Method for fabricating lithium-ion secondary battery

A secondary battery and lithium-ion technology, applied in manufacturing tools, battery pack components, circuits, etc., can solve problems such as voltage drop, natural oxide film formation obstacles, and current limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

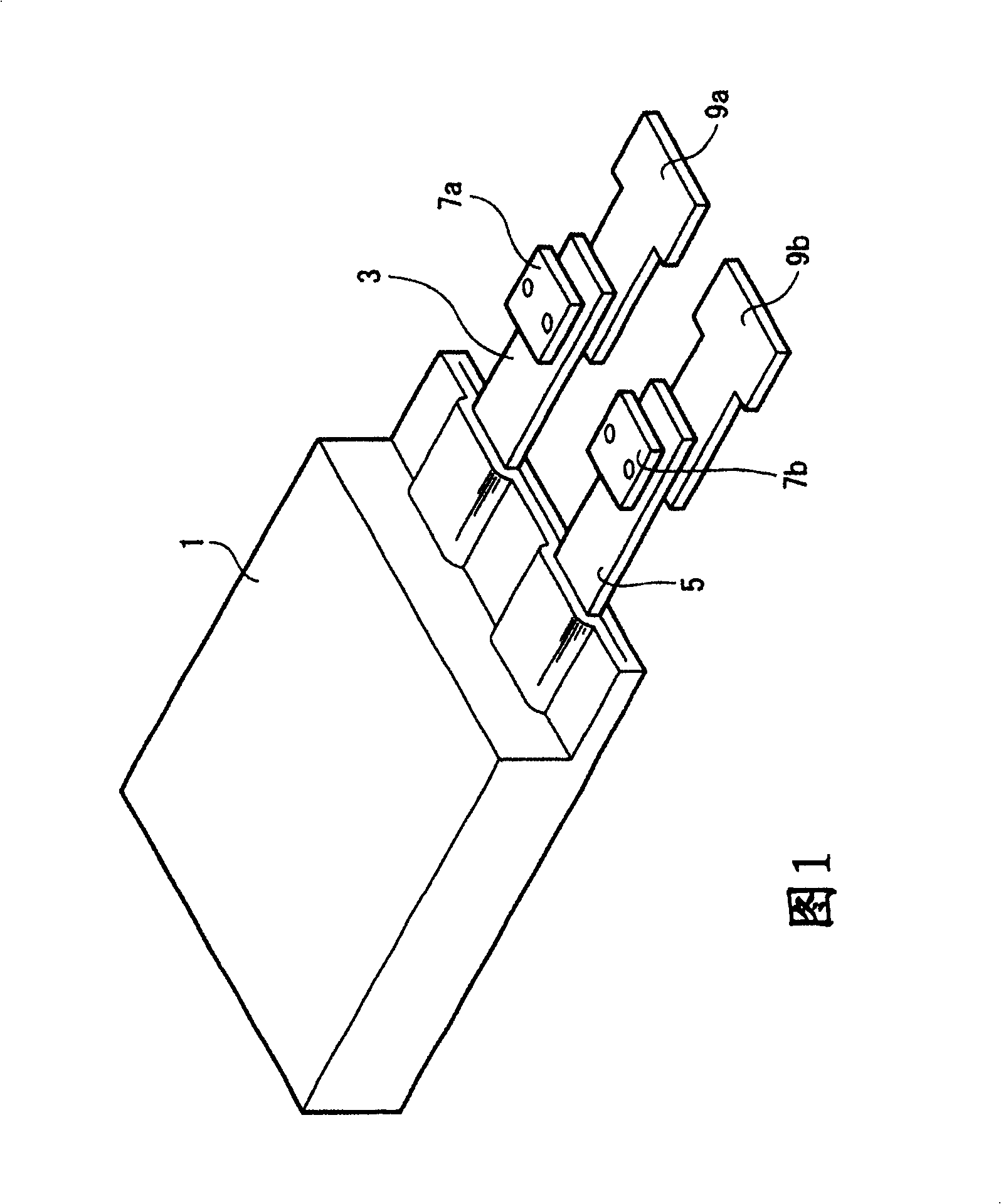

[0071] FIG. 1 shows a schematic structure of a lithium ion secondary battery according to a first embodiment of the present invention.

