High power density motor with water cooling structure

A high power density, water cooling technology, applied in the electrical field, can solve the problems of temperature rise and unbalanced temperature distribution, and achieve the effect of improving stability, simple structure and reducing working temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

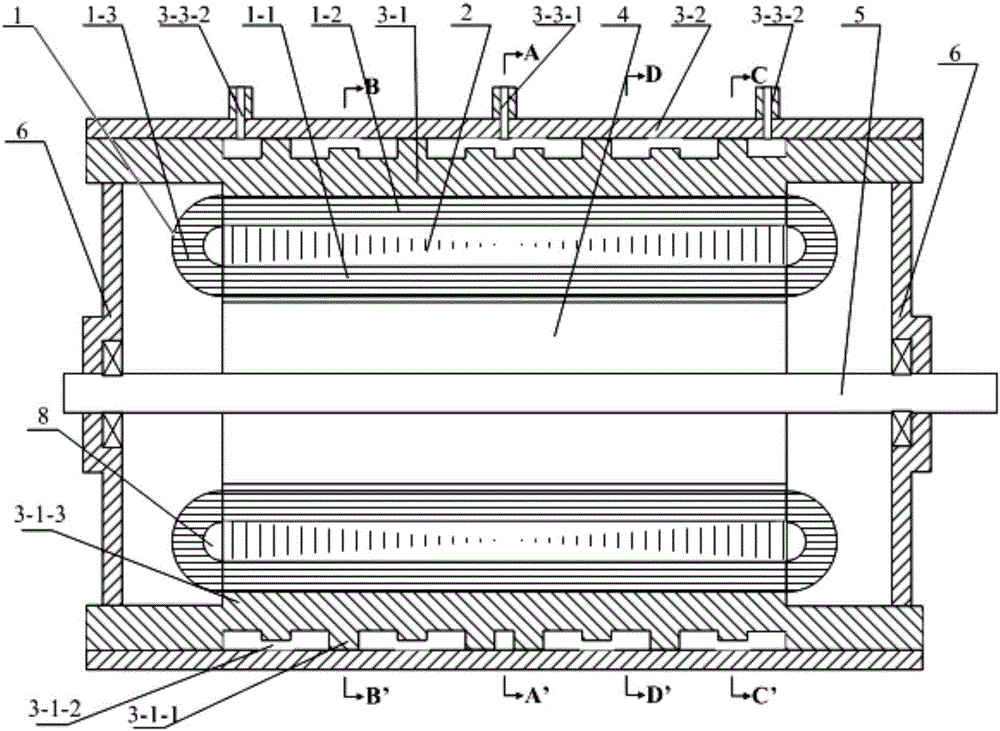

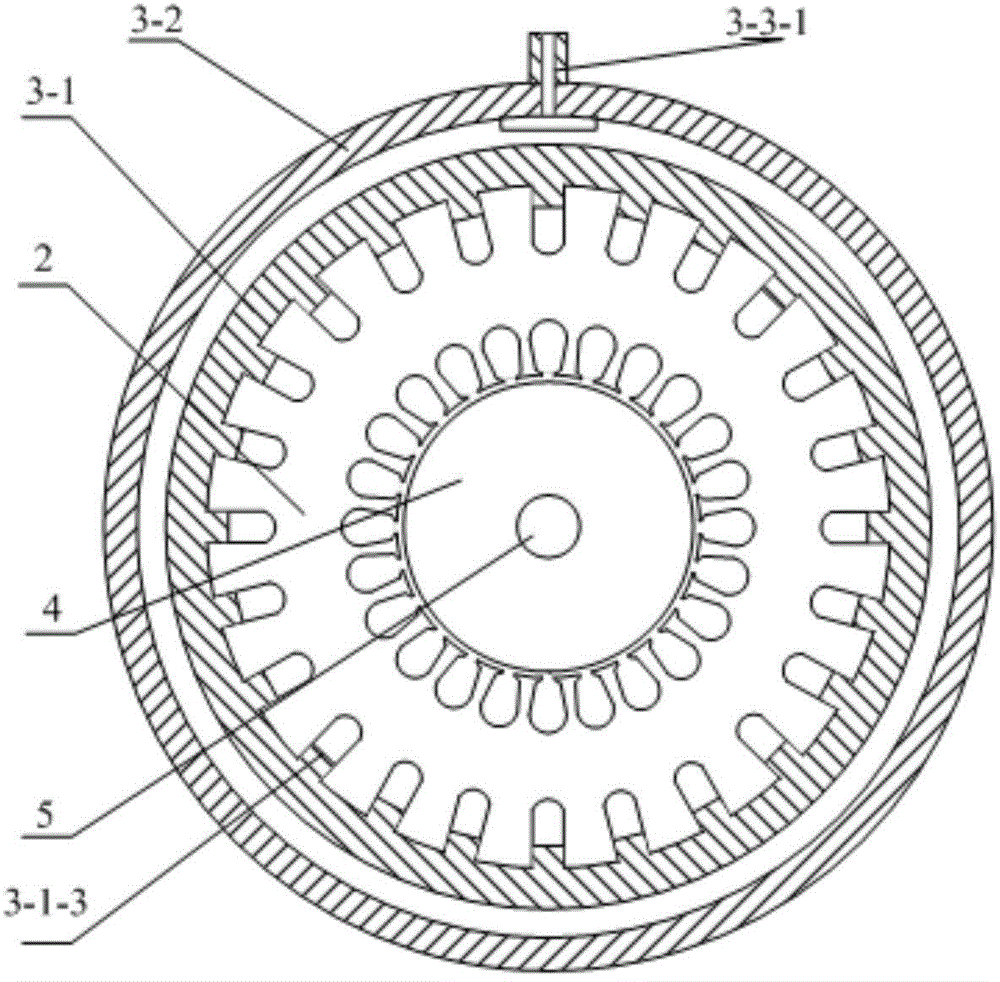

[0042] The embodiments of the present invention will be further described with reference to the accompanying drawings:

[0043] Such as Figure 1-Figure 9 As shown, a high-power-density motor with a water-cooled structure includes: stator winding 1, stator core 2, casing, rotor 4, rotating shaft 5, end cover 6 and bearings;

