Non-contact automatic roller diameter sorting machine

An automatic sorting and non-contact technology, applied in sorting and other directions, can solve problems such as inappropriate detection of roller diameter measurement, complex mechanical structure of automatic sorting machine, wear and tear of sensor probe, etc., to achieve simple structure and easy control , Ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

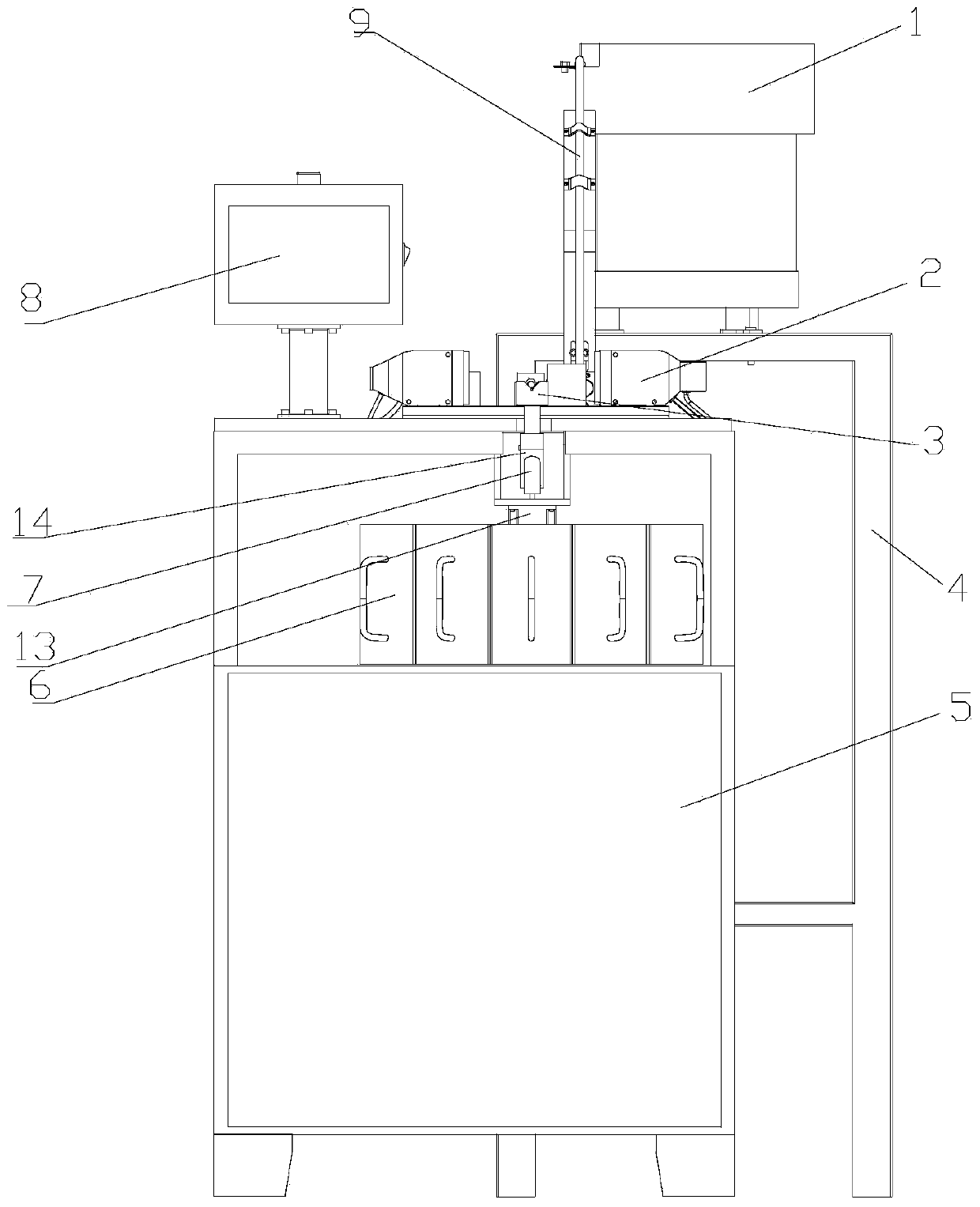

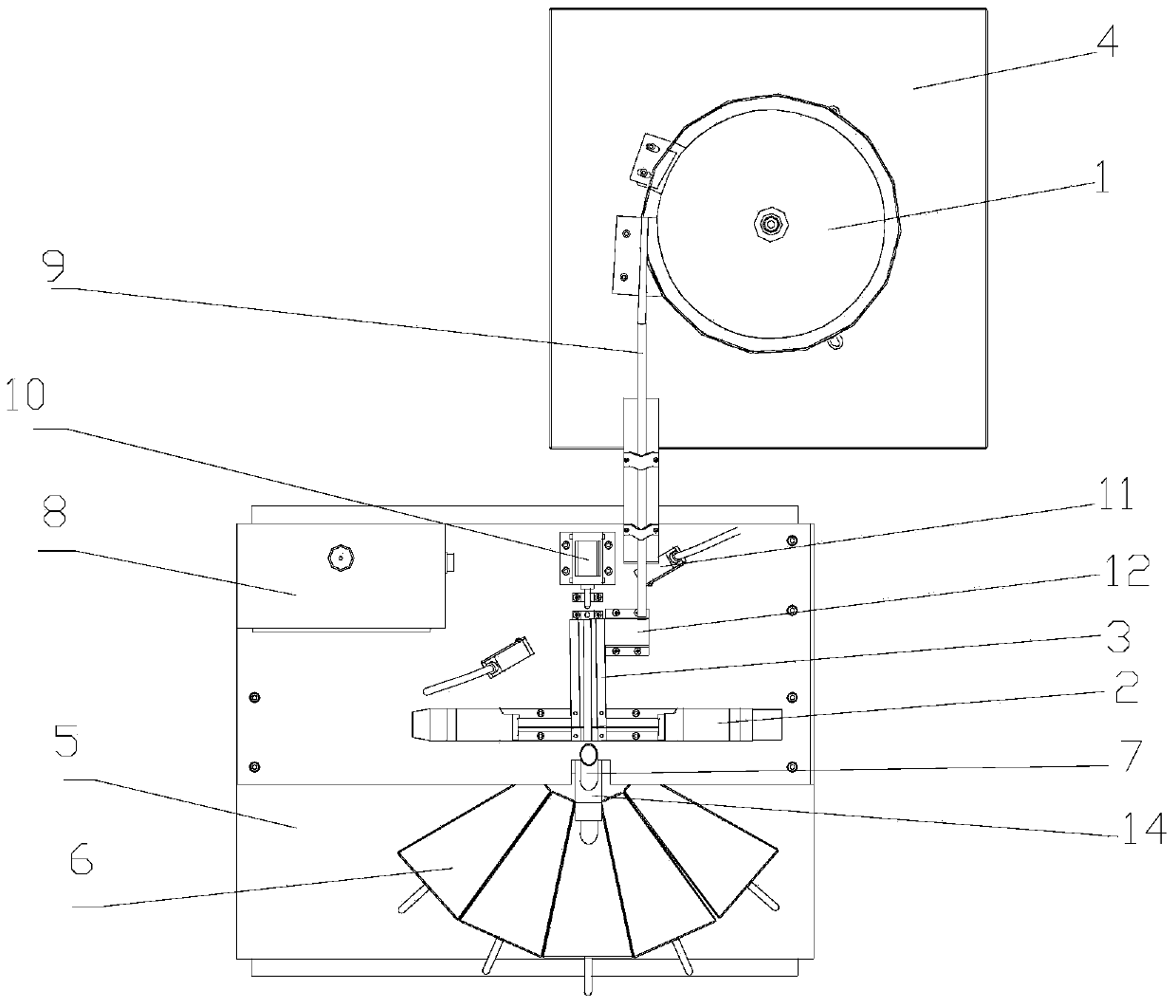

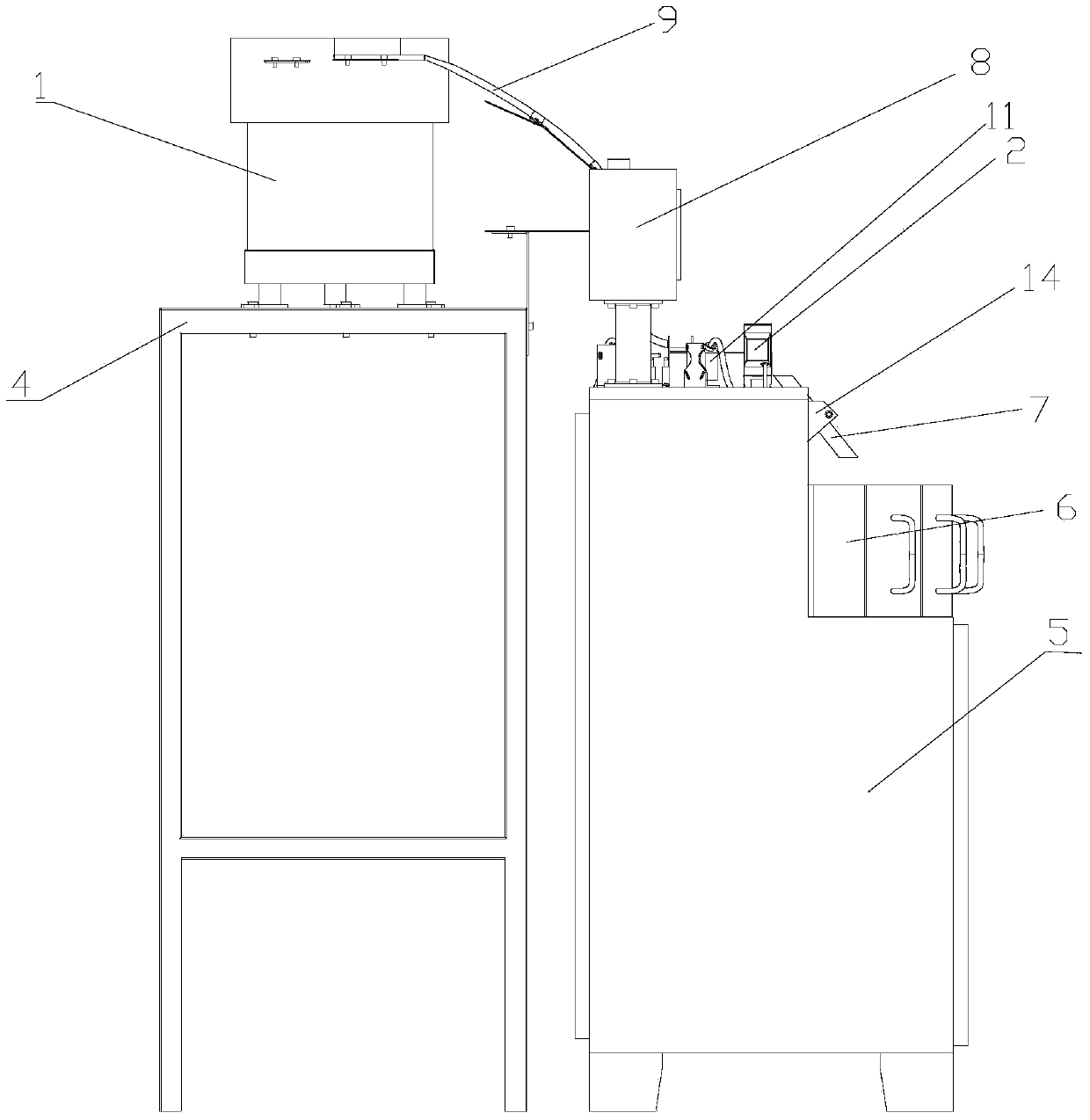

[0010] attached figure 1 A schematic diagram of the structure of the present invention is shown, and a laser sensor 2 is used as a detection device to realize non-contact measurement.

[0011] A non-contact cylindrical roller diameter automatic sorting machine uses a laser sensor as a detection device to realize non-contact measurement. The sorting machine is mainly composed of a feeding module, a feeding module, a detection module and a sorting module. The rollers to be tested fall into the feeding module neatly and orderly after passing through the orientation alignment of the feeding device. Send to the detection position, the detection module detects the roller diameter value, and finally sorts according to different measurement results through the sorting module to complete the entire automatic measurement and sorting process.

[0012] The non-contact cylindrical roller diameter automatic sorting machine is composed of a feeding device, a feeding device, a detecting devi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap