Continuous extrusion mold for C-shaped slot row

An extrusion die and C-groove technology, applied in the direction of metal extrusion dies, etc., can solve problems such as easy breakage, inability to continuously extrude, product dimensional accuracy, and surface quality cannot be effectively controlled, so as to reduce load and product The effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

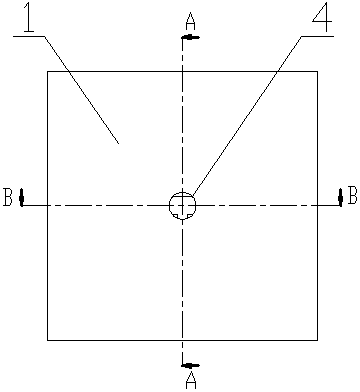

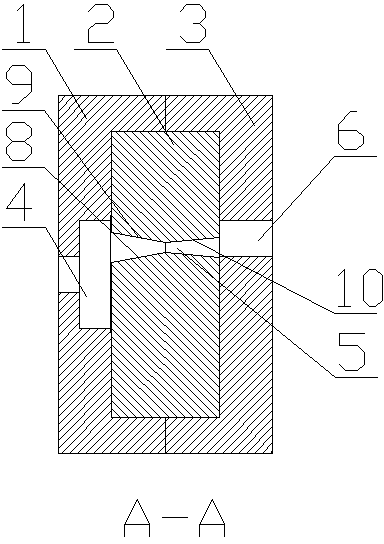

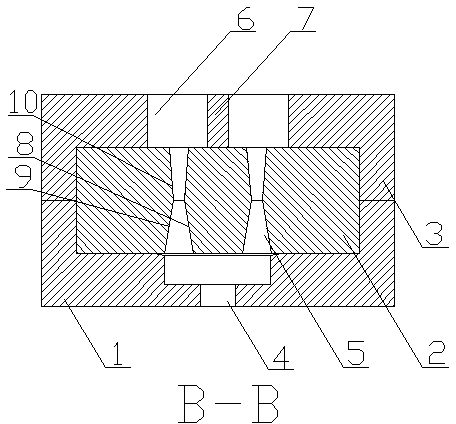

[0017] Such as figure 1 , 4 As shown, a C-shaped groove row continuous extrusion die includes a front cover 1, a mold core 2 and a rear cover 3. After the front cover 1 and the rear cover 3 are molded together, a columnar cavity is formed, and the mold core 2 is fixedly installed on the In the mold cavity, the center of the front cover 1 is provided with a circular channel 3, the center of the mold core 2 is provided with a C-shaped cavity 5, the center of the back cover 3 is provided with a rectangular channel 6, and the center line of the rectangular channel 6 is provided with a convex The platform 7, the circular channel 4, the C-shaped cavity 5, and the rectangular channel 6 are sequentially connected to form a C-shaped groove row extrusion channel.

[0018] Such as figure 2 , 3 As shown, the circular channel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com