Translation type rotary compressing device

A rotary compression and translation technology, applied in rotary piston pumps, rotary piston machinery, rotary piston engines, etc., can solve the problem that the compression heat and friction heat of the machine cannot be quickly discharged, the cylinder is bulky, and the heat dissipation performance is poor. and other problems, to achieve the effect of improving heat dissipation effect and compression efficiency, simplifying processing technology and improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

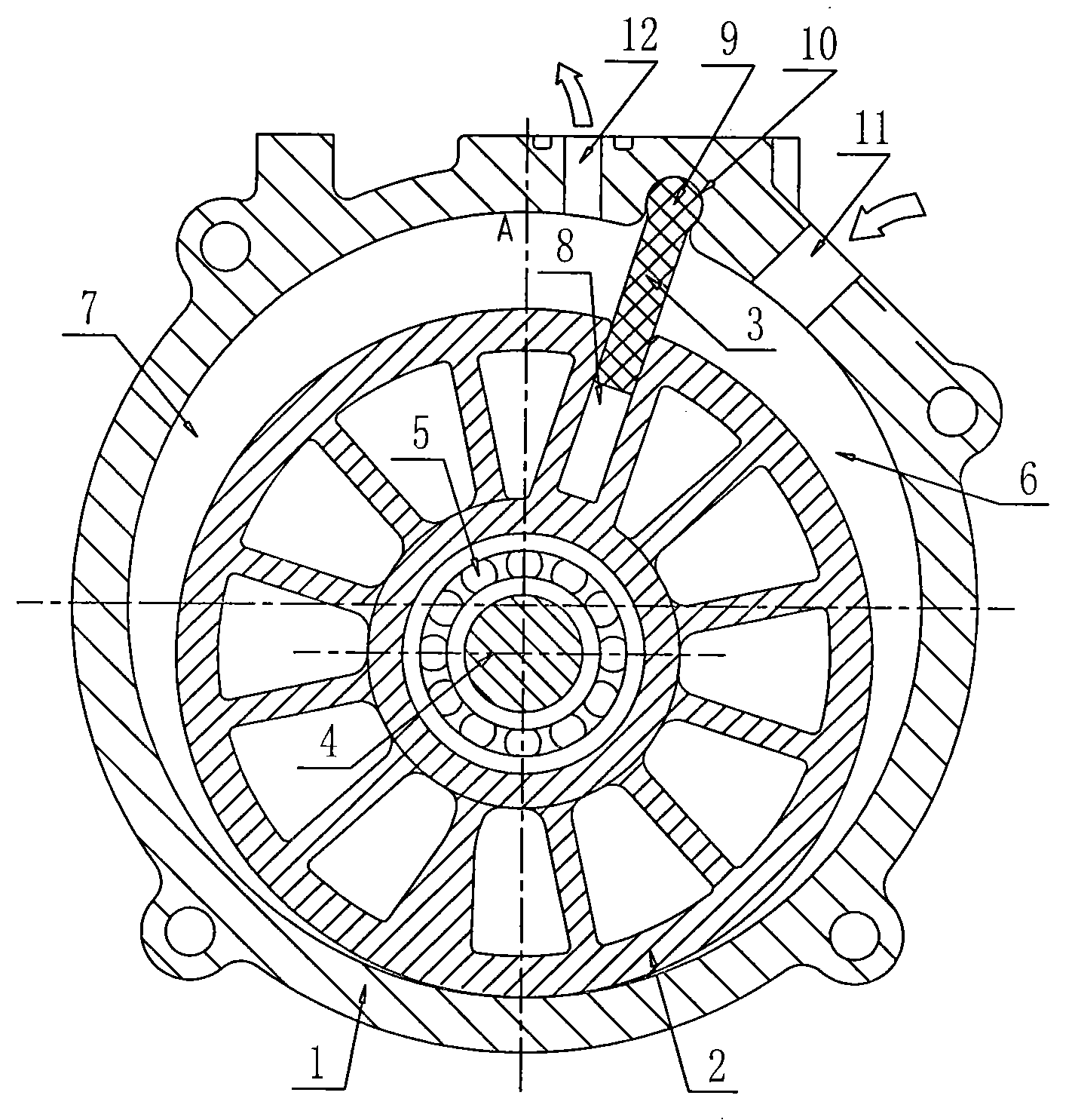

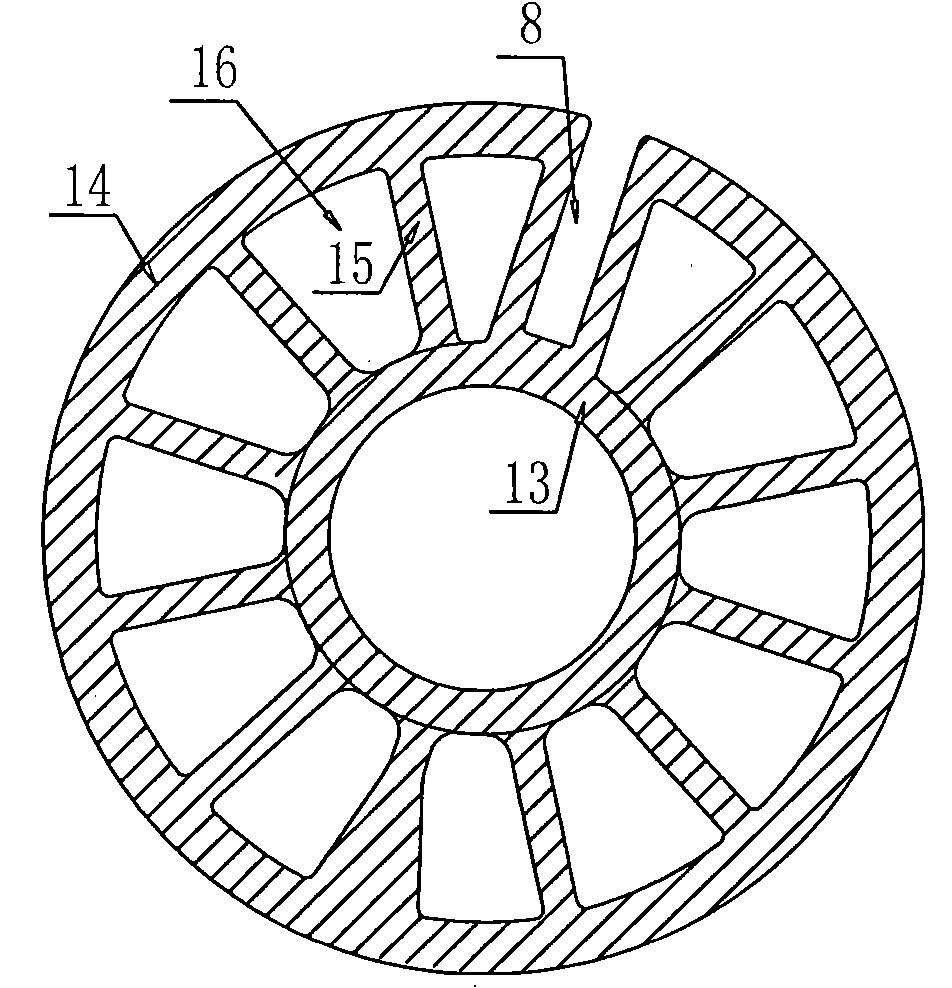

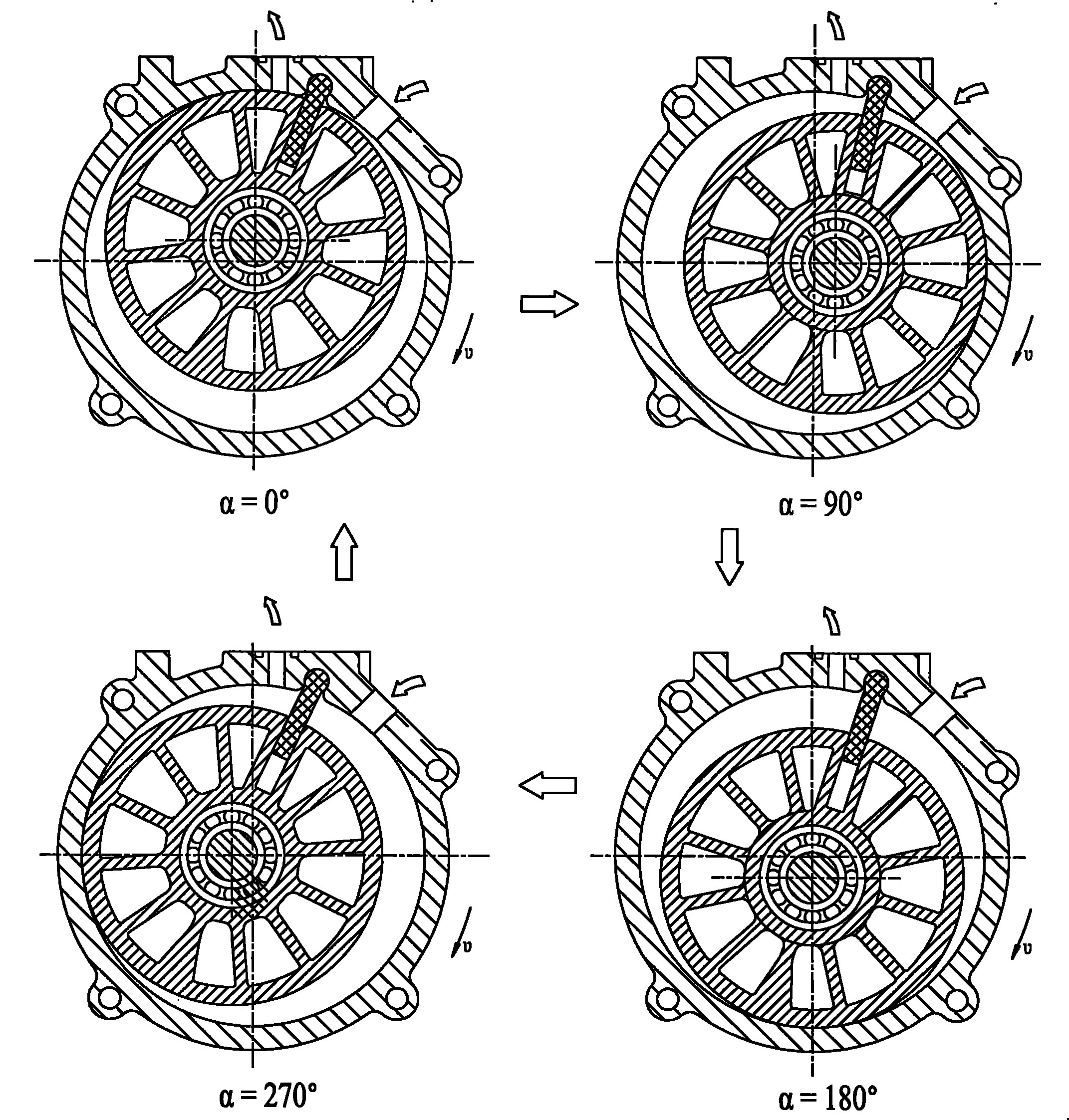

[0025] Such as figure 1 The translational rotary compression device shown includes a cylinder body 1 , a translational piston 2 , an eccentric rotor 4 , a bearing 5 and a slide plate 6 . Wherein, the circular cylinder body 1 is fixed, and the outer ring of the cylinder body 1 is provided with a plurality of cooling fins. The translation piston 2 is arranged in the cylinder body 1, and the translation piston 2 is arranged on the eccentric rotor 4 and arranged eccentrically with the large through hole of the cylinder body 1. The rotation center of the rotor 4 is concentric with the cylinder body 1, and the outer surface of the translation piston 2 is kept tangent to the inner surface of the circular cylinder body 1, forming crescent-shaped working chambers 6, 7, and the translation piston 2 can circle the cylinder body 1's center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com