Numerically-controlled machine tool with fixed facing head and control method thereof

A technology of CNC machine tools and flat turntables, used in automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as difficulty, low work efficiency, and inability to directly use speed shifting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

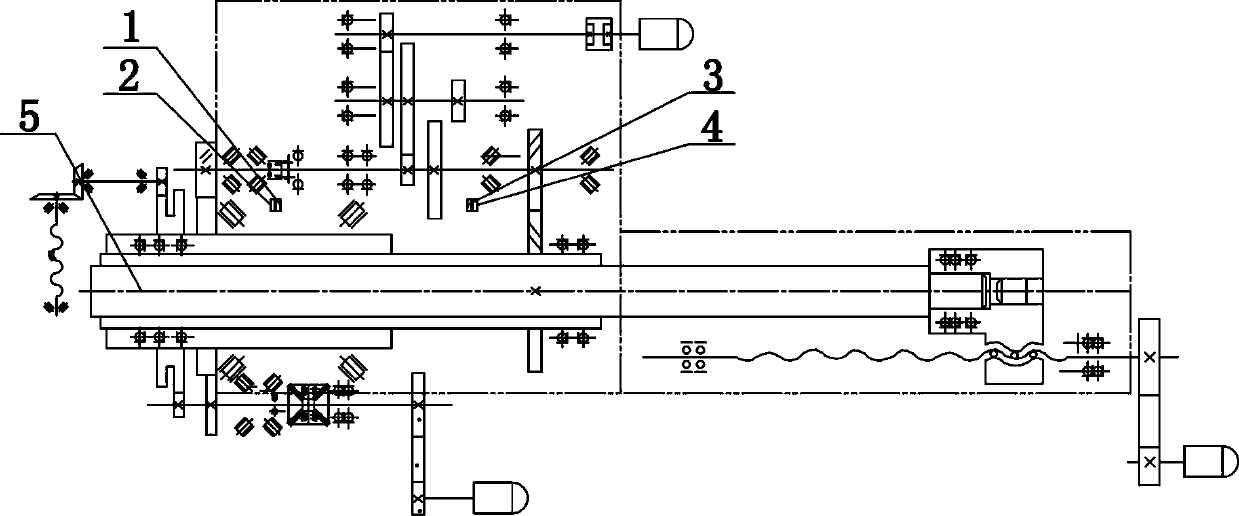

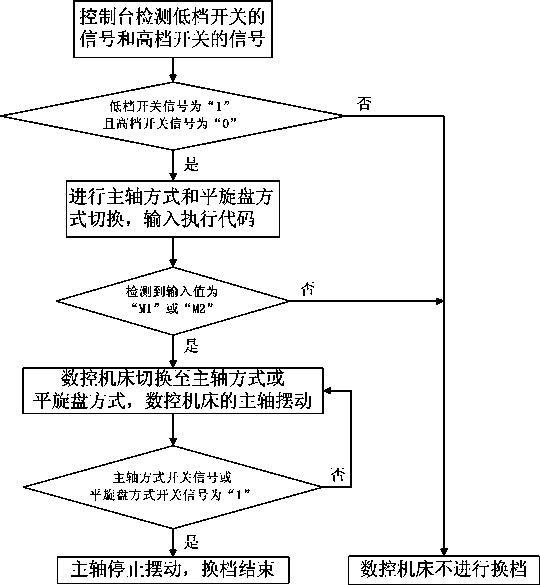

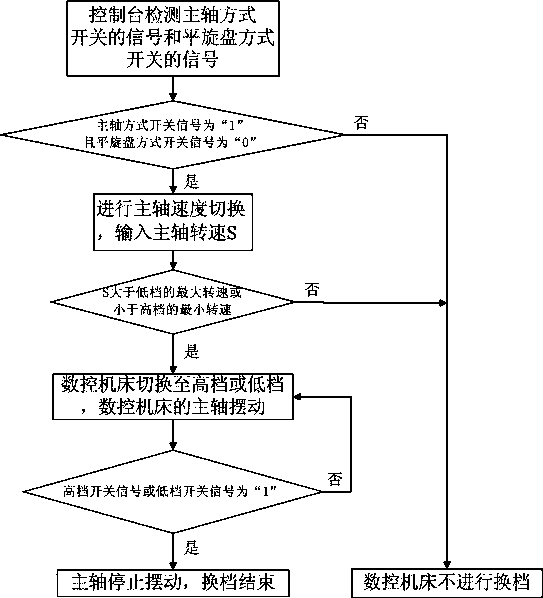

[0023] As shown in the figure, the present invention relates to a control method of a CNC machine tool with a fixed flat-rotating disk, the control method includes a spindle mode and a flat-rotating disk mode switching method and a spindle speed switching method; the console of the CNC machine tool is connected with Spindle mode switch 1, level rotary disc mode switch 2, spindle low gear switch 3 and spindle high gear switch 4;

[0024] Set "M1" on the console as the execution code for shifting gears to the spindle mode, and set "M2" as the execution code for shifting gears to the flat rotary disc mode; The rotating speed is lower than the maximum rotating speed of the high gear, the minimum rotating speed of the horizontal rotating gear is smaller than the maximum rotating speed of the horizontal r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com