a tobacco planter

A technology of a seeder and a seeding mechanism, which is applied to the parts of the seeder, the machinery of interval-type quantitative seeding, etc., can solve the problems of low seeding efficiency, complex structure, low degree of mechanization, etc., and achieves high seeding efficiency, fast seeding speed and precision high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

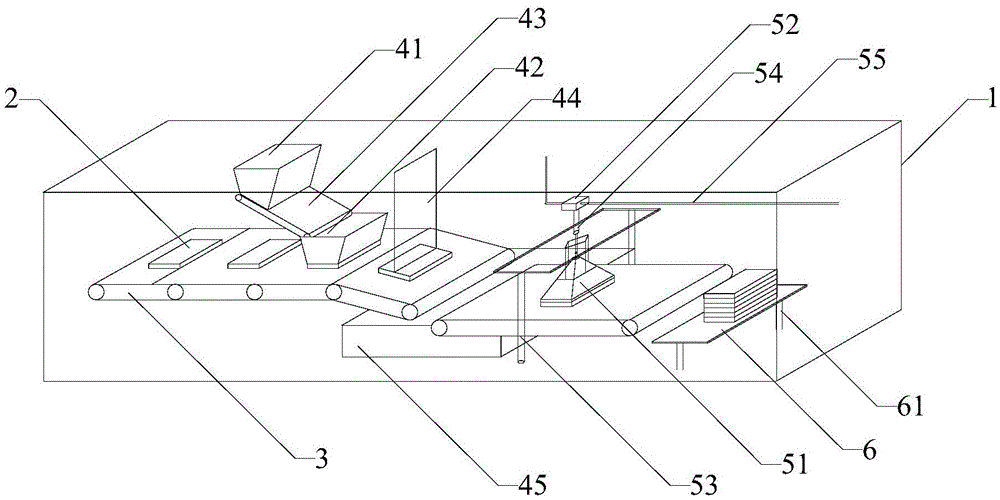

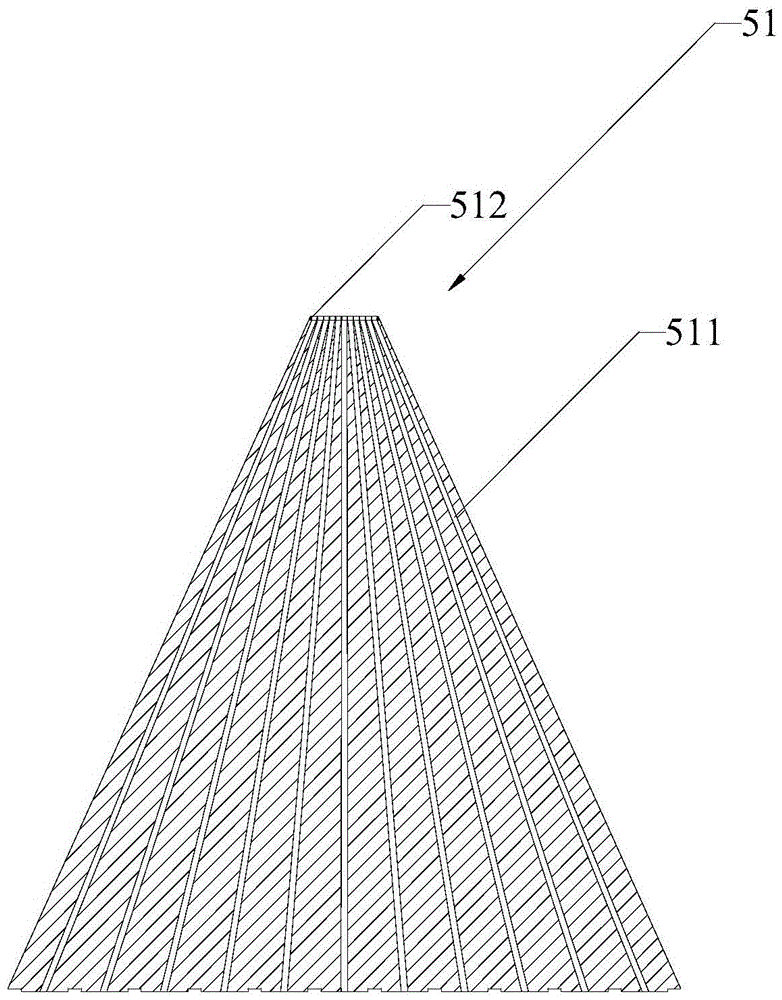

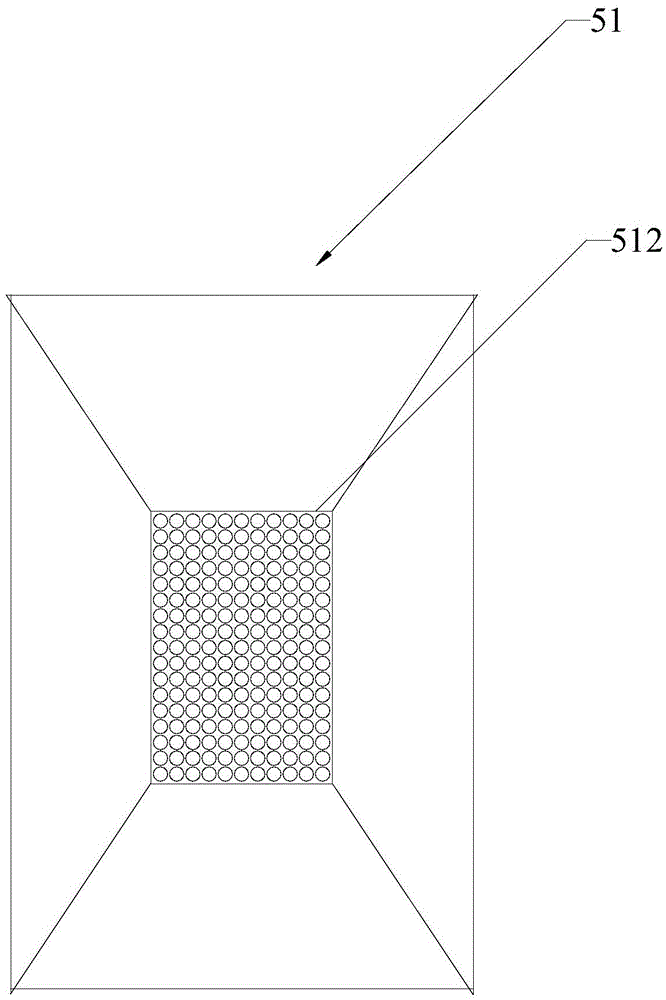

[0026] read on figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 , this embodiment provides a specific implementation of the tobacco seeder, the sowing device of the tobacco seeder of the present embodiment also includes a guide rail 55, the guide rail 55 is fixed on the frame 1 and is located above the lifting mechanism, the seed container The setter is fixed on the guide rail 55, and the seed adsorber 52 is slidably arranged on the guide rail 55. The lifting mechanism includes a first hydraulic cylinder 53 and a second hydraulic cylinder 54, and the first hydraulic cylinder 53 and the substrate are compacted and sowed Mechanism 51 is connected, and described second hydraulic cylinder 54 is connected with seed absorber 52; Described substrate compaction sowing mechanism 51 is cone shape, and the cone top of described substrate compaction sowing mechanism 51 has opening, and described substrate compaction sowing mechanism 51 has opening, and described matrix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com