A centralized oilfield fracturing wastewater treatment system

A technology for fracturing wastewater and treatment systems, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of failure to treat and reuse wastewater, and it is difficult to ensure full reuse , high cost and other issues, to achieve economical and practical clean production, improve recycling performance, and reduce input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

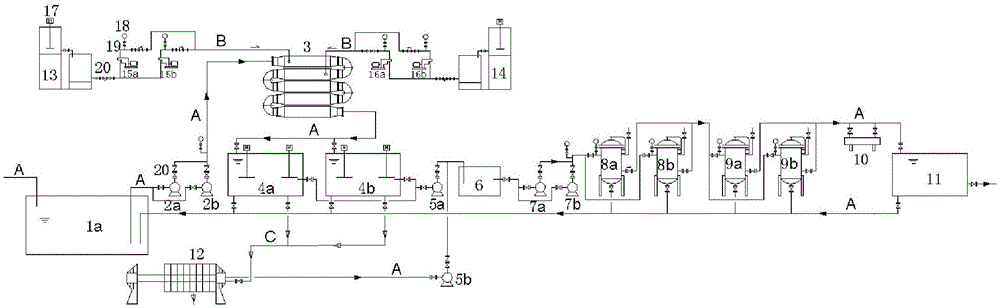

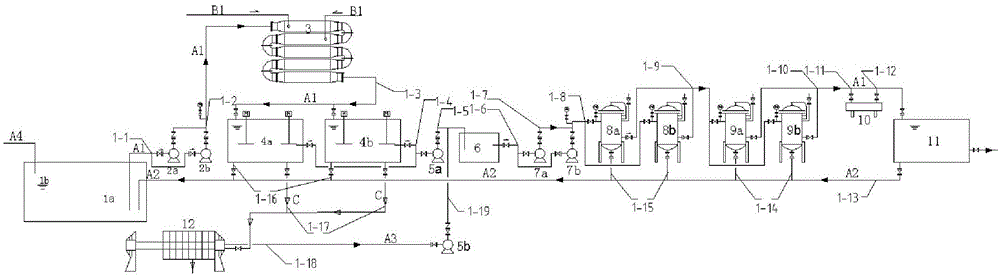

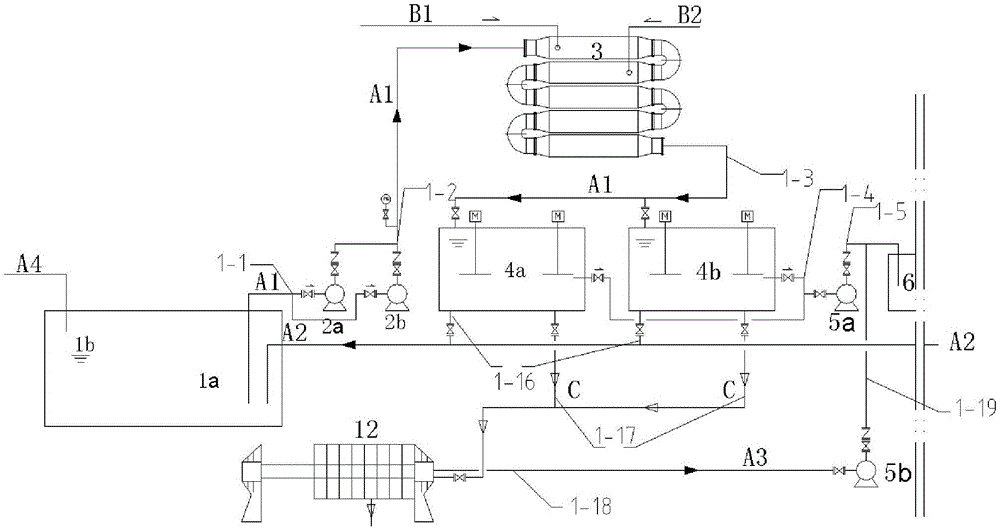

[0075] See figure 1 As shown, the embodiment of the present invention provides an oilfield centralized fracturing wastewater treatment system. The system at least includes: a water treatment system pipeline A, a pharmaceutical dosing system pipeline B, a mud discharge system pipeline C and related branch pipelines, and related equipment , Related valves, instruments, related circuits, etc.; the related equipment includes at least: fracturing flowback fluid storage tank 1a, sedimentation and degreasing device 1b, wastewater lift pumps 2a, 2b, pipeline mixer 3, coagulation sedimentation tank 4a , 4b, water transfer pumps 5a, 5b, intermediate water tank 6, filter pressurization pumps 7a, 7b, filter bag filters 8a, 8b, filter element filters 9a, 9b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com