Aggregation device of horizontal planetary ball mill

A planetary ball mill and aggregate device technology, applied in the field of powder grinding, can solve the problems of difficult sealing, large dust, and impossibility of realization, so as to ensure stability and continuity, reduce production and operation costs, and facilitate installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

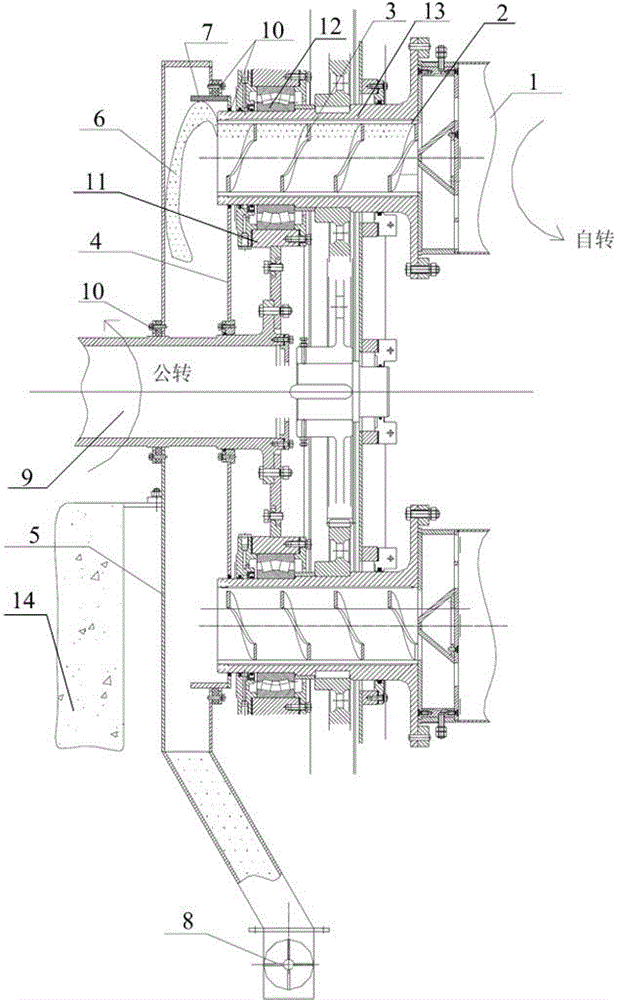

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

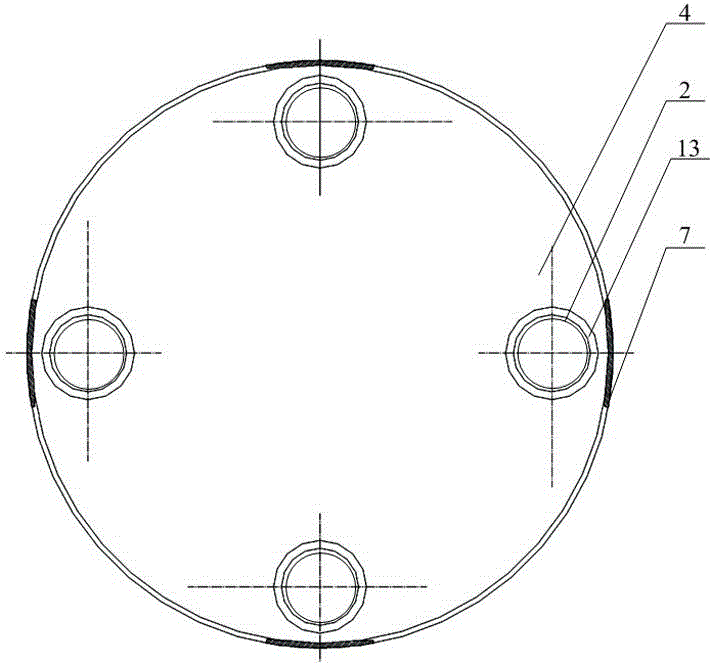

[0019] Such as figure 1 , 2 As shown, the collecting device of the horizontal planetary ball mill of the present invention is used for collecting the forming powder of the existing horizontal planetary ball mill, and includes a hollow shaft 2, an inner spiral blade 3, a revolving disk 4 of the collecting cover, and a fixed shell of the collecting cover 5. There are 4 retaining arcs 7 and air lock valves 8, including 4 hollow shafts 2 and 3 inner spiral blades.

[0020] The horizontal planetary ball mill is equipped with four grinding cylinders 1, the rear end of each grinding cylinder 1 is fixedly connected to one end of the hollow shaft 2, and each hollow shaft 2 is supported on the planetary mill revolution plate 11 through a bearing 12, each The two hollow shafts are correspondingly set in the shaft sleeve 13 and follow the respective connected grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com