Method for designing controller of non-minimum-phase constant-temperature continuous stirred tank reactor

A non-minimum phase and design method technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as difficult to ensure zero dynamic stability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

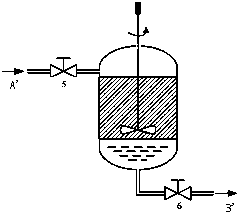

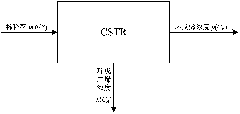

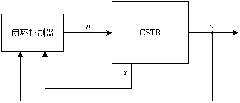

[0064] A nonlinear controller design and construction method of the non-minimum phase isothermal continuous stirred tank reactor of the present invention, its specific implementation scheme is: first, the system to be controlled is accurately feedback linearized according to the feedback linearization theory of nonlinear systems Then, based on the linear quadratic optimal control theory and Lyapunov stability theory, the optimal controller design is carried out for the actual chemical system with nonlinear non-minimum phase characteristics such as cyclopentene produced by CSTR; finally, the DSP controller is used as the control The core is programmed to realize the controller designed by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com