Multi-station rotary support special for rotary washing device

A multi-station and equipment technology, applied in cleaning methods and tools, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems affecting wafer cleaning effects, high dynamic balance value, and decreased wafer cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

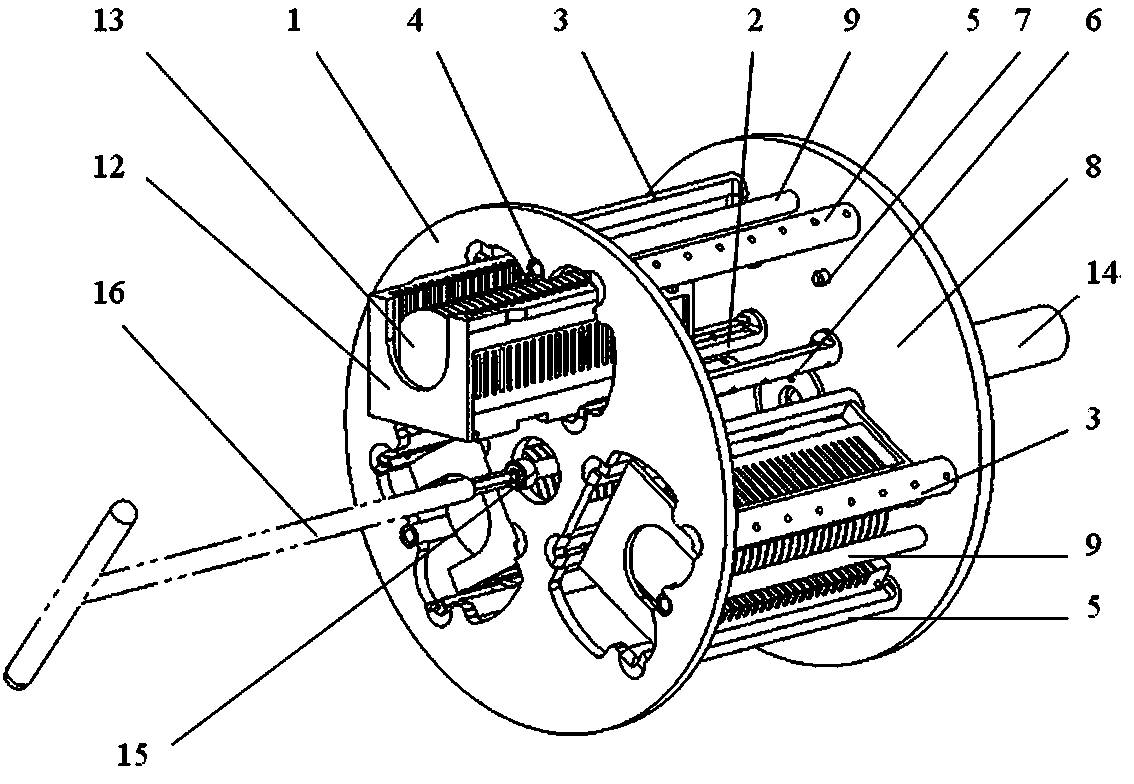

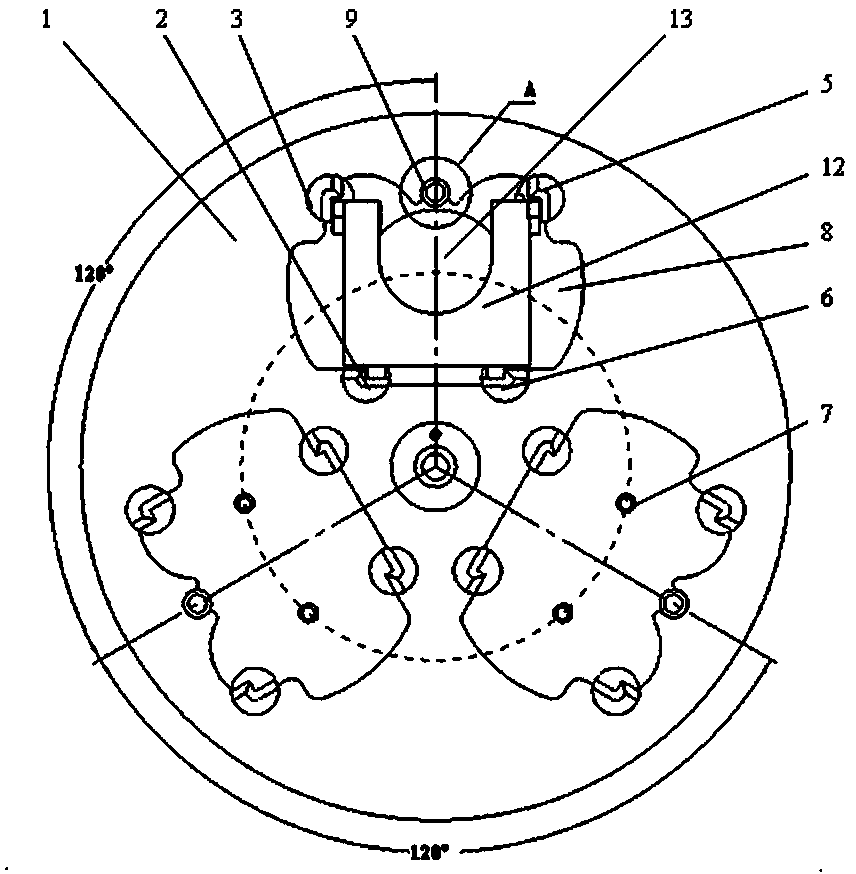

[0020] like figure 1 , figure 2 As shown, the multi-station turntable dedicated to the rotary washing equipment of the present invention includes a front tray 1 and a rear tray 8, and three stations for placing wafer cassettes 12 are arranged between the front tray 1 and the rear tray 8. The outer surface of the