Overall concrete stair mold

A technology of integral molding and concrete, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of difficult quality, heavy workload, repeated construction, etc., and achieve pouring and forming. Stable quality, good consistency, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

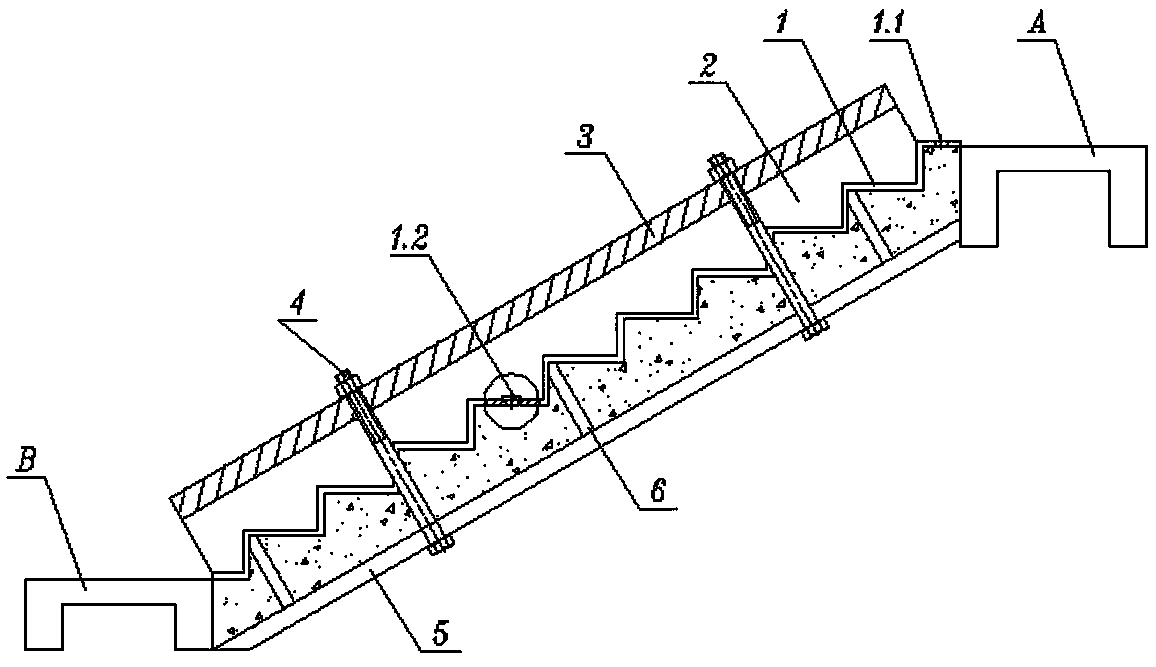

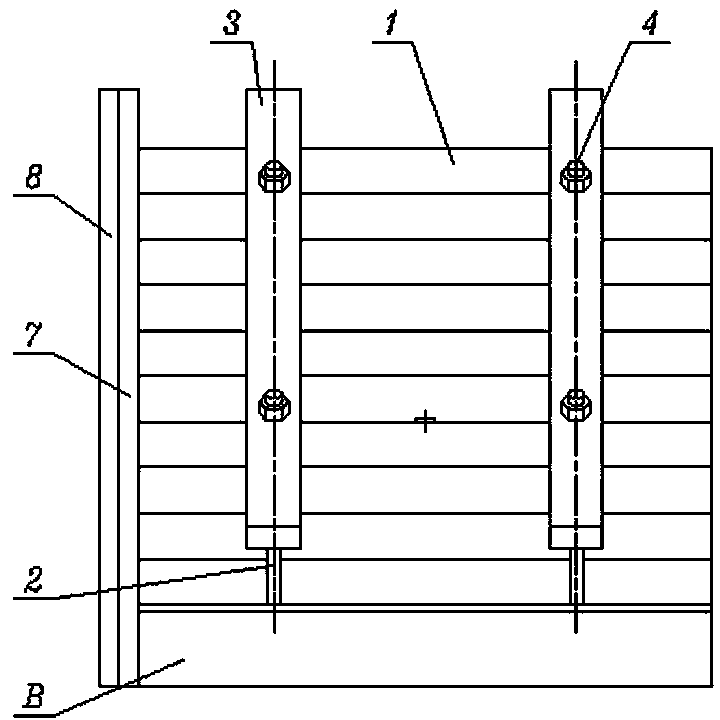