[0072] The lithium ion secondary battery has a main part including a secondary battery cell 1, a terminal 3 for a positive electrode, a terminal 5 for a negative electrode, an upper metal piece 7a and a lower metal piece 9a on the positive terminal, and a terminal on the negative terminal. The upper metal sheet 7b and the lower metal sheet 9b. The main part actually having these components is covered with a coating material such as aluminum lamination which is lifted away in the figure to clearly show the internal structure. In addition, for the sake of convenience, the metal pieces placed on the upper side and the lower side according to the vertical direction of the figure are referred to herein as upper metal pieces 7a and 7b and lower metal pieces 9a and 9b respectively, needless to say, the vertical relationship can be reversed , as lon...

no. 2 example

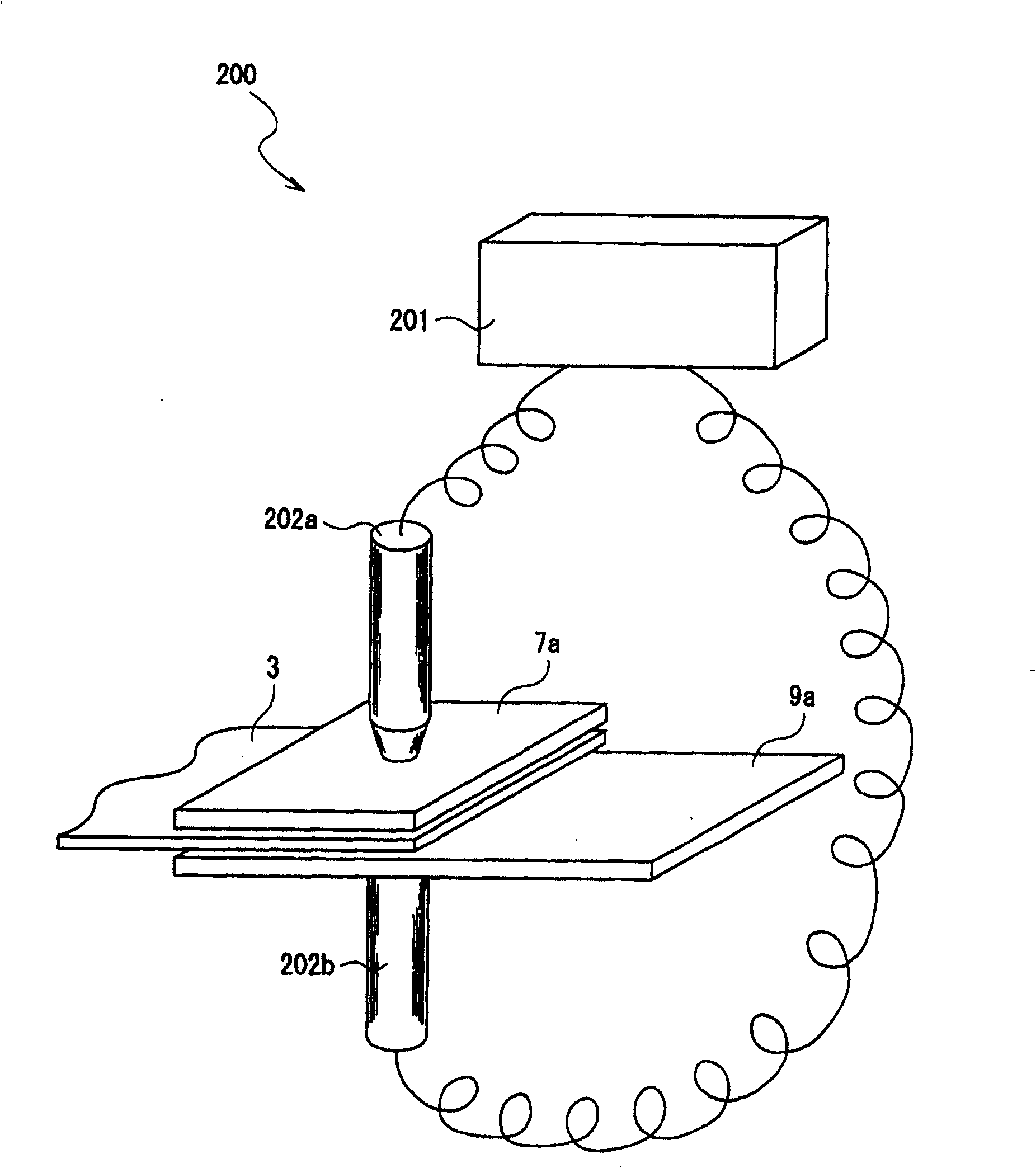

[0090] FIG. 4 shows a schematic structure of a lithium ion secondary battery according to a second embodiment of the present invention. In this embodiment, the same components as those of the first embodiment are denoted by the same reference numerals, and their descriptions are omitted or only different points are explained. The third embodiment and the following embodiments are also described in the same manner.

[0091] The lithium ion secondary battery has a main part including a secondary battery cell 1, a terminal 3 for a positive electrode, a terminal 5 for a negative electrode, a metal piece 11 on the positive terminal, and a metal piece 13 on the negative terminal. Among these parts, the secondary battery cell 1 , the terminal 3 of the positive electrode, and the terminal 5 of the negative electrode are the same as in the first embodiment.

