Automatic integrated line clamping and threading device for motor rotor

A technology of threading device and motor rotor, which is applied in electromechanical devices, electric components, manufacturing of motor generators, etc. Product consistency is high, the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

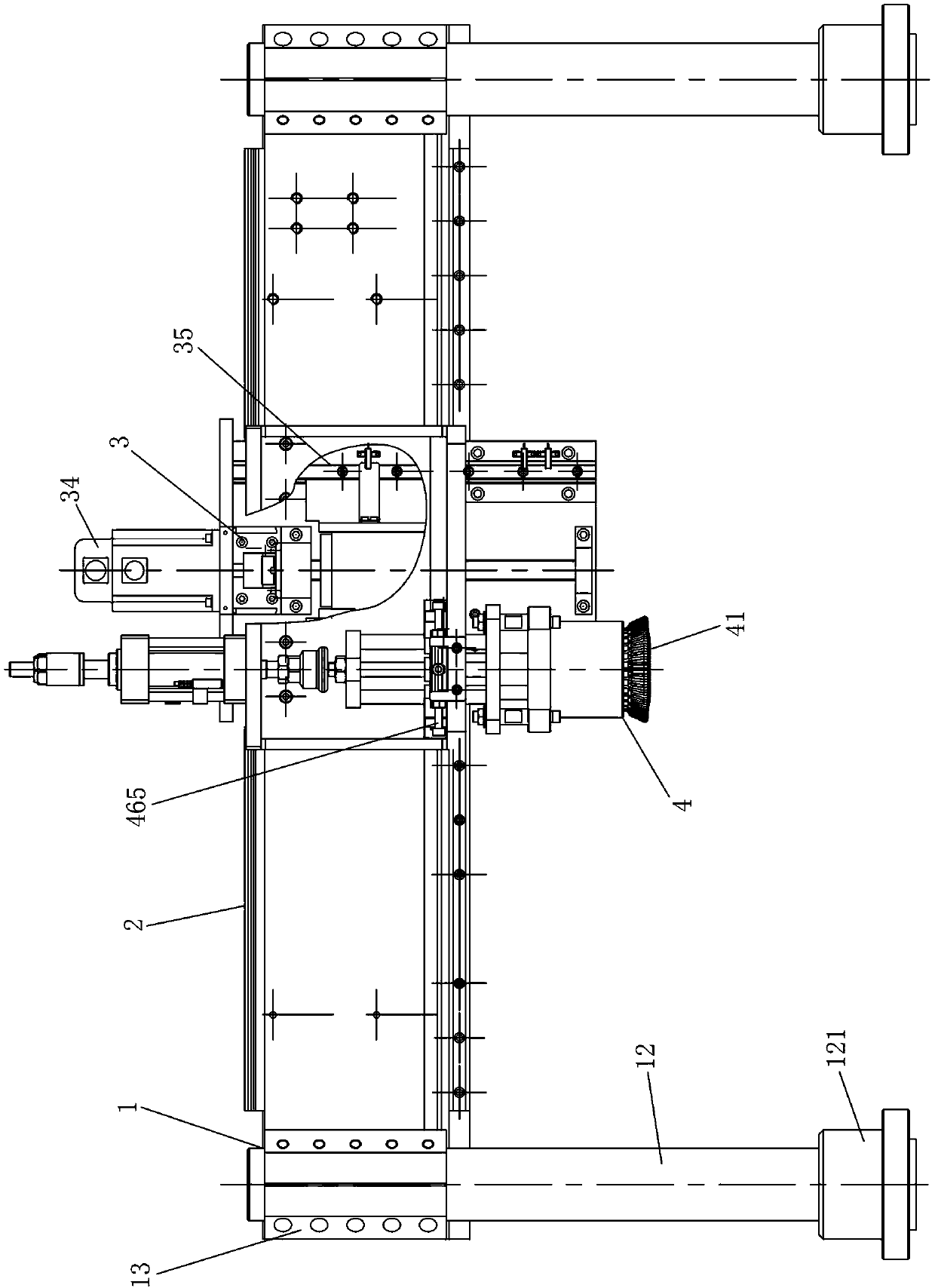

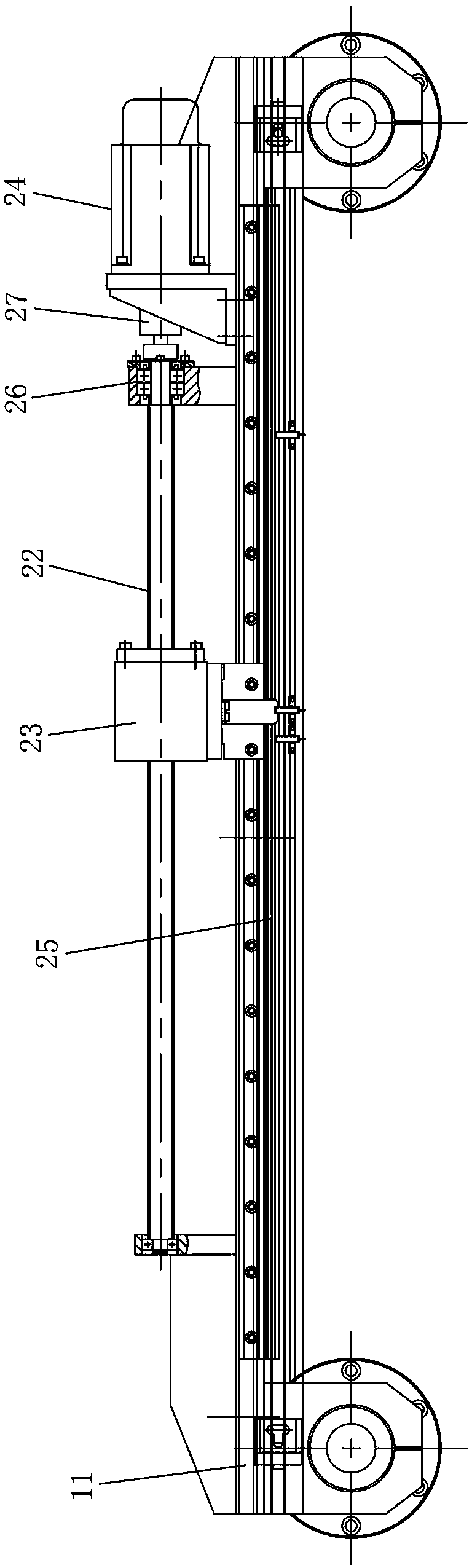

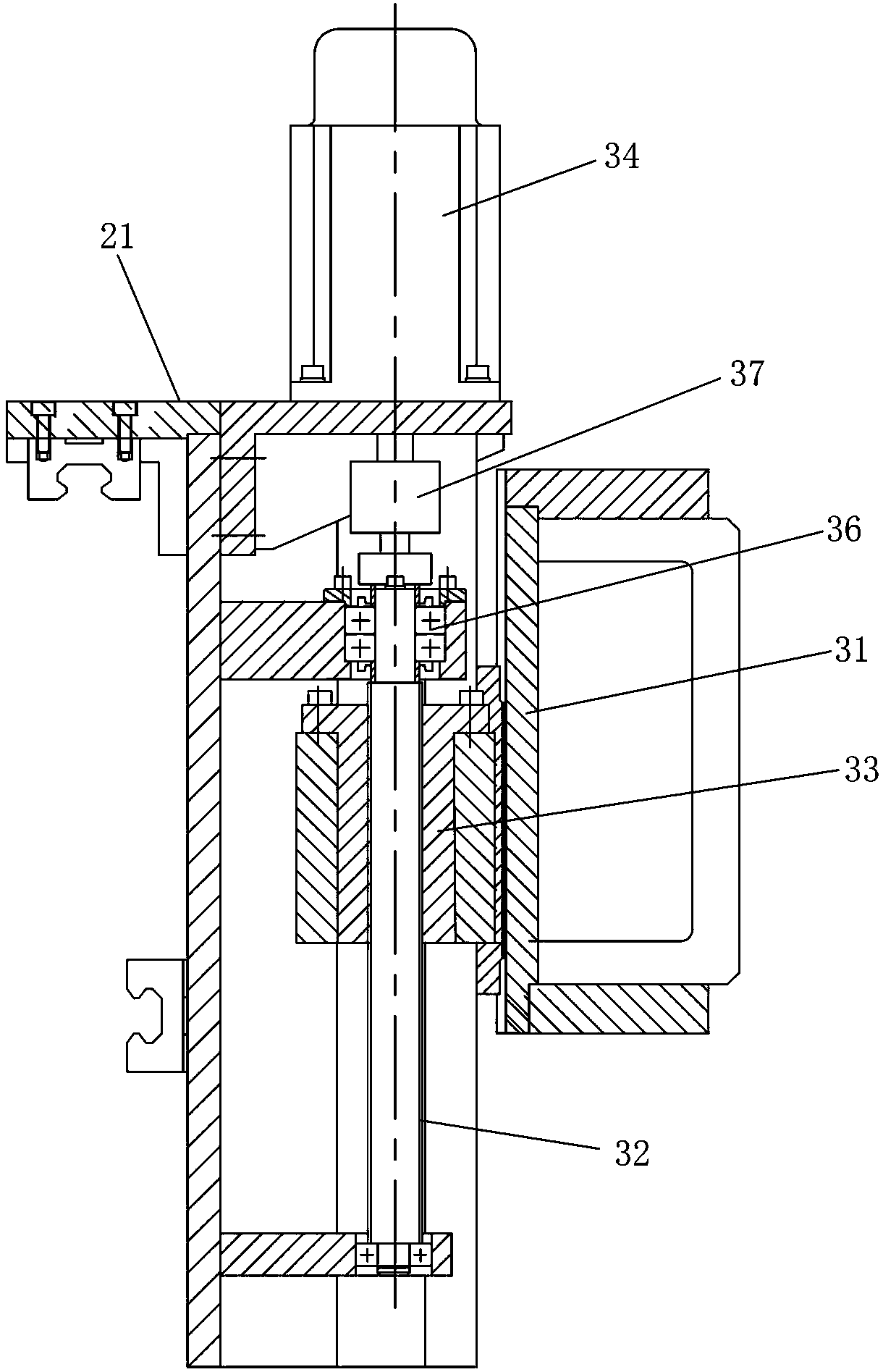

[0028] like figure 1As shown, the automatic overall clamping and threading device for the motor rotor of the present invention includes a bracket assembly 1, a manipulator 4 for integrally clamping and placing the coil group formed by splitting, pulling and twisting, and a manipulator 4 for driving the manipulator 4 in the clamping station (split The drive assembly that moves between the position of the twist head forming device) and the threading station (the position of the motor rotor), the drive assembly includes the translation drive assembly 2 installed on the bracket assembly 1 and the drive assembly installed on the translation drive assembly 2 The lift drive assembly 3 at the end, the manipulator 4 is installed on the drive end of the lift drive assembly 3, the lift drive assembly 3 can be driven by the translation drive asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com