Vertical range-hood active noise reduction device and noise reduction method with application of device

A technology for range hoods and active noise reduction, which is applied in applications, oil fume removal, household stoves, etc. It can solve the problems of not being able to expand the frequency range of noise reduction, achieve the elimination of main noise pollution sources, expand the frequency range of noise reduction, and reduce the middle and low frequencies. noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

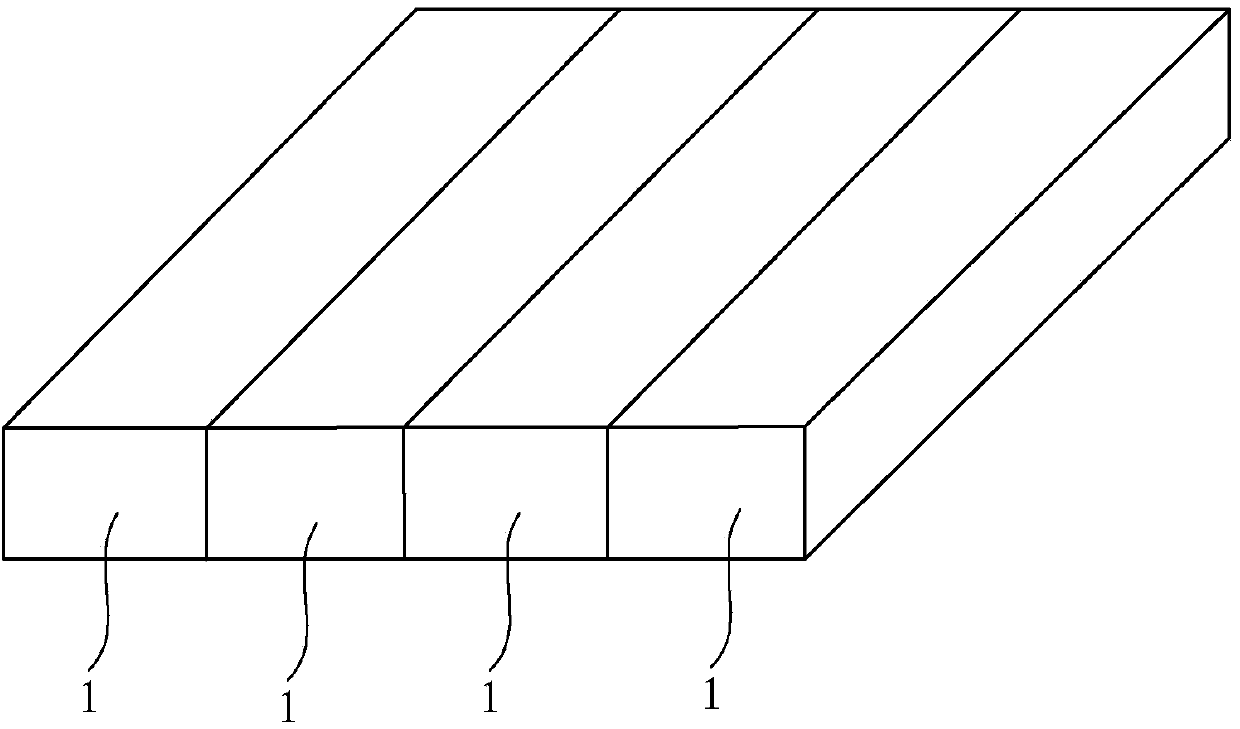

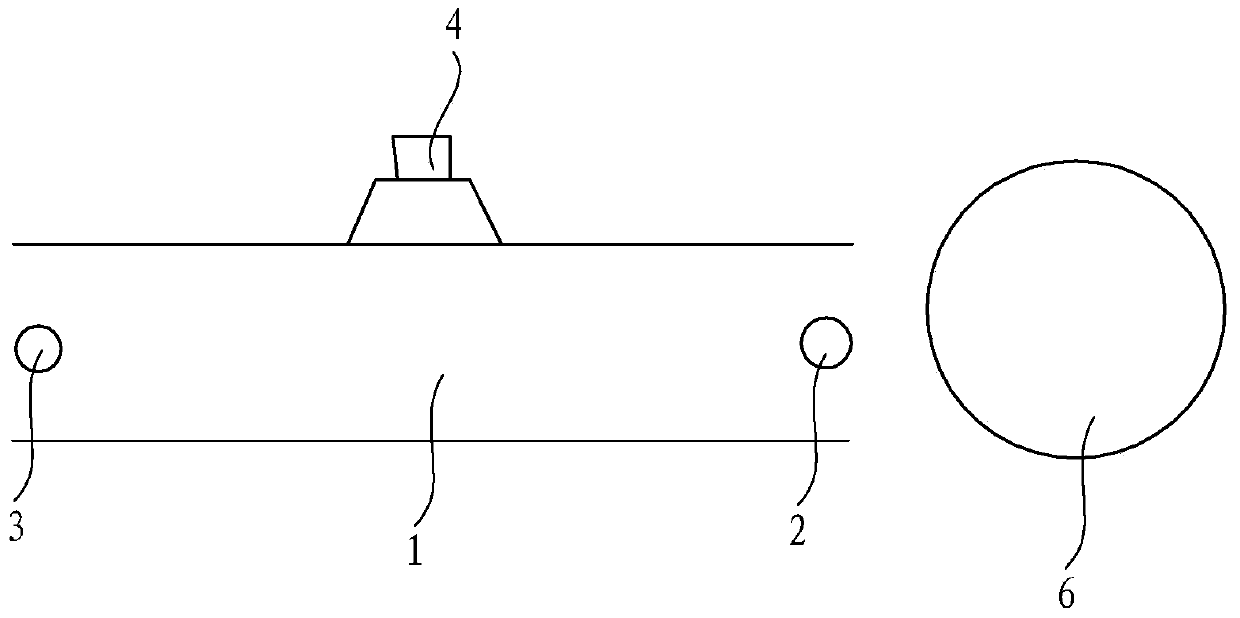

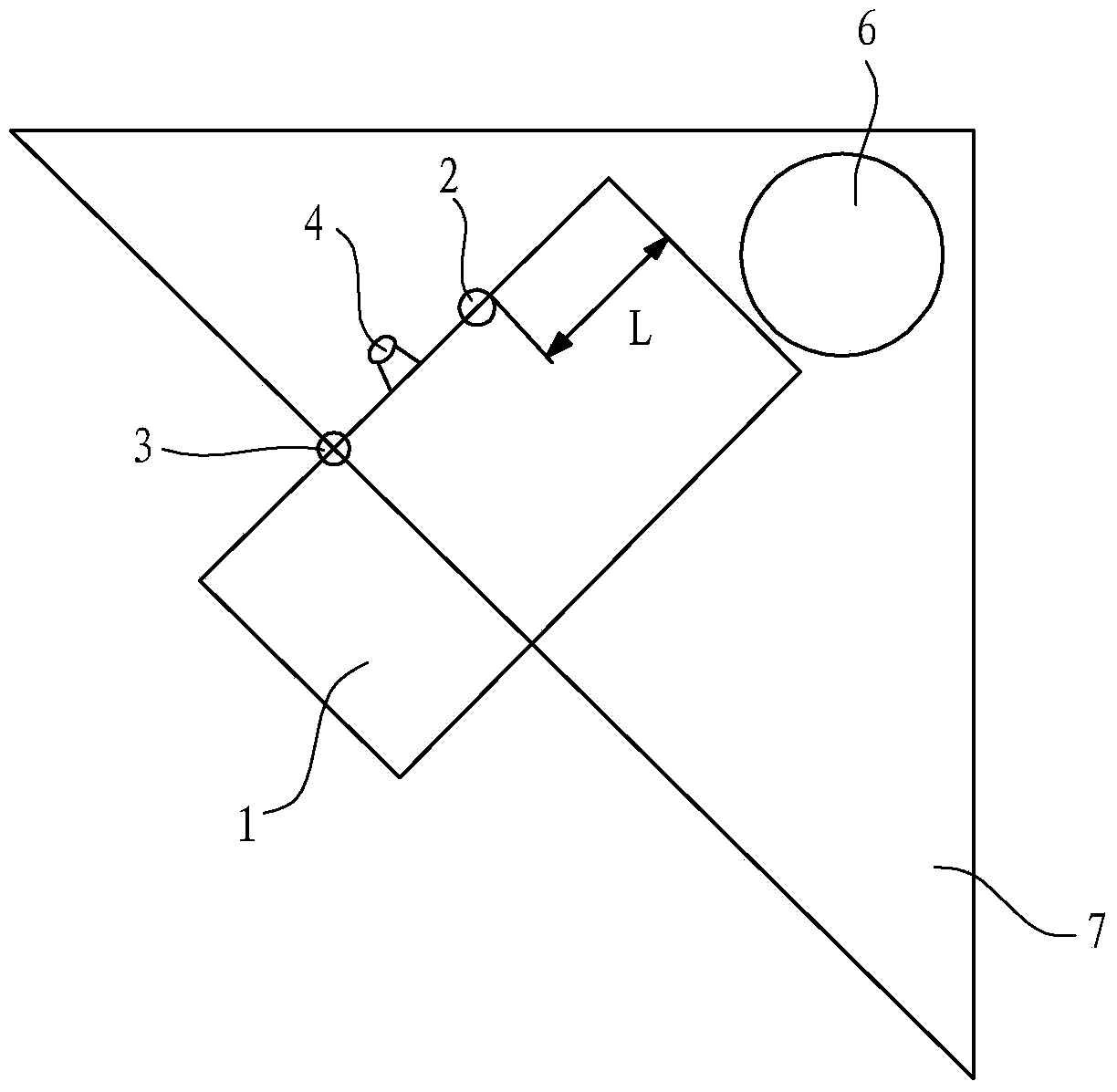

[0031] Such as Figure 1 to Figure 3 As shown, the air inlet of the near-suction range hood in this embodiment is equally divided into four air intake passages 1, and the air intake passages 1 are installed on the smoke collecting hood 7 of the range hood, and each air intake passage 1 A set of independent active control devices is installed inside, each set of active control devices includes a reference microphone 2, an error microphone 3 and a loudspeaker 4, and all active control devices are controlled by an active noise reduction controller 5.

[0032] In this embodiment, the cross section of the air inlet passage 1 is rectangular, and the long side of the rectangular cross section ranges from 0.085m to 0.85m. The length of the air inlet channel 1 is 0.2-0.3m, the reference microphone 2 is installed at the rear end of the air inlet channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com