A method for preparing high-activity aluminum hydroxide suspension and its reaction with pure aluminum powder to produce hydrogen

A technology of aluminum hydroxide and high activity, applied in the field of chemical industry, can solve the problems of corrosiveness, uncontrollable reaction, slow hydrogen production rate, etc., and achieve the effect of cheap price and rich source of aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will now be described below.

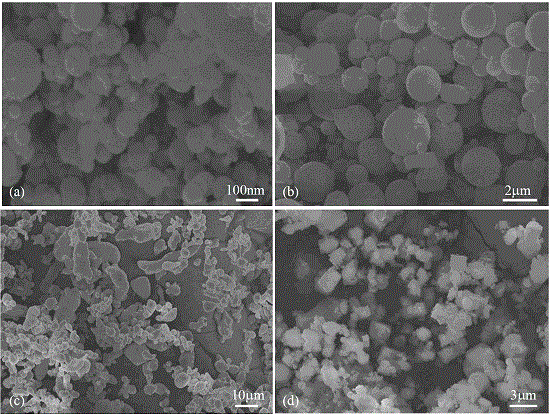

[0027] Such as figure 1 Shown are the micron and nanometer size pure aluminum powder (Al) and commercial aluminum hydroxide (Al(OH) 3 ) Scanning electron microscope (SEM) photo of the powder, the shape of the aluminum particles is irregular, and the size has a certain distribution.

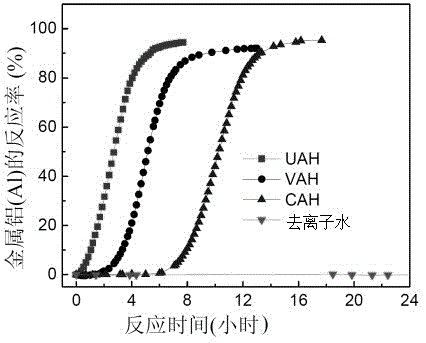

[0028] A method for preparing high-activity aluminum hydroxide suspension and reacting with pure aluminum powder to produce hydrogen has the following process and steps: 3 methods are used to prepare aluminum hydroxide (Al(OH) 3 ) Suspension: (1) Take a certain amount of micron or nano-sized aluminum (Al) powder and add it to a beaker containing a certain amount of water and mix it evenly, then place the beaker into an ultrasonic bath containing a certain amount of 40oC warm water After ultrasonic treatment for 1 hour, the aluminum powder reacts with water under ultrasonic conditions. After the reaction, aluminum hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com