Ladle buggy under converter and application of ladle buggy

A technology for ladle cars and converters, which is applied in the manufacture of converters, casting molten material containers, manufacturing tools, etc. It can solve the problems of long time for replacing slag pots, high labor intensity of workers, safety of slag pot overflowing, etc., and avoid cleaning steel Chartered vehicles accumulate slag, save time for replacing the slag basin, and facilitate cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

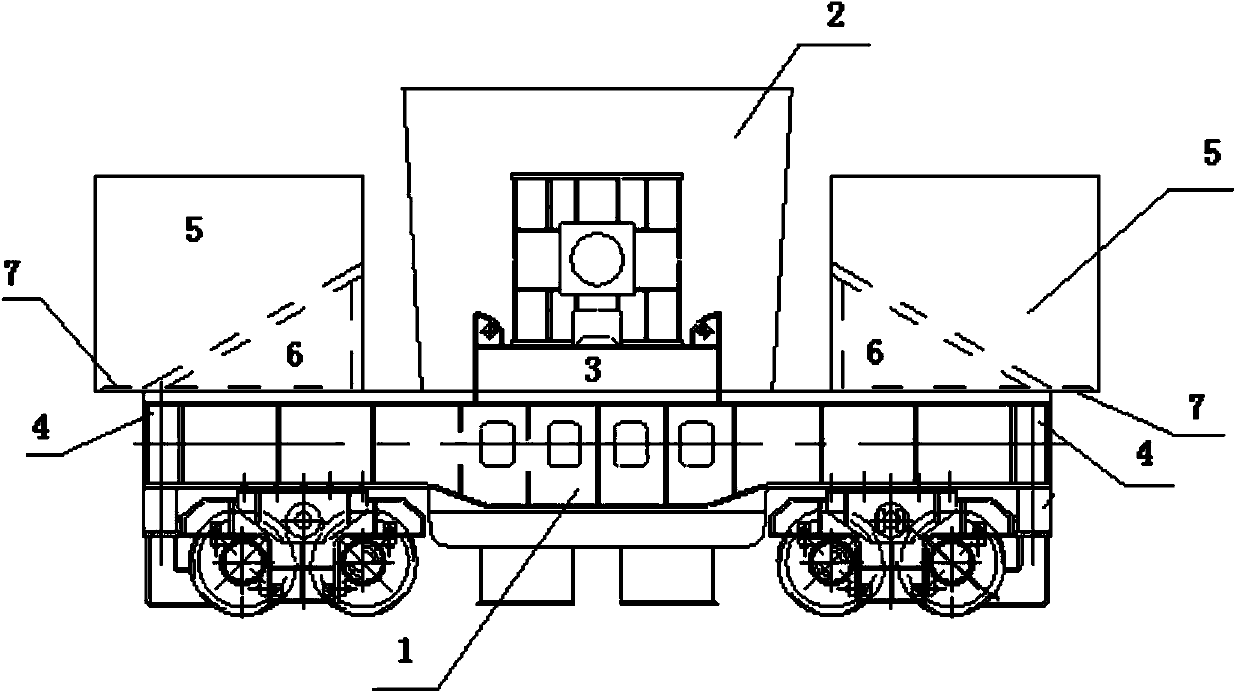

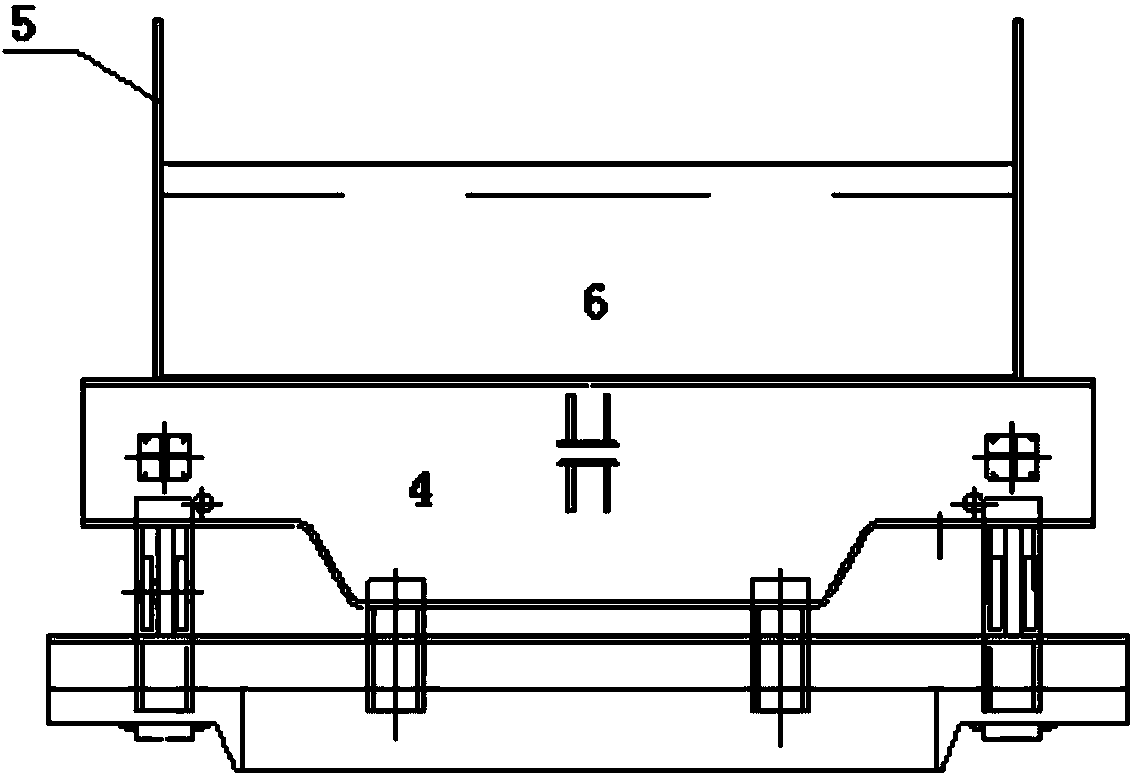

[0033] figure 1 , 2 shown.

