Special-shaped special steel wire and strip production line

A technology of special steel and steel wire steel, which is applied in the field of special-shaped special steel wire and strip production line, can solve the problems of high price, surprise and high price, and achieve the effects of good product quality, high automation level and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

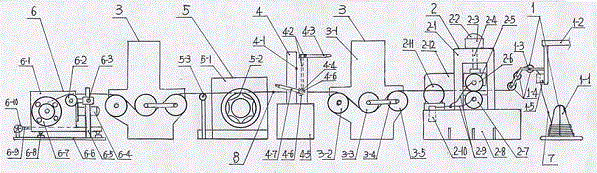

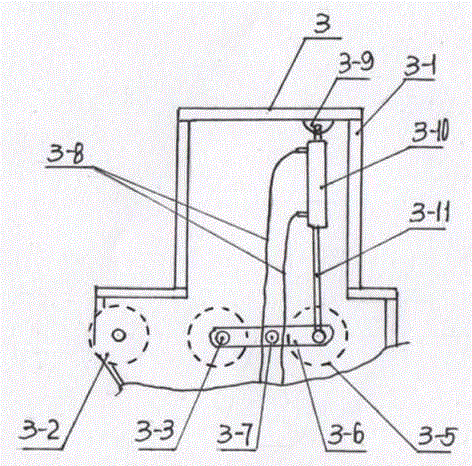

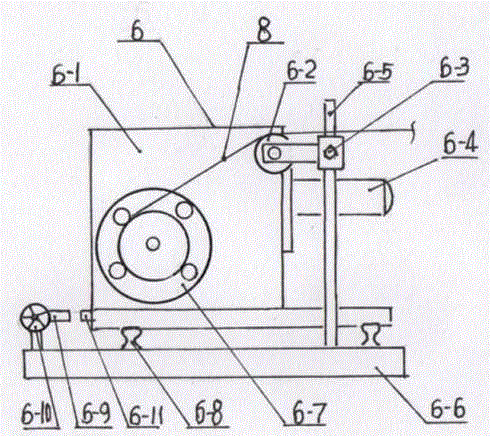

[0012] Embodiments, with reference to the accompanying drawings, a special-shaped steel wire strip production line, including a lead mechanism 1, a double rolling mill 2, a four-roll forming machine 4 and a tractor 5; between the double rolling mill 2 and the four-roll forming machine 4 The first tensioner 3 is installed; the second tensioner 3 is installed between the traction machine 5 and the coiling steel belt machine 6; the wire mechanism 1, the double rolling machine 2 and the first tensioner 3 All are connected by steel wire 7; the four-roll forming machine 4, traction machine 5, the second tension machine 3 and the coiling steel strip machine 6 are all connected by steel strip 8; two tension machines 3 (see attached figure 1 , 2 ) are identical in structure, and the front of the machine housing 3-1 is movably equipped with an incoming steel wire guide wheel 3-5, an adjustment steel wire pressure wheel 3-3 and an outlet steel wire guide wheel 3-2; the adjustment steel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com