[0092] The metal piece 11 on the positive terminal and the metal piece 13 on the negative terminal are formed by contour cuttin...

no. 3 example

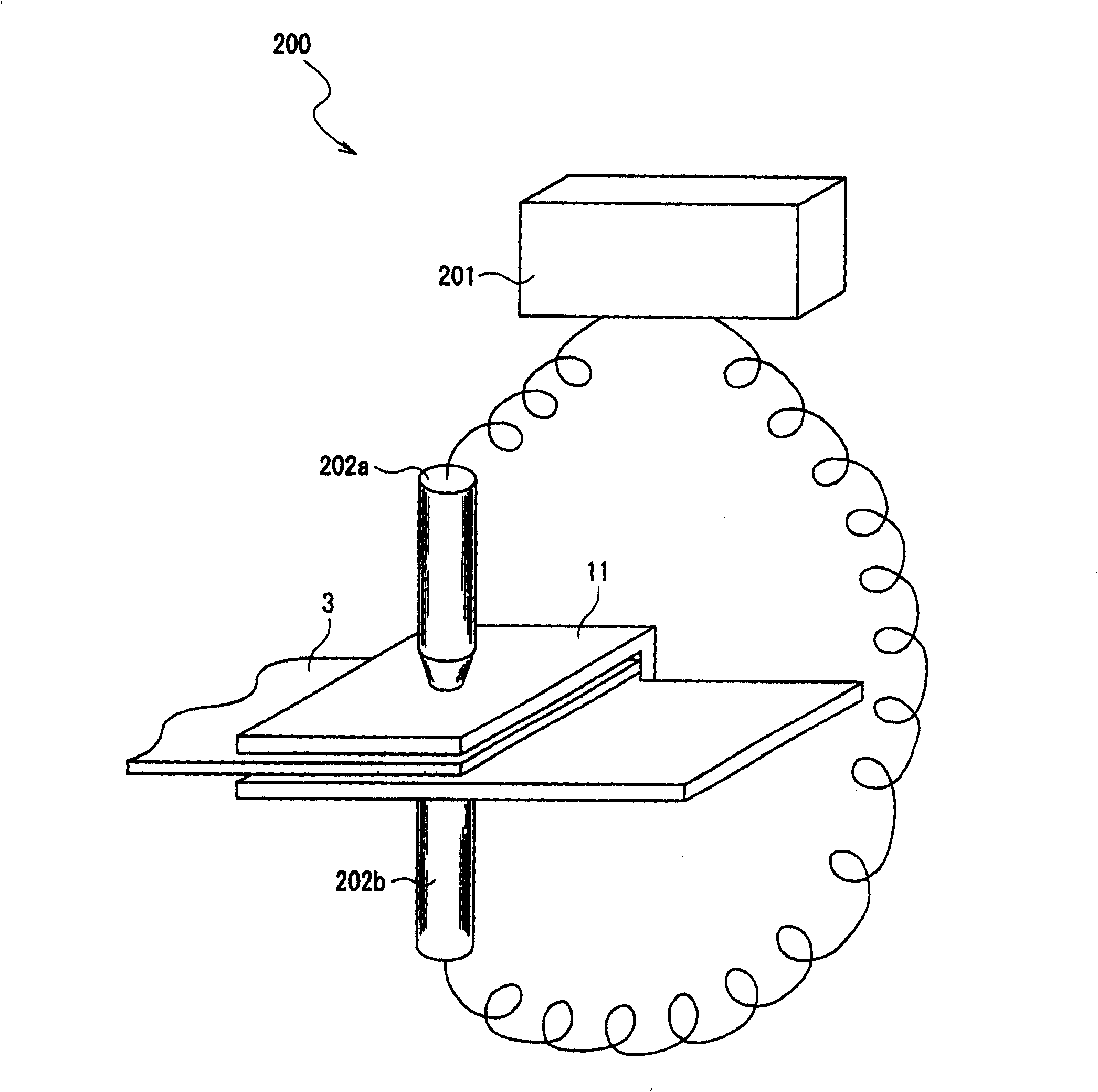

[0103] FIG. 6 shows a schematic structure of a lithium ion secondary battery according to a third embodiment of the present invention.

[0104] This lithium ion secondary battery has a main part including a secondary battery cell 1, a terminal 3 of a positive electrode having a tip portion having a slit-like cut, a terminal 5 similar to a negative electrode having a tip portion having a slit-like cut , a metal piece 15 on the positive terminal, whose tip portion is bent into a horseshoe shape and whose upper piece has a slit-like cut, and a metal piece 17 on the negative terminal, which has a tip portion similarly bent into a horseshoe shape And its upper piece has a slit-like cut.

[0105] In this lithium-ion secondary battery, in the steps of welding the terminal 3 of the positive electrode and the metal sheet 15 by a resistance welding method, and welding the terminal 5 of the negative electrode and the metal sheet 17 by a resistance welding method, it is possible to pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com