Process for efficiently enriching and recovering precious metals platinum and palladium by using solvent extraction method

一种贵金属、萃取法的技术,应用在溶剂萃取体系领域,能够解决影响贵金属萃取回收、回收过程复杂、易污染环境等问题,达到萃取富集效果好、工艺简单、操作过程简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] 1. Prepare working fluids with platinum and palladium concentrations of 25 mg / L each, and working fluids with nickel, copper, iron, aluminum, and manganese concentrations of 400 mg / L;

[0028] Stir magnetically in a constant temperature water bath at 35°C, dissolve 2-methoxyphenylthiourea with 2.5mol / L HCl solution, the mass fraction of 2-methoxyphenylthiourea is 0.05%, and obtain 0.05% 2-methoxyphenylthiourea phenylthiourea-hydrochloric acid solution;

[0029] 2. Preparation of aqueous phase stock solution:

[0030] In the experiment, 25ml of water phase was used for each group of extraction experiments, and one group was taken as an example to prepare as follows:

[0031] Take 1ml each of the prepared platinum, palladium, nickel, copper, iron, aluminum, and manganese working solutions with a pipette gun, and 10ml of 0.05% 2-methoxyphenylthiourea-hydrochloric acid solution, and adjust the acidity ([H + ]) is 3mol / L, obtain the aqueous phase stoste of volume 25ml, sha...

example 2

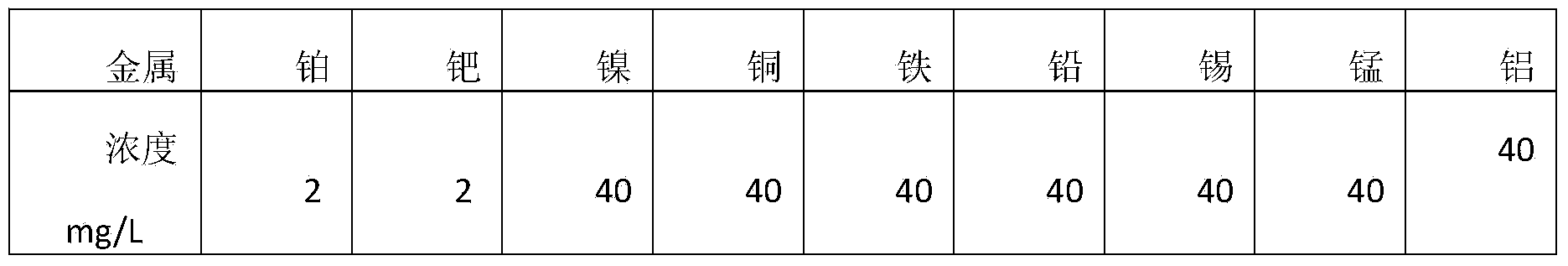

[0041] 1. Prepare working solutions with platinum and palladium concentrations of 50 mg / L each, and working solutions with nickel, copper, iron, tin, aluminum, manganese and lead concentrations of 1000 mg / L;

[0042] Stir magnetically in a constant temperature water bath at 40°C, dissolve 2-methoxyphenylthiourea with 6mol / L HCl solution, the mass fraction of 2-methoxyphenylthiourea is 0.2%, and obtain 0.2% 2-methoxy Phenylthiourea-hydrochloric acid solution;

[0043] 2. Preparation of aqueous phase stock solution:

[0044] In the experiment, 25ml of water phase was used for each group of extraction experiments, and one group was taken as an example to prepare as follows:

[0045] Use a pipette gun to take 1ml each of the prepared platinum, palladium, nickel, copper, iron, lead, aluminum, manganese, and tin working solutions, and 10ml of 0.2% 2-methoxyphenylthiourea-hydrochloric acid solution to adjust the acidity ([H + ]) is 4mol / L, obtain the aqueous phase stoste of volume...

example 3

[0055] 1. Prepare working solutions with platinum and palladium concentrations of 50 mg / L each, and working solutions with nickel, copper, iron, tin, aluminum, manganese and lead concentrations of 1000 mg / L;

[0056]Stir magnetically in a constant temperature water bath at 50°C, dissolve 2-methoxyphenylthiourea with 6mol / L HCl solution, the mass fraction of 2-methoxyphenylthiourea is 0.5%, and obtain 0.5% 2-methoxy Phenylthiourea-hydrochloric acid solution;

[0057] 2. Preparation of aqueous phase stock solution:

[0058] In the experiment, 25ml of water phase was used for each group of extraction experiments, and one group was taken as an example to prepare as follows:

[0059] Use a pipette gun to take 1ml each of the prepared platinum, palladium, nickel, copper, iron, lead, aluminum, tin, and manganese working solutions, and 10ml of 0.5% 2-methoxyphenylthiourea-hydrochloric acid solution to adjust the acidity ([H + ]) is 4mol / L, obtain the aqueous phase stoste of volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com