front plate 1 is provided with three wafer box inlets and outlets. A wafer box inlet and outlet and a station form a group of station structures. The axis lines of the three groups of station structures are all parallel to and at equal distances from the rotation axis lines of the special multi-station turntable for rotary washing equipment. The three sets of station structures are evenly distributed at 120° in the special multi-station turntable for rotary washing equipment.

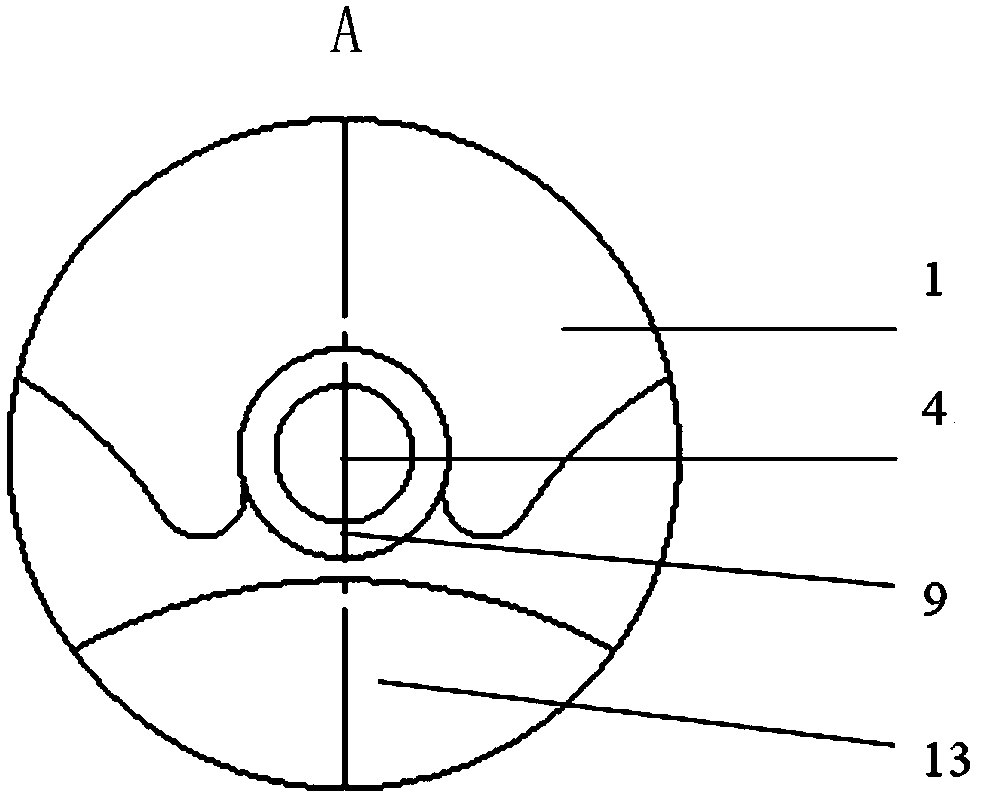

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 7 As shown, each group of station structures includes an outer left strut 3, an outer right strut 5, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com