A kind of unbonded prestressed geogrid with anti-bending performance

A geogrid, non-bonded technology, applied in the field of reinforced materials, can solve the problems of increased contact area and increased friction, and achieve the effect of reducing friction and increasing bending deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation will be described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to this specific implementation.

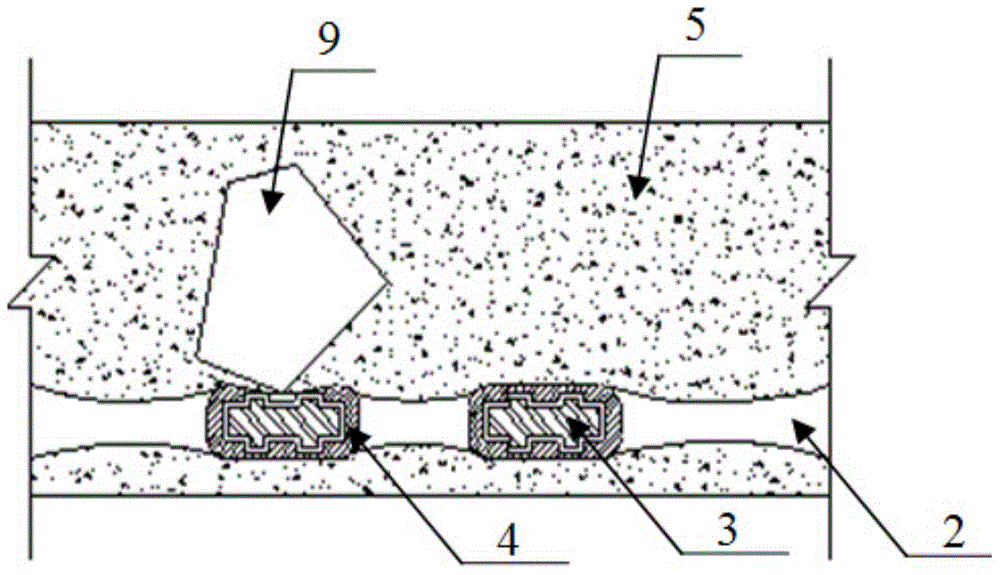

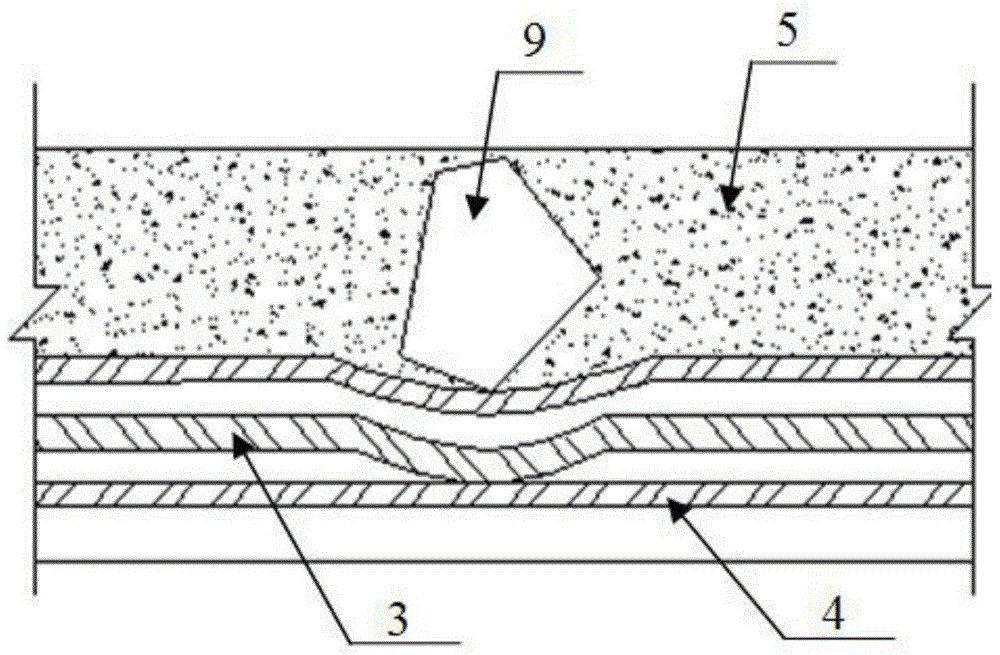

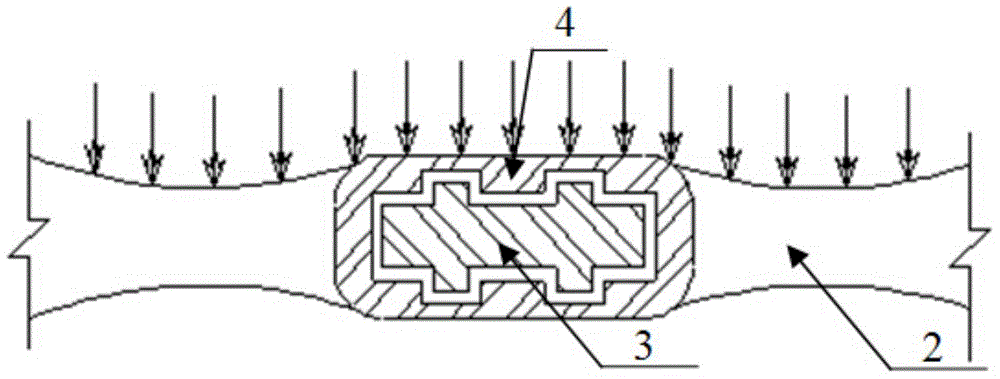

[0027] Figure 5-Figure 10 The unbonded prestressed geogrid of the present invention includes a main stress-bearing part 1 and a secondary stress-bearing part 2 . The main stress-receiving part 1 includes an inner reinforcement material 3 and an outer reinforcement material 4 , and graphite is filled between the outer reinforcement material 4 and the inner reinforcement material 3 . The secondary stress-bearing part 2 is in the form of a geogrid, which is the same material as the external reinforcement material 3 of the main stress-bearing part 1 .

[0028] The external reinforcement material 4 of the main force receiving part 1 is in the shape of a circular tube, which can effectively disperse the received force to the secondary force receiving part 2; the internal reinforcement ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com