A device that outputs printed products fed in a product stream into two mutually independent stacks

A printing product and product flow technology, applied in the direction of conveyors, transportation and packaging, stacking receiving devices, etc., can solve the problems of expensive small batch orders, technical consumption of cross stackers and book block stackers, and easy interference of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

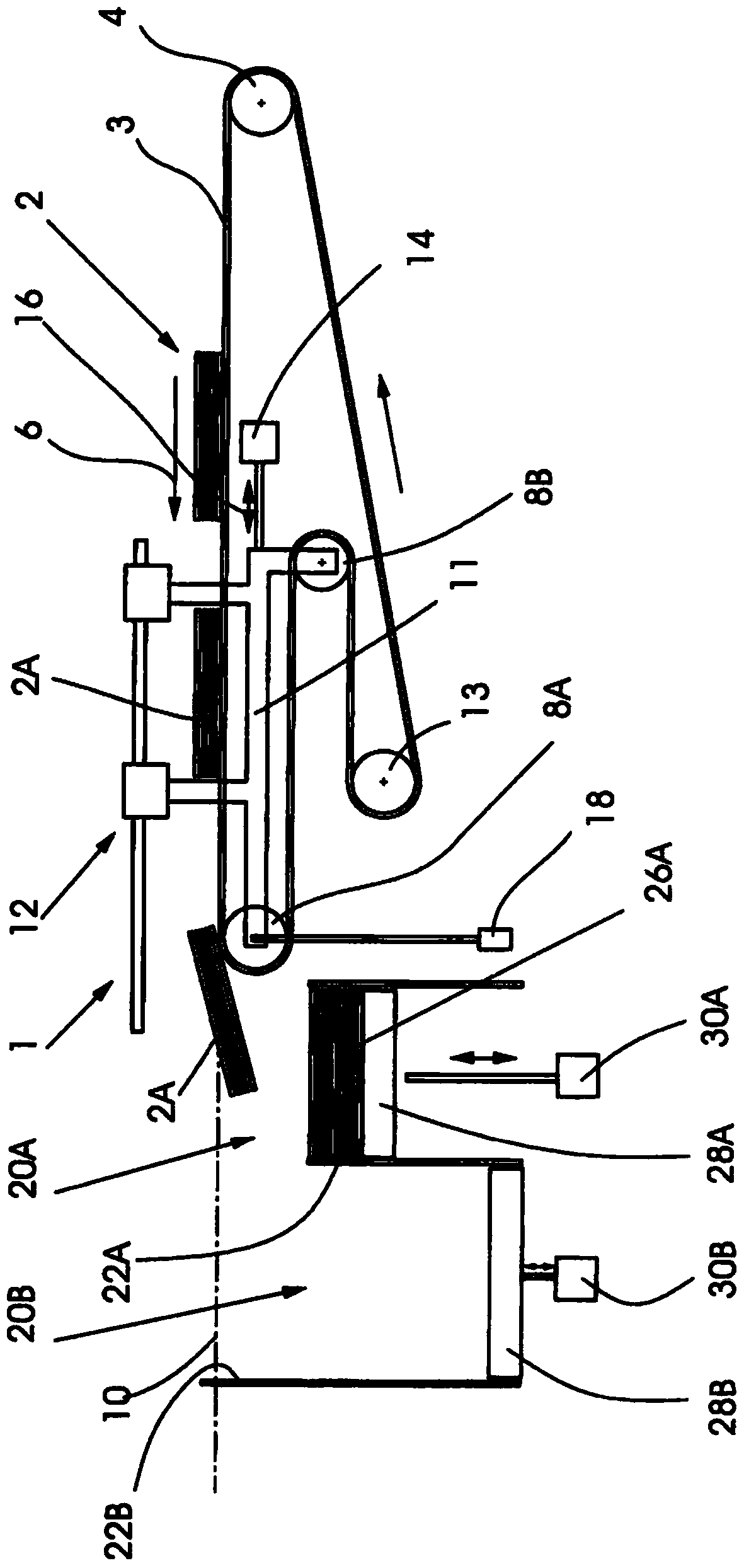

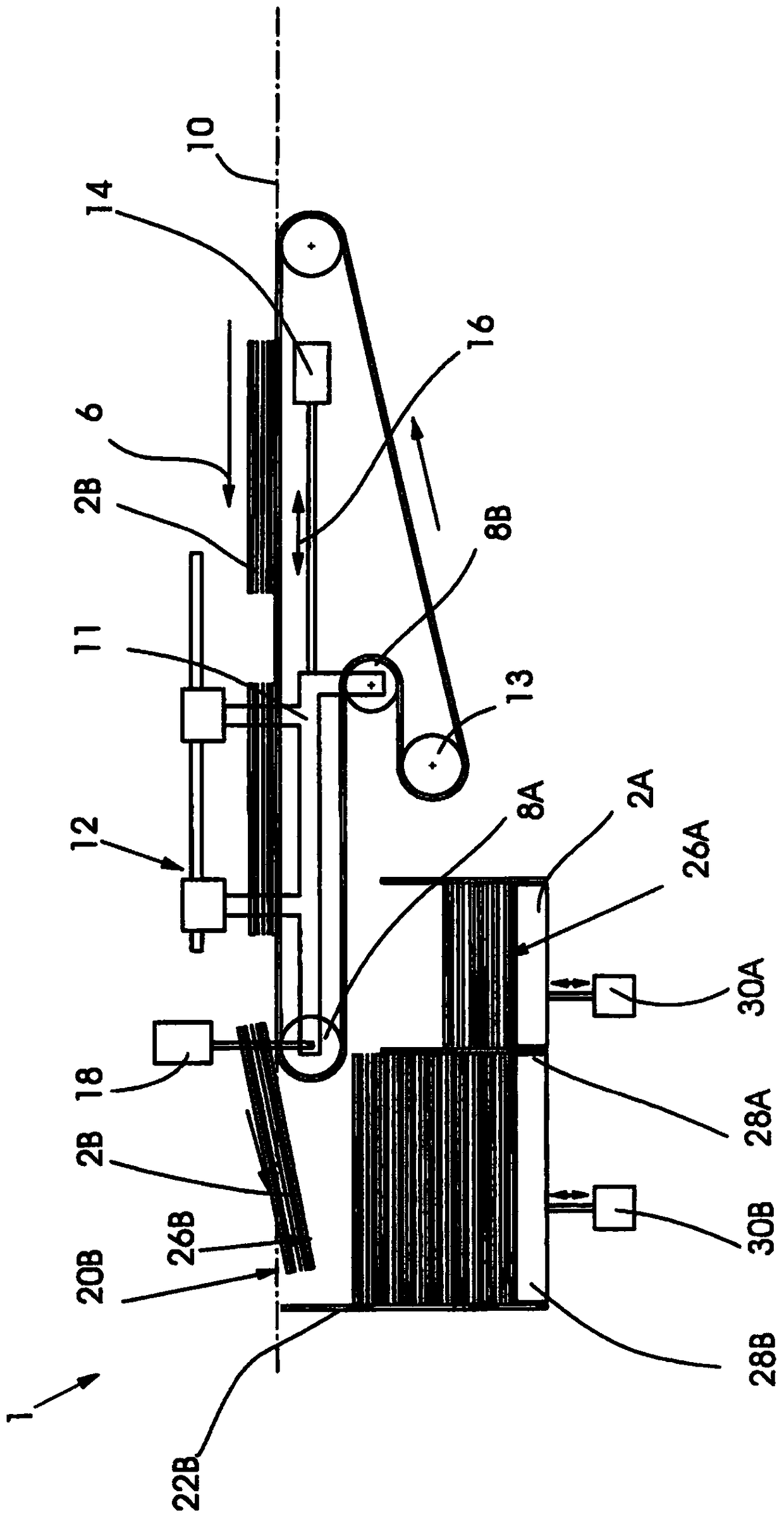

