Belt and support for rotor mechanism in rotary apparatus and rotary apparatus comprising the same

A technology of rotating equipment and rotors, applied in the field of compressors or engines, belts and supports, and pistonless rotary pumps, which can solve problems such as damage and energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

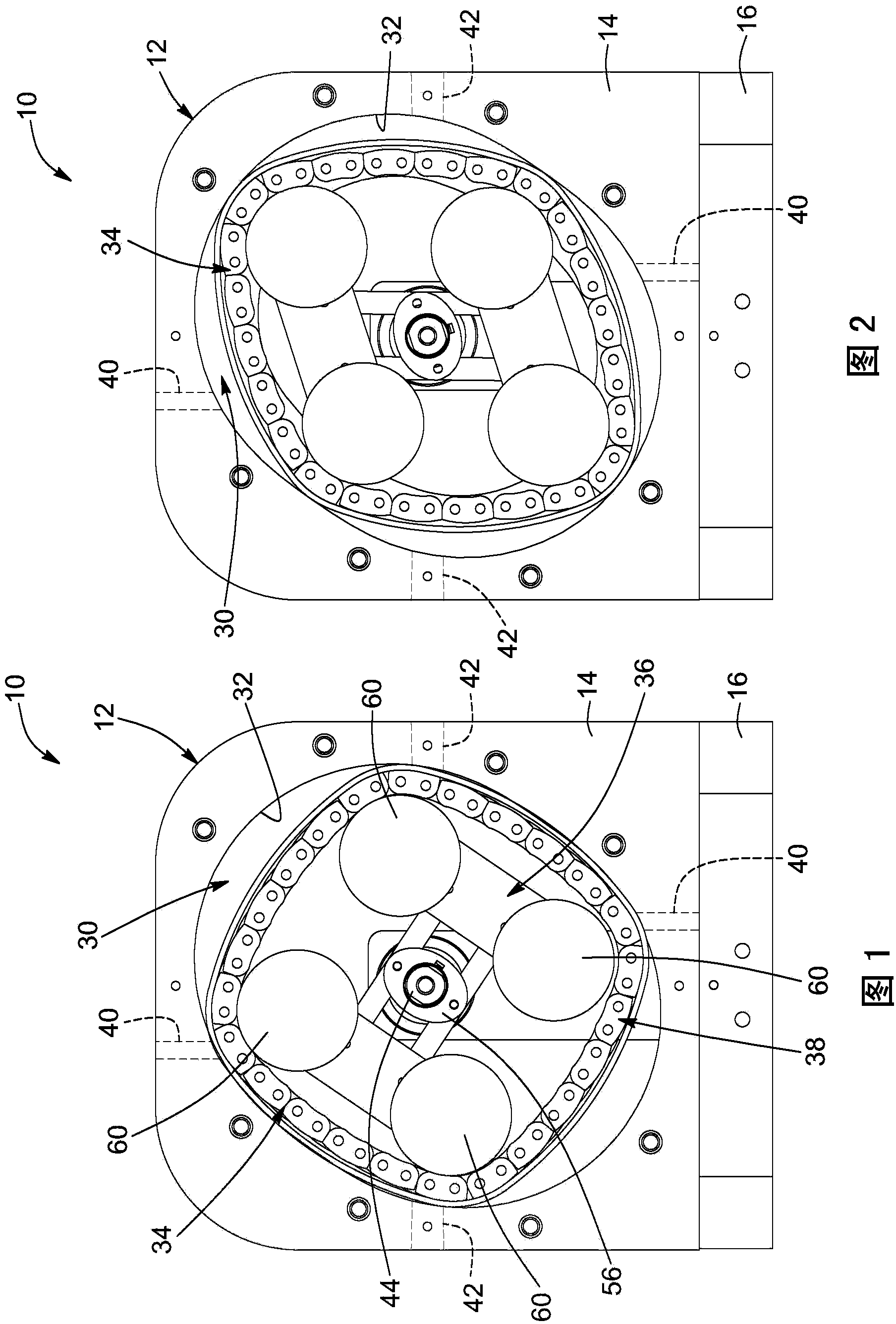

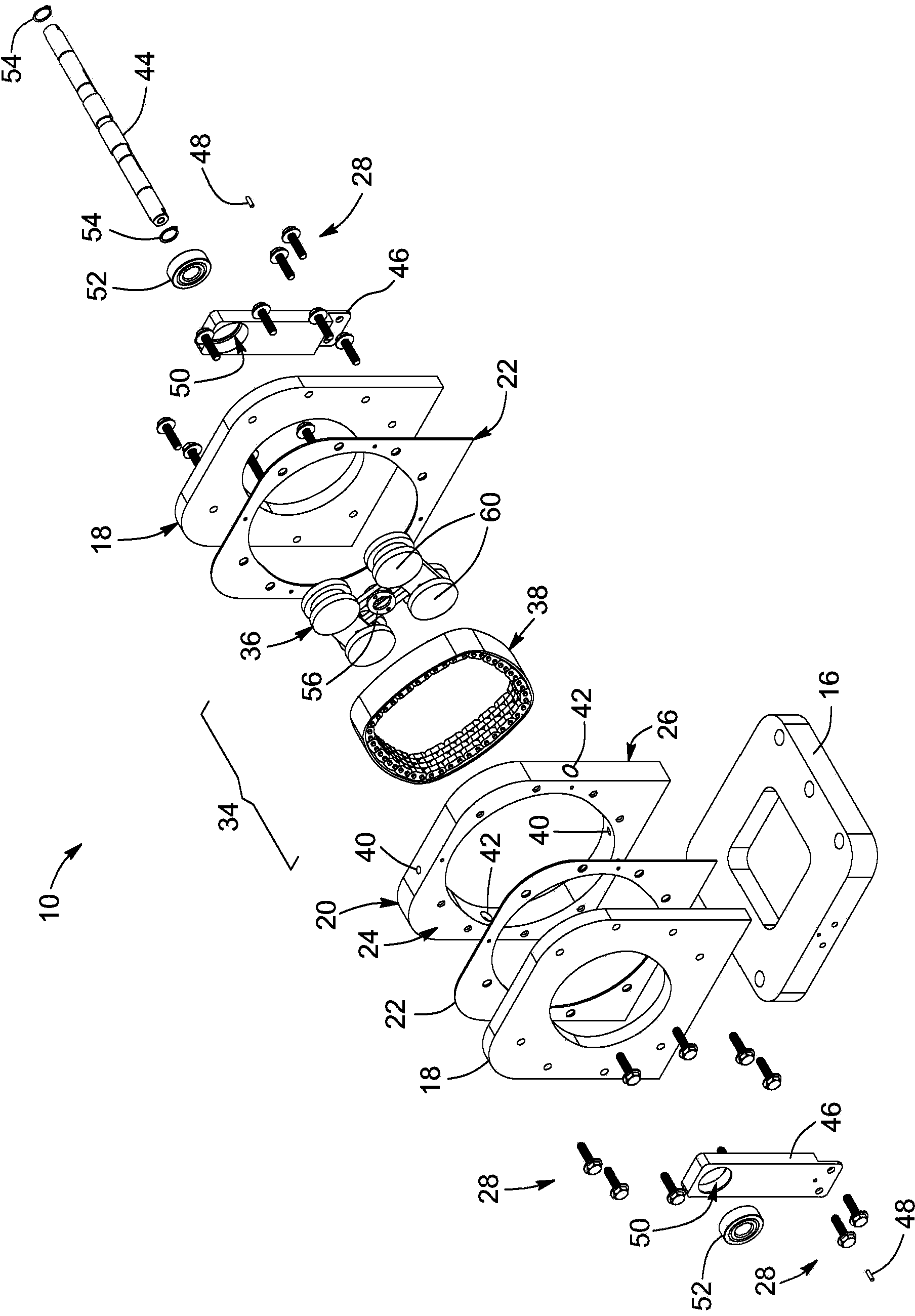

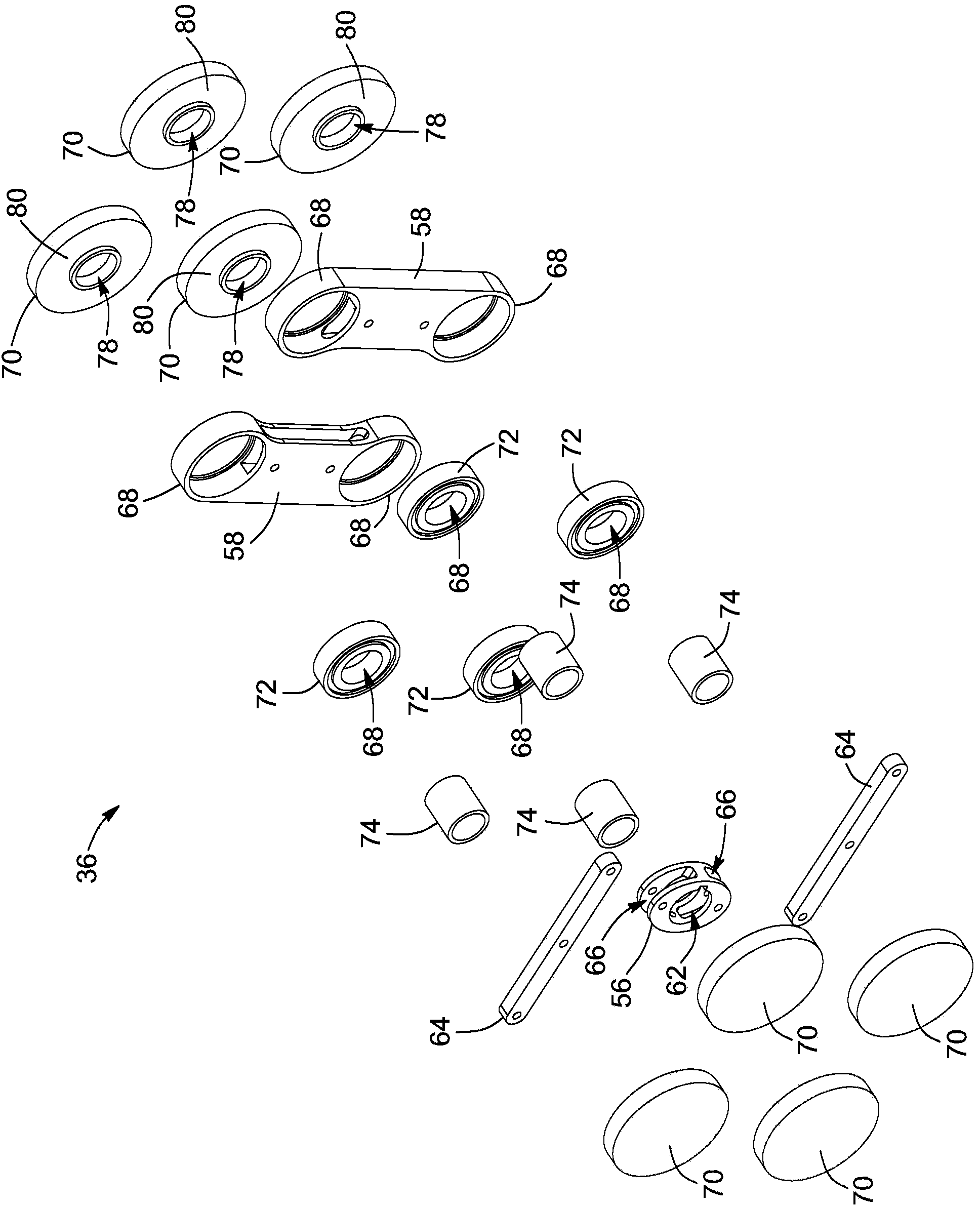

[0073] In general, a rotary device is provided that includes a housing having an inner contoured wall defining an inner fluid chamber. A rotor mechanism is positioned within the chamber and configured to rotate therein. The rotor mechanism includes a belt and a rotatable rotor assembly. The belt is a closed loop belt and is mounted to the rotor assembly. The rotor assembly is a rotatable rigid structure that supports and changes the shape of the outer perimeter of the belt. The motion imparting assembly imparts rotational motion to the rotor assembly. The band engages a portion of the inner profile wall during rotation of the rotor assembly. The housing also includes an inlet port and an outlet port in fluid communication with the interior fluid chamber, providing for flow of fluid thereinto and flow of fluid therefrom. The rotary device disclosed herein may be a pump, a compressor, or an engine, which may be used in various fields.

[0074] With reference to the figures,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com