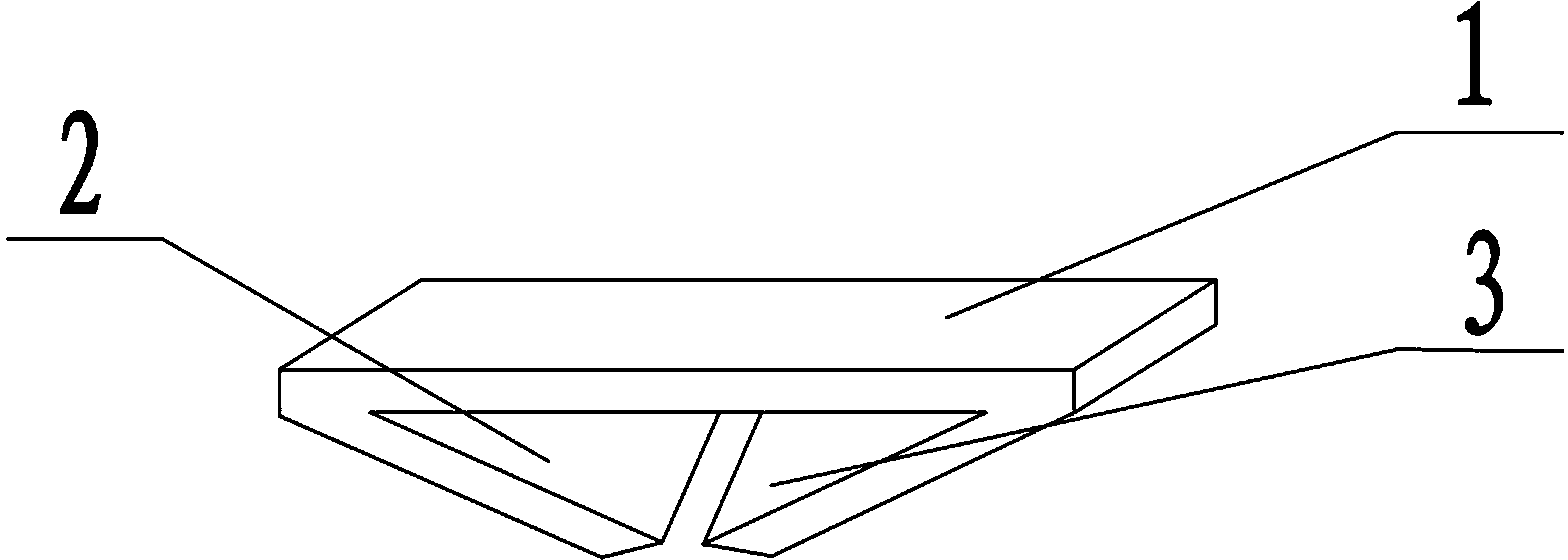

[0038] Step 3: Cover the part where the insulating self-adhesi...

Embodiment 2

[0041] 8 damaged parts of the outer sheath of the 220kV Yuancang first-line cable of Shijiazhuang Power Supply Company in Hebei Province are maintained by adopting the thermal shrinkage repair method of the outer sheath of the present invention.

[0042] Specific steps are as follows:

[0043] Step 1: Use a glass sheet to scrape off the graphite layer at the damaged part of the cable outer sheath, specifically, the damaged part of the outer sheath is the center of the circle, and the scraping radius is 20cm;

[0044] Step 2: Use J-20 insulating self-adhesive tape to wrap and seal the section of the damaged part of the cable. The winding method is: wrap the insulating self-adhesive tape 5 times, and each turn of the insulating self-adhesive tape is insulated and self-adhesive to the previous circle. Half of the belt is overlapped, and the winding range covers the scraped graphite layer;

[0045] Step 3: Wrap the protective sheet made of PET heat-shrinkable material on the cabl...

Embodiment 3

[0048] Nine damaged parts of the outer sheath of the 220kV Yuancang No. 2 cable of the Shijiazhuang Power Supply Company in Hebei Province are maintained by adopting the thermal shrinkage repair method of the outer sheath of the present invention.

[0049] Specific steps are as follows:

[0050] Step 1: Use a glass sheet to scrape off the graphite layer at the damaged part of the cable outer sheath, specifically, the damaged part of the outer sheath is the center of the circle, and the scraping radius is 15cm;

[0051] Step 2: Use J-20 insulating self-adhesive tape to wrap and seal the section of the damaged part of the cable. The winding method is: wrap the insulating self-adhesive tape for 6 turns, and each turn of the insulating self-adhesive tape is bonded to the previous turn of insulating self-adhesive tape. Half of the belt is overlapped, and the winding range covers the scraped graphite layer;

[0052] Step 3: Wrap the protective sheet made of PET heat-shrinkable mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com