Forming die for tooth disc forging

A technology for forming molds and forgings, which is applied in the field of forming molds for tooth disc forgings, can solve problems such as easy collapse angles, and achieve the effects of reducing processing difficulty, benefiting processing, and solving collapse angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0027] The "one embodiment" or "embodiment" referred to herein refers to a specific feature, structure, or characteristic that can be included in at least one implementation of the present invention. The appearances of "in one embodiment" in different places in this specification do not all refer to the same embodiment, nor are they separate or selectively mutually exclusive embodiments with other embodiments.

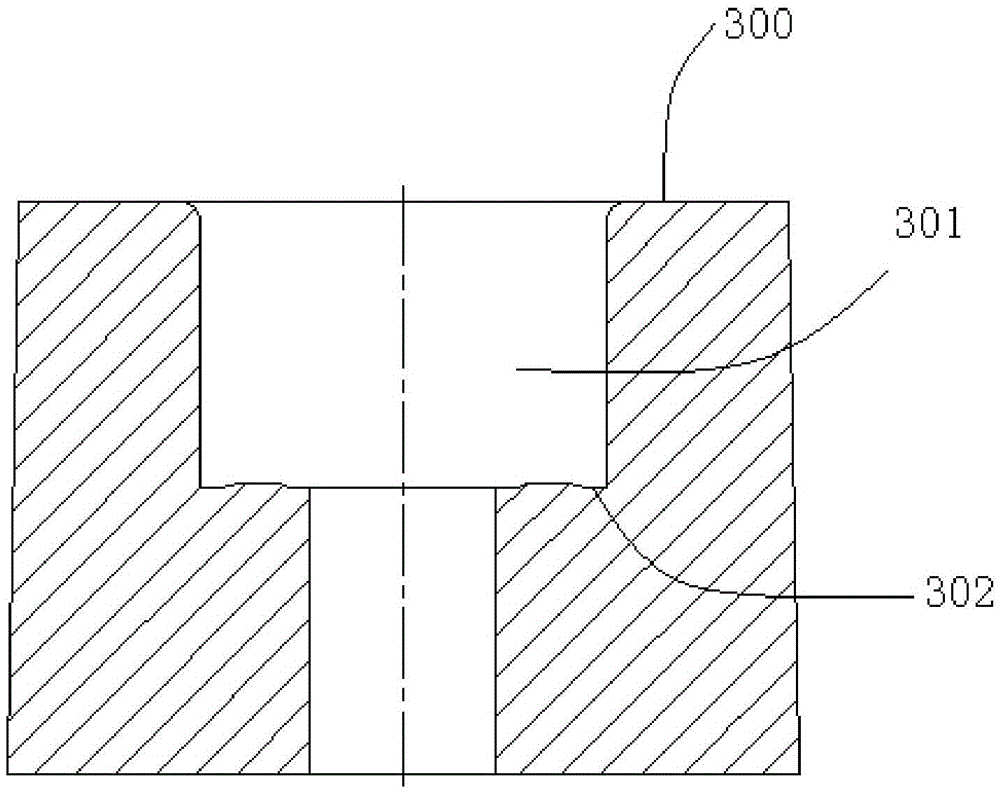

[0028] See Figure 4 with Figure 5 , Figure 4 It is a schematic diagram of the structure of the upper mold of the present invention; Figure 5 It is a schematic diagram of the structure of the concave mold of the present invention. Such as Figure 4 to 5 As shown, the mold includes an upper mold 400 and a female...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com