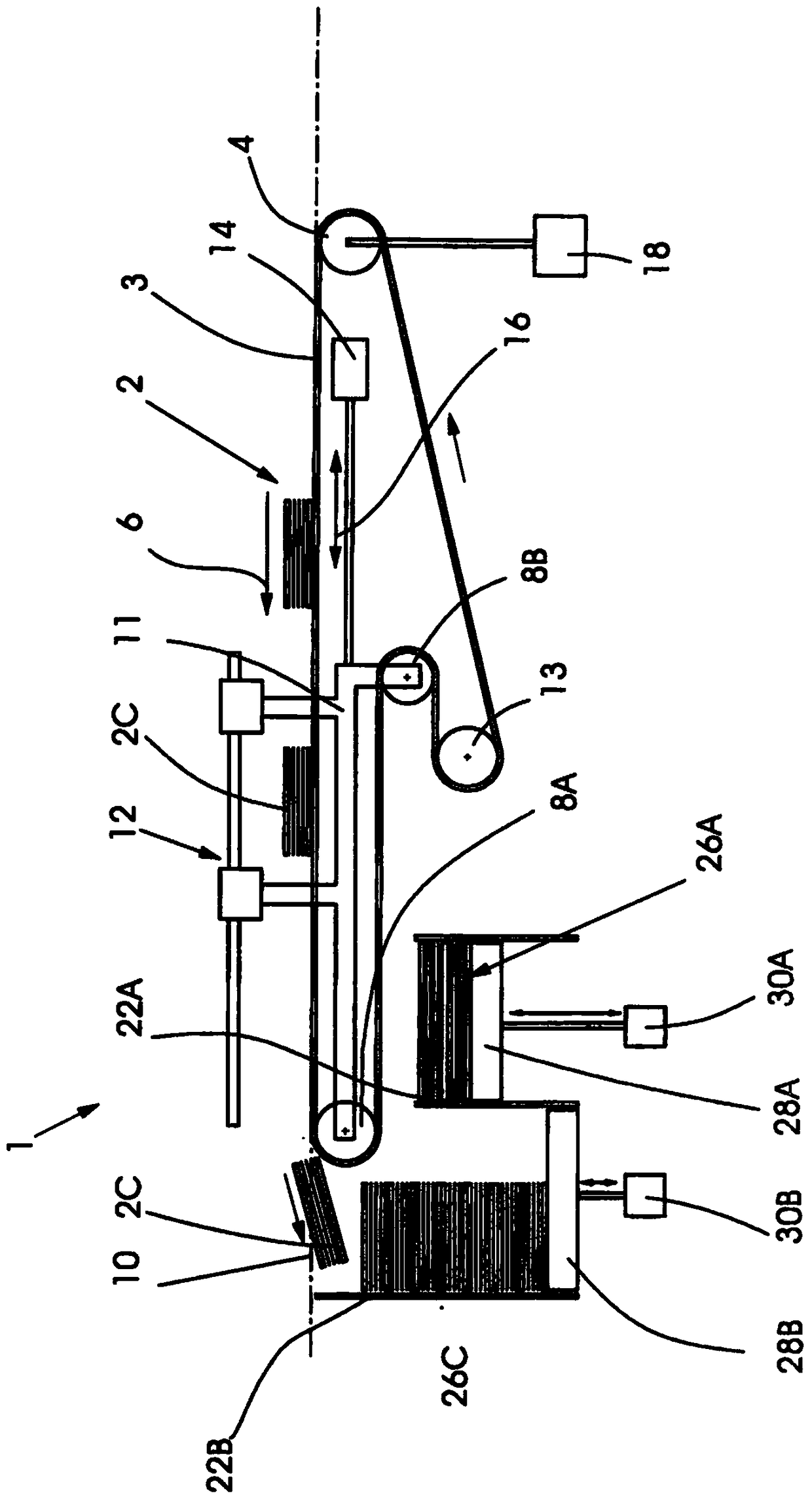

[0030] like Figures 1 to 5 As shown, the device 1 according to the invention for outputting the printed products 2A, 2B, 2C provided in the product stream 2 comprises an endless conveyor belt 3, before the printed products are fed by a pre-printing press (not shown in detail). After production, such as a digital printing press or a perfect binding machine, the printed products 2A, 2B, 2C are placed on the conveyor belt.

[0031] Here, the printed products 2A, 2B, 2C have different specifications, which are figure 1 Reference numerals 2A for smaller sizes in figure 2 Reference numerals 2B and 2B for larger sizes in image 3 Reference numeral 2C for the smaller size in .

[0032] if available from figure 1 , 2 As can be seen in further detail from the figures of and 3, the device 1 according to the invention comprises a first deflection roller 4 fixed to the machine frame, which deflection roller is preferably rotatably mounted in a side wall (not shown in detail). Viewe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com