Cardan-joint shaft

A technology of cross universal joints and universal joint shafts, which is applied in the direction of couplings, elastic couplings, manufacturing tools, etc., can solve the problems of large universal joints, achieve reliable fixation, and simple manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

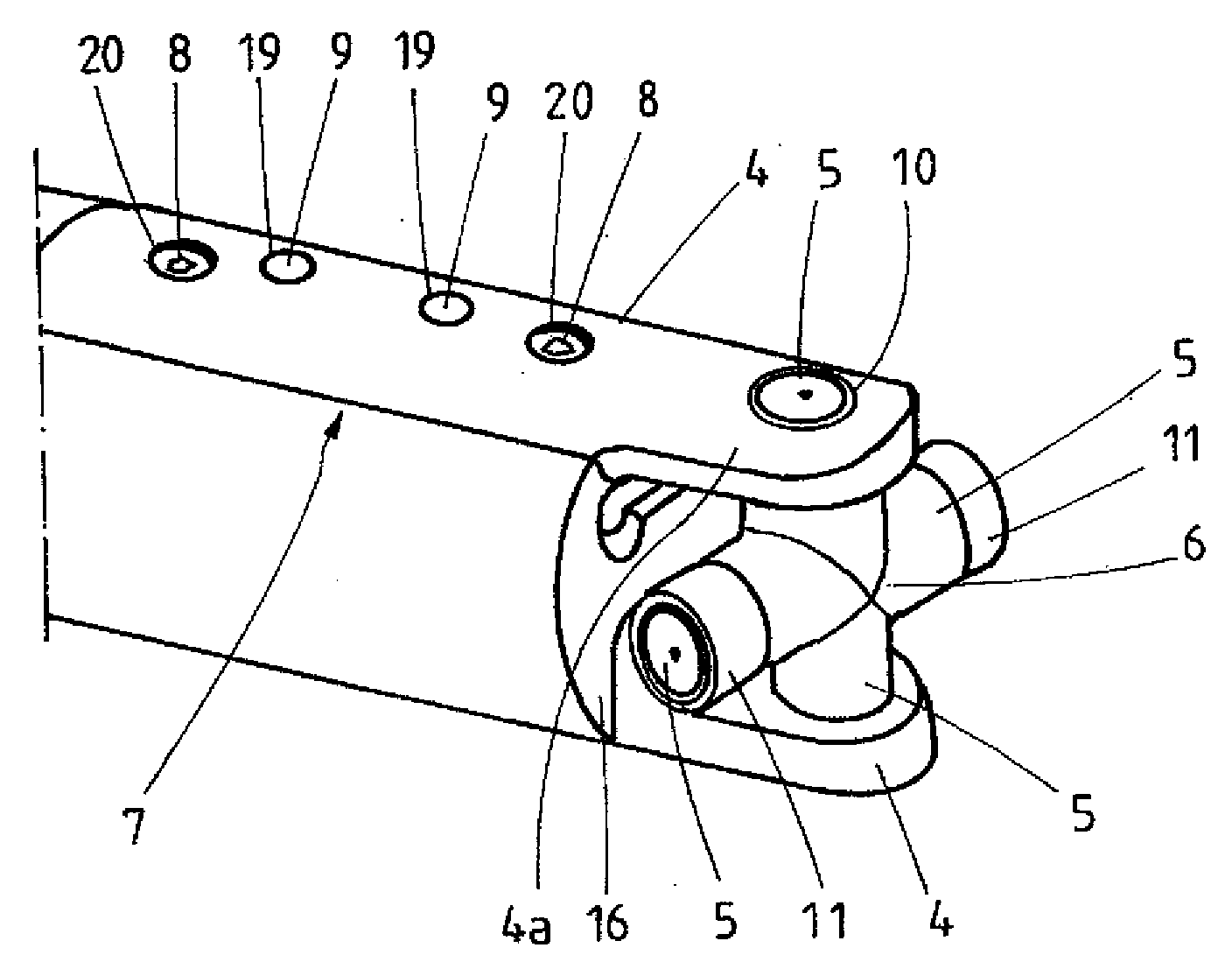

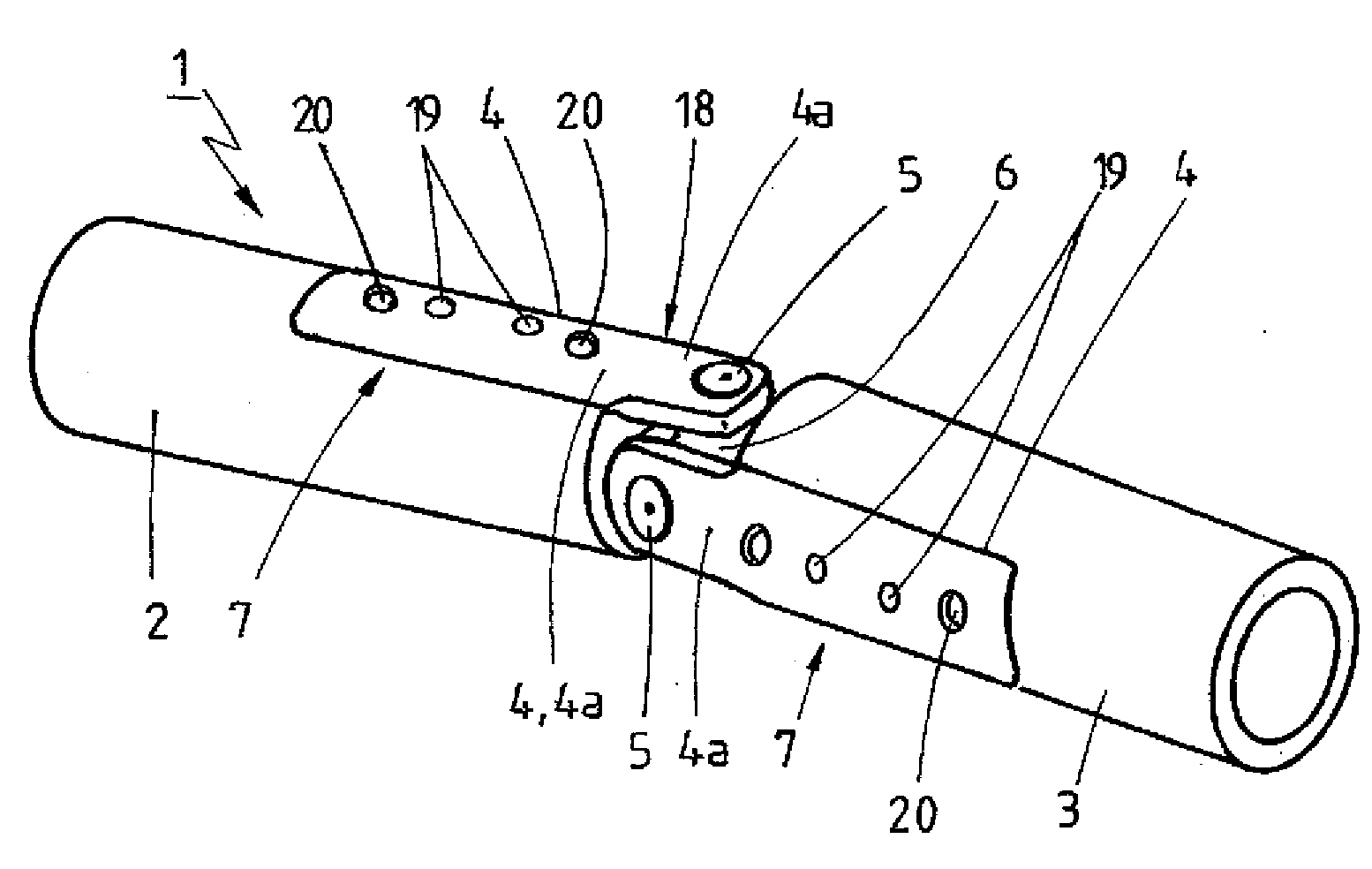

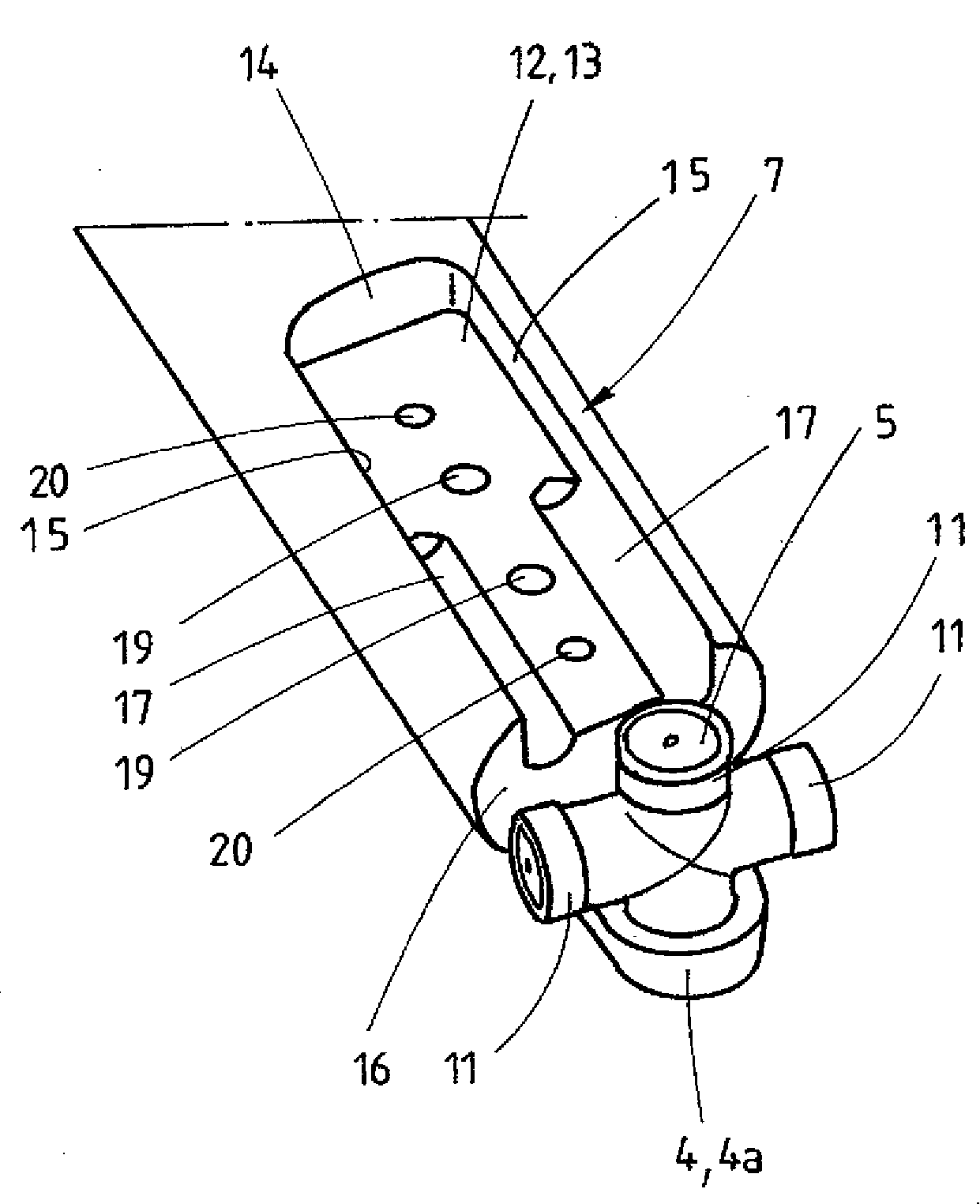

[0025] figure 1 Shows the joint area of the joint 18 with the cross joint shaft designated overall at 1 with the first joint shaft section 2 and the second joint shaft section 3. Two bearing plates 4 diametrically opposite each other are arranged thereon. The bearing plates 4 protrude beyond the respectively associated first or second cardan shaft section 2 , 3 with a protruding region 4 a at one end. The projecting regions 4 a facing each other at the first or second cardan shaft section 2 , 3 respectively jointly form a fork, between which two parts of the cardan crosshead 6 constructed in one piece are held. A shaft head 5 opposite to each other. At the respective fastening regions 7 of the joint shaft sections 2 , 3 , the bearing plates 4 are each fastened by means of cylinder-head screws 8 and fastened by means of cylindrical pins 9 . The shaft studs 5 are each held in an opening 10 , a bearing bore, which is formed in the projecting region 4 a of the bearing plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com