A feeding mechanism of a button battery packaging machine

A feeding mechanism and button battery technology, which is applied in packaging and other directions, can solve the problems of increasing production costs, low production efficiency, and slow processing speed of manufacturers, and achieve the effects of improving work efficiency, saving manual operations, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

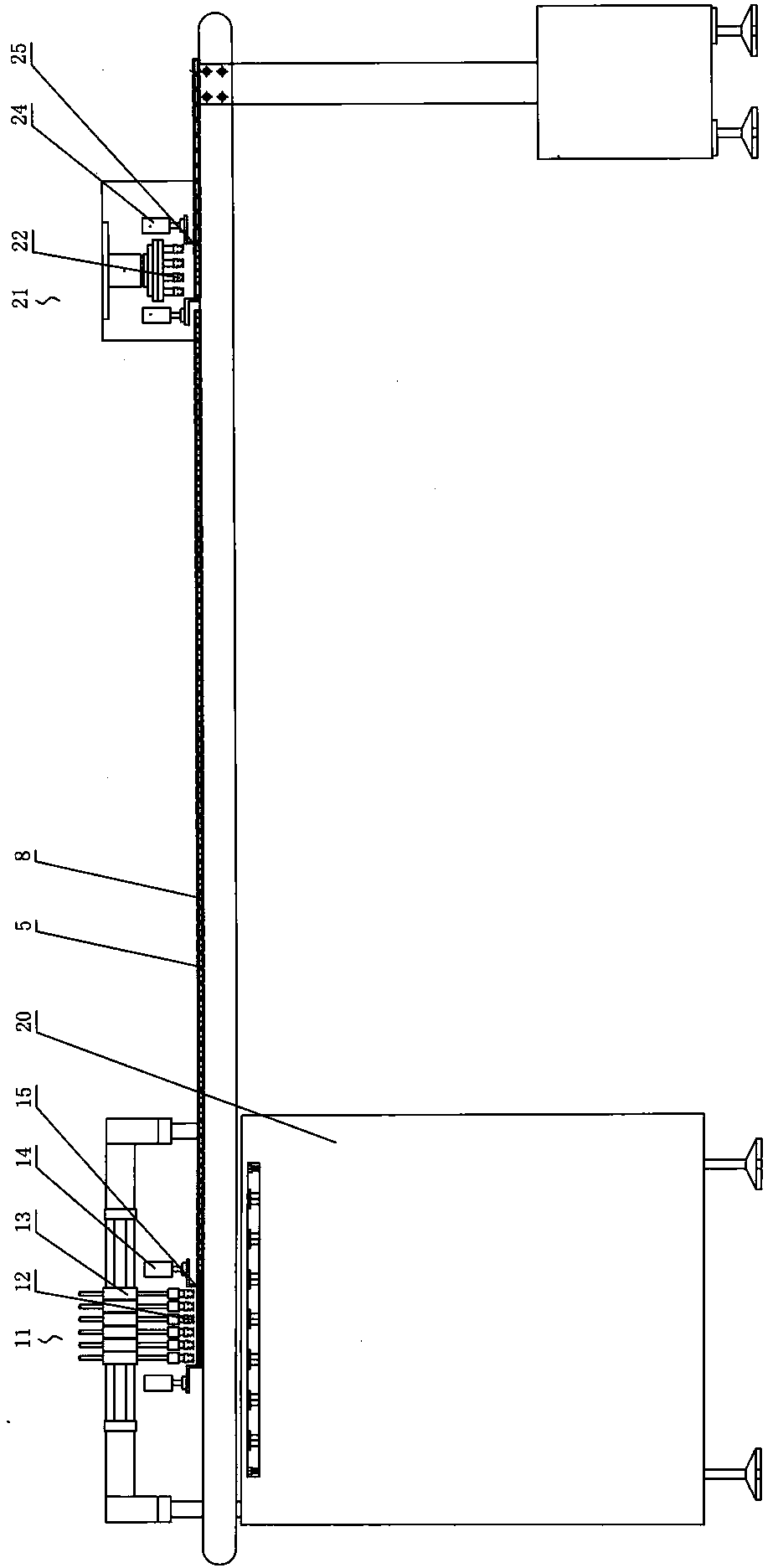

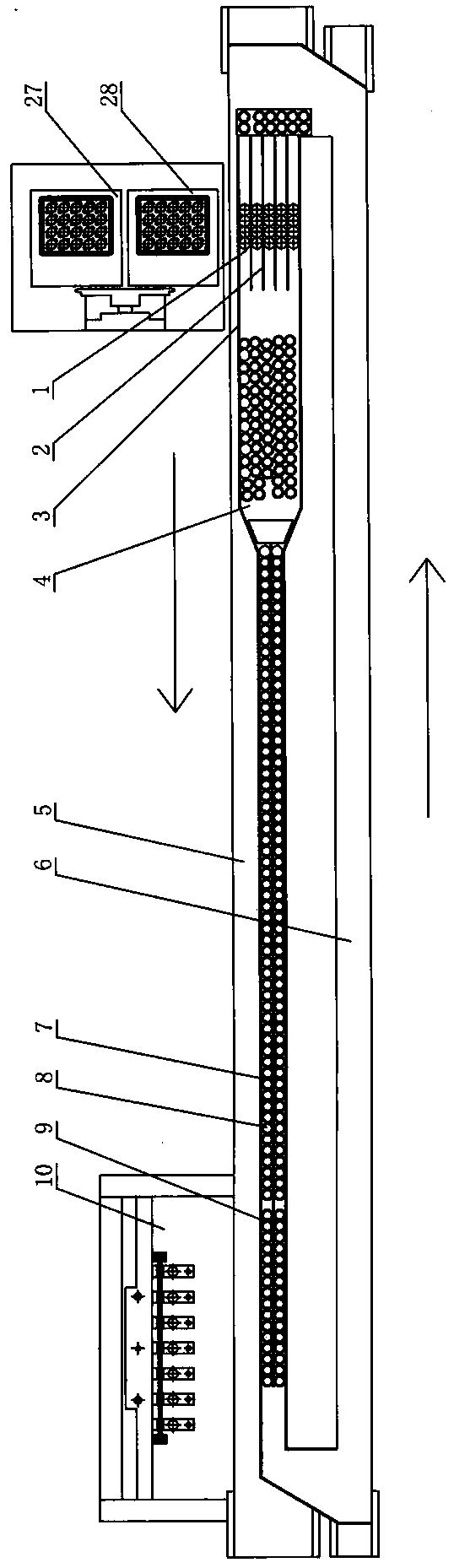

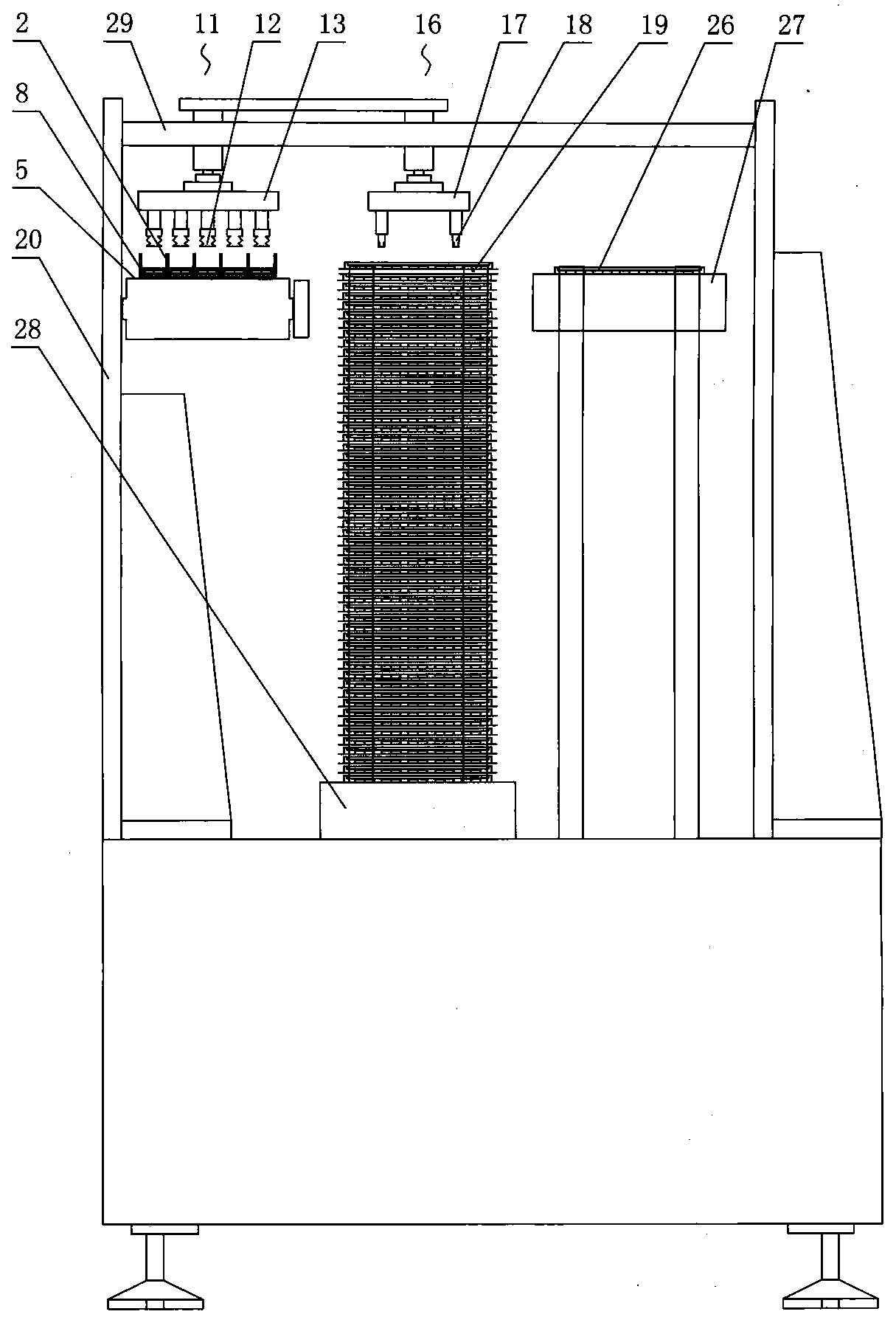

[0019] With reference to the accompanying drawings, the feeding mechanism of this button battery packaging machine includes a frame 20, and the frame is provided with a battery feeding device 11, a bulb recovery device 16, a battery feeding device 21, a battery conveyor belt 5 and a material Storage seat 28, the battery conveyor belt 5 is provided with a mold box 8 for placing batteries, that is, the battery 19 is transported on the battery conveyor belt 5 through the mold box 8; guide rail 2, and the periphery of the battery conveyor belt 5 is provided with a guide plate 3 for limiting and guiding the mold box; To the recycling area 6 of the feeding area, the conveying direction of the battery conveyor belt in the recycling area 6 is opposite to that of the battery conveyor belt in the feeding area 4; the material storage seat 28 is arranged on one side of the battery conveyor belt 5, and the battery feeding The device 11 and the battery feeding device 21 are respectively arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com