Surface pretreatment method of annular bonded NdFeB magnet

A surface pretreatment, NdFeB technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, circuits, etc., to prevent corrosion, avoid damage to the adhesive, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

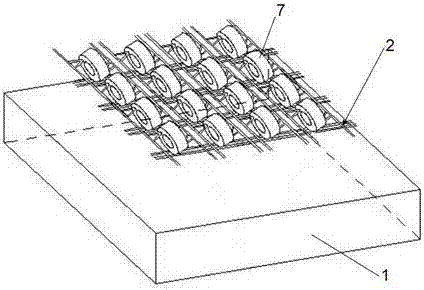

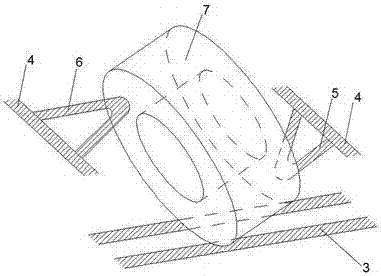

[0025] like figure 1 , 2 As shown, the ring-shaped bonded NdFeB magnet surface pretreatment method is characterized in that: comprising the following steps:

[0026] A ring-shaped bonded NdFeB magnet surface pretreatment method, characterized in that: comprising the following steps:

[0027] (i) Place the bonded NdFeB magnet 7 obliquely in the cleaning hanger 2, the hanger 2 includes parallel transverse struts 3 supporting the side of the bonded NdFeB magnet 7 and the two sides of the bonded NdFeB magnet 7 The longitudinal struts 4, the longitudinal struts 4 on both sides are respectively provided with an upwardly inclined upper limit protrusion 5 and a downwardly inclined lower limit protrusion 6 supporting the upper and lower end surfaces of the bonded NdFeB magnets 7, and the bonded NdFeB magnets 7. Form four-point oblique positioning in the hanger 2;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com