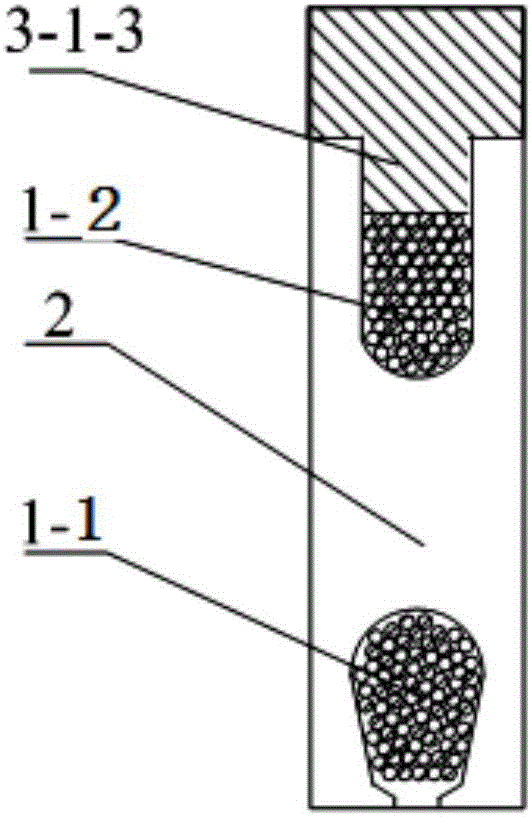

[0044] An inner slot 2-1 and an outer slot 2-2 are evenly distributed along the circumference on the inner and outer circles of the stator core 2;

[0045] The number of inner grooves 2-1 and outer grooves 2-2 on the stator core 2 are equal, and the corresponding inner grooves 2-1 and outer grooves 2-2 are at the same radius;

[0046] The cross-sectional area of the outer tank 2-2 is greater than 30%-50% of the cross-sectional area of the inner tank 2-1;

[0047] The stator winding 1 is looped on the stator core 2 in a back-winding manner. The inner winding 1-1 is placed in the inner slot 2-1 on the stator core 2, and the outer winding 1-2 is placed in the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com