[0034] A ladle car under a converter furnace, comprising a car body 1 and a ladle 2; the car body includes a ladle car seat frame 3 located under the ladle, and slag basin shelf frames 4 located on both sides of the steel ladle 2; Splash guards 5 are installed on both sides of the frame 4, and an inclined slag discharge channel 6 is arranged between the oppositely arranged splash guards 5. In the inclined slag discharge channel 6, the end far away from the ladle 2 is lower than the end close to the ladle 2. horizontal position.

[0035] The inclined angle of the inclined slag discharge channel 6 is 50°.

[0036] The bottom edge of the inclined slag discharge channel 6 is connected with a slag guide edge 7 protruding from the vehicle body. The slag guide edge is a steel plate or a fireproof board arranged horizontally.

[0037] The splash guard 5 is a 10cm thick steel plate.

[0038] The slag discharge channel 6 is a steel plate obliquely arra...

Embodiment 2

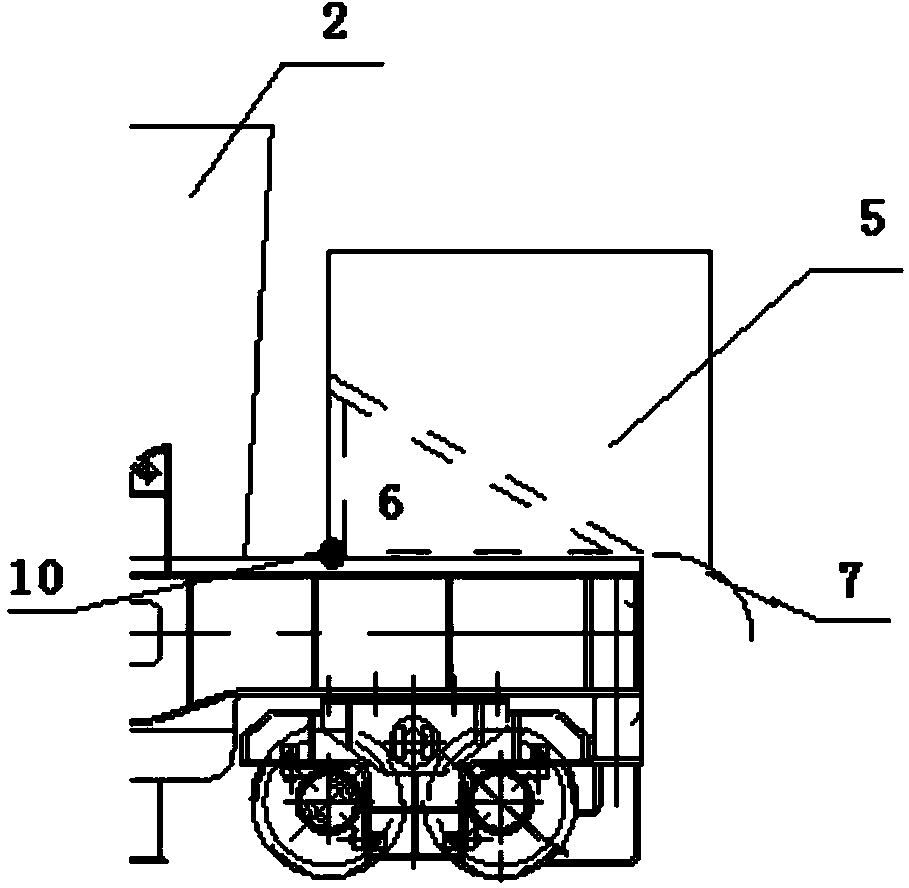

[0040] image 3 shown.

[0041] A ladle car under the converter furnace as described in Example 1, the difference is that the inclined angle of the inclined slag discharge channel 6 is 30°. The slag guiding edge 7 is an arc-shaped steel plate or a fireproof board. It ensures that the slag slides down to the bottom of the furnace smoothly, and protects the cables of the ladle car from being burned by the slag.

Embodiment 3

[0043] Such as Figure 4 , 5 shown.

[0044] A ladle car under the converter as described in Example 1, the difference is that an integral slag discharge mechanism including a splash guard 5 and an inclined slag discharge channel 6 is provided on the slag basin shelf 4; The slag discharge mechanism includes a vertical baffle 8 and a bottom plate 9 close to the ladle, and the splash baffle 5, the vertical baffle 8 and the bottom plate 9 together form a slag discharge area; the bottom plate 9 of the overall slag discharge mechanism is close to The position of the ladle 2 is provided with a rotating fixed shaft 10, and the integral slag discharge mechanism rotates along the rotating fixed shaft 10;

[0045] On both sides of the bottom of the integral slag discharge mechanism, and on the slag basin shelf 4 are respectively provided with assembly grooves 11 for placing hydraulic jacks 12, and a part of the assembly grooves 11 is exposed to the integral discharge On both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com