Centralized treatment process of oil field fracturing wastewater

A technology for fracturing wastewater and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , the problem of high cost and high cost, to achieve the effect of cleaner production, economical practicability, improved regeneration and reuse performance, and reduced input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

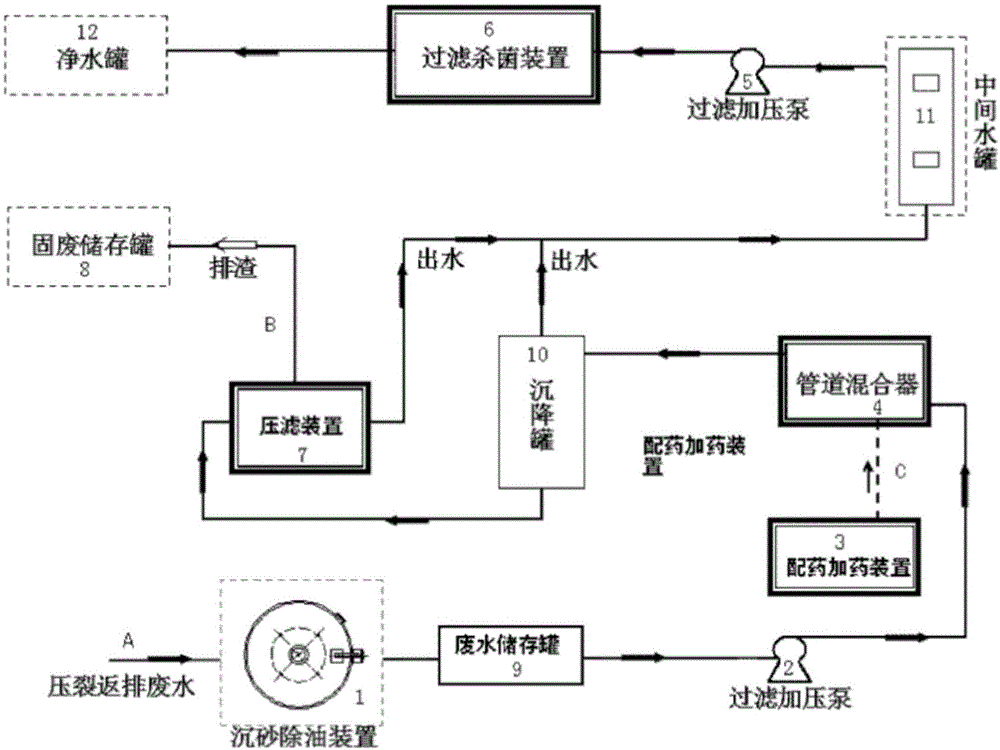

[0049] see figure 1As shown, the embodiment of the present invention provides a centralized oilfield fracturing wastewater treatment process, aiming at the water treatment needs of the oilfield site, and centrally solves the problem of fracturing wastewater treatment and reuse in the development block; the treatment process includes at least : Sand degreasing device 1, waste water lifting pump 2, drug dispensing and dosing device 3, pipeline mixer 4, filter booster pump 5, filter sterilization device 6, filter press device 7, solid waste storage tank 8 and other related equipment, and Including at least one waste water storage tank 9, settling tank 10, intermediate water tank 11, water purification tank 12 and other related facilities ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com