Naphthalene tail gas recycling system

A recovery system, a technology for naphthalene tail gas, applied in containers, packaging, transportation and packaging, etc., can solve the problem of lack of ready-made technology and equipment, and achieve the effect of ensuring occupational health and safety, saving energy, and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

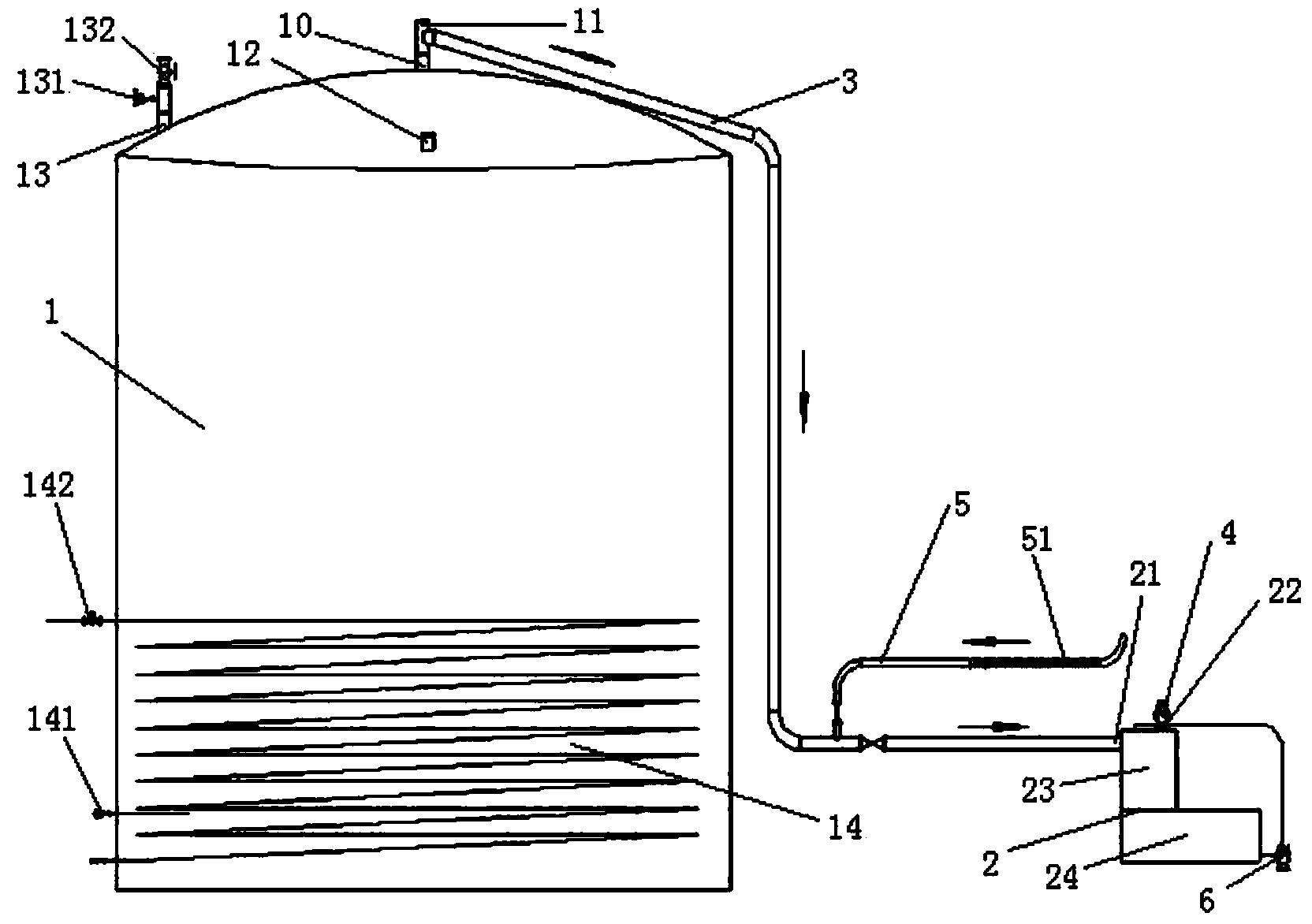

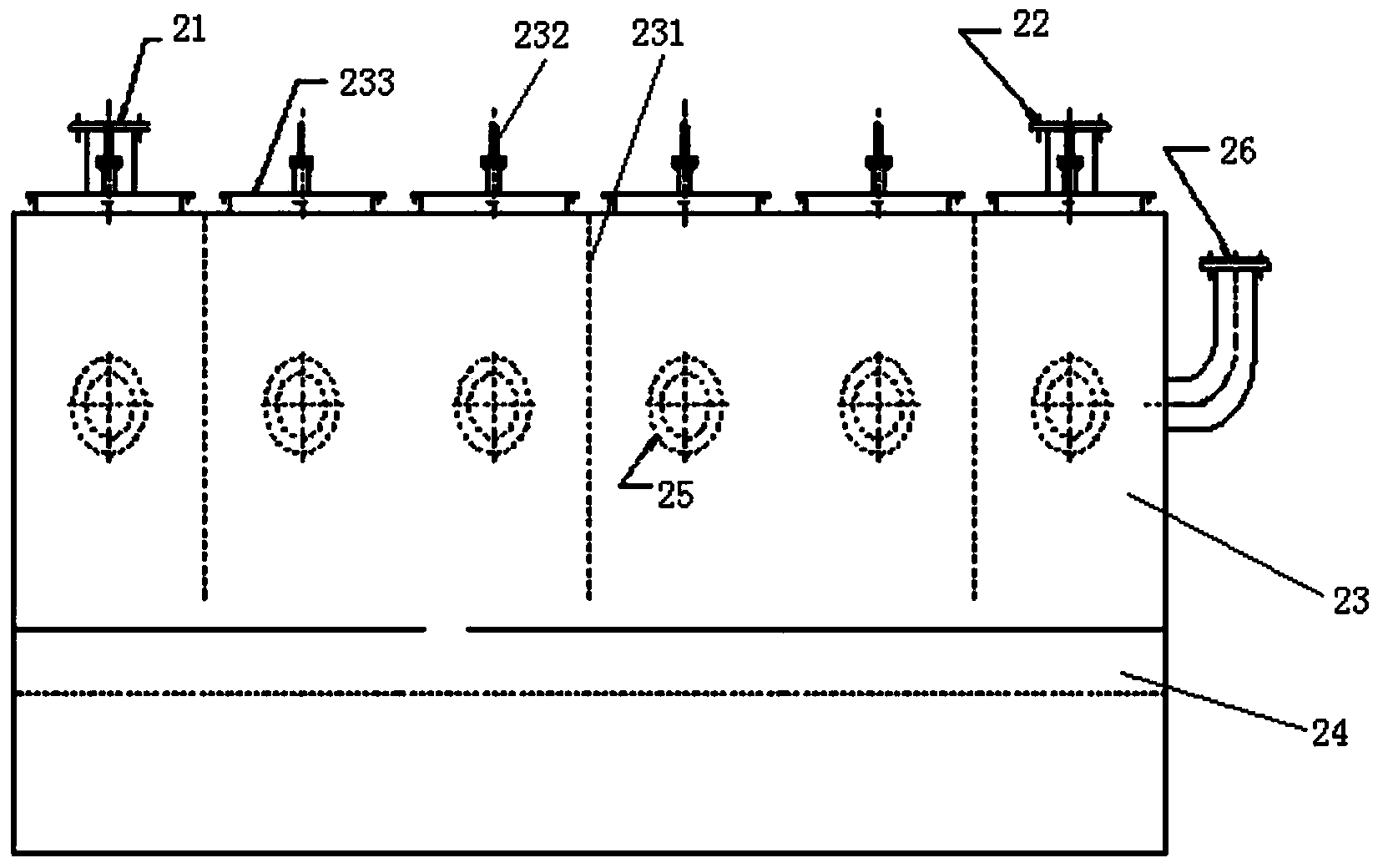

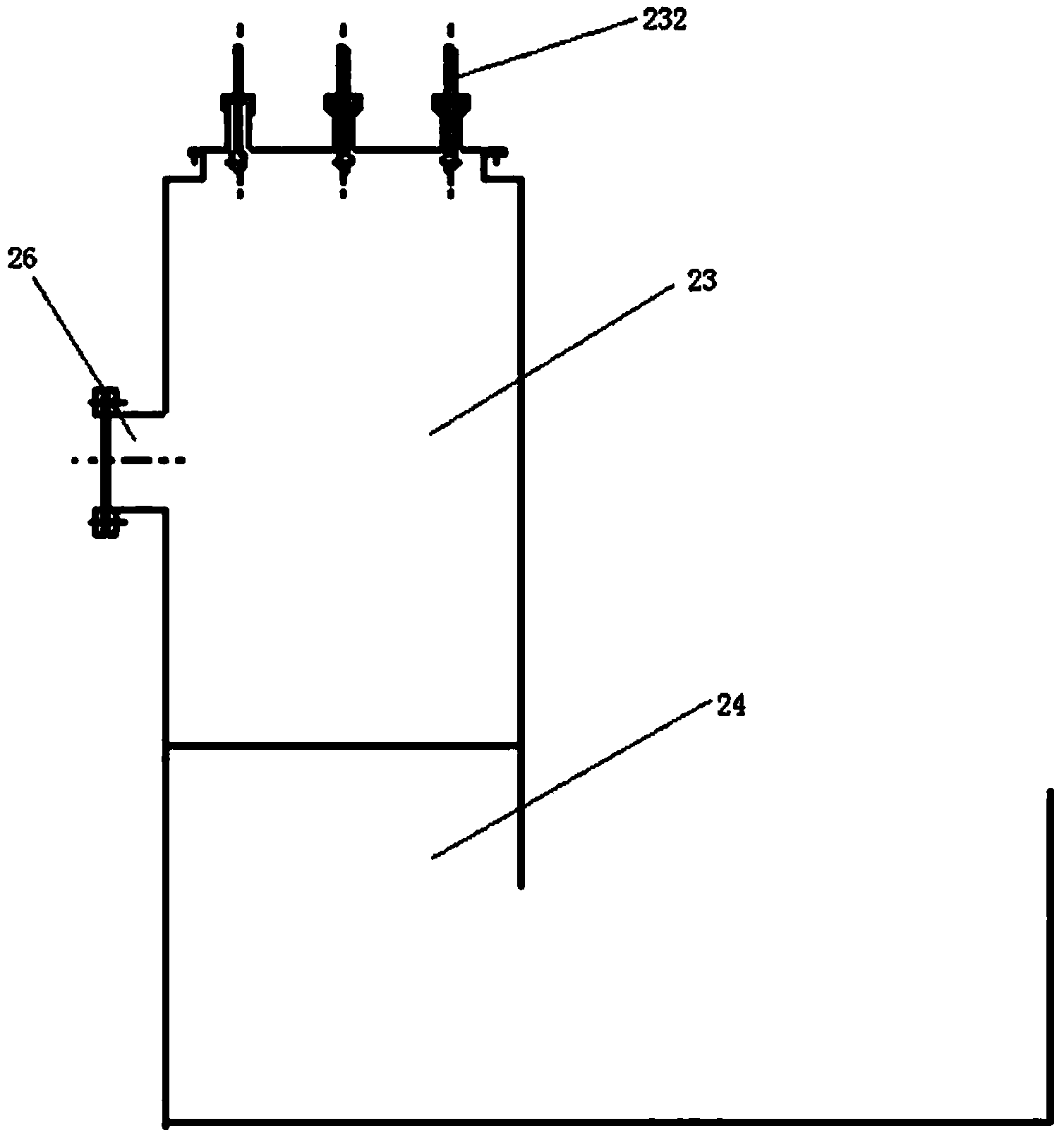

[0030] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0031] Such as figure 1 , figure 2 and image 3 Shown, a kind of naphthalene tail gas recovery system comprises a naphthalene tank body 1 and a naphthalene catcher 2, the top of the naphthalene tank body 1 is provided with a naphthalene ventilation hole 10, and the top of the naphthalene catcher 1 is provided with an inlet Air port 21 and air outlet 22, naphthalene air vent 10 are connected with air inlet 21 by pipeline 3, and a 500m3 / h induced draft fan 4 is installed at air outlet 22, and the storage tank tail gas discharged from naphthalene air vent 10 is drawn The fan 4 is introduced into the naphthalene trap 2 through the pipeline 3 for recovery; it also includes a pipeline 5 connected to the exhaust gas of the vehicle, and the pipeline 5 is connected to the pipeline 3, and a DN100 electric motor is installed near the pipeline 5 at one end of the veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com