A stone mill flour machine

A flour mill and stone grinding technology, applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of low degree of automation, dust splashing, harsh production and processing environment, etc., achieving less dust, high degree of automation, guaranteed taste and scent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

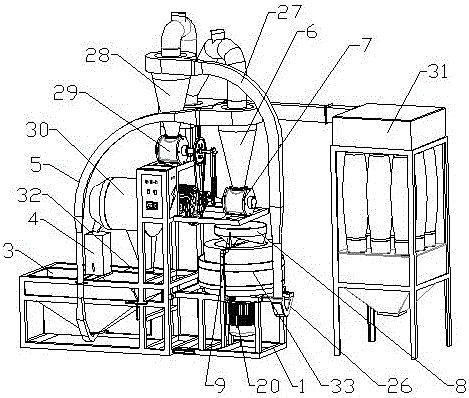

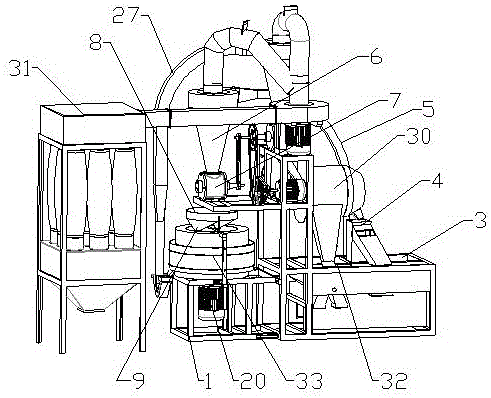

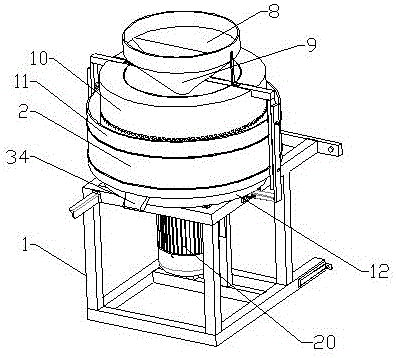

[0025] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 8 As shown, this kind of stone mill flour machine includes a body frame 1, and also includes a stone mill 33 on the body frame 1 and two feeding bins 3 arranged side by side. The feeding bin 3 is provided with a bin change switch. It is connected with the bran changing device 4 above the feeding bin 3, and the two feeding bins 3 have a common discharge pipe 5 (the structure of the bran changing device and the two discharging bins and the use of this part are described in the patent No. CN101879473 B, a new type of grain flour milling single machine is described in detail, and will not be repeated here), the outlet end of the discharge pipe 5 is connected to the first Shakron 6 and the first air locker 7 in sequence, and the first air locker 7 The air device 7 is located above the double-mouth feed hopper 8 of the stone mill. The double-mouth feed hopper 8 is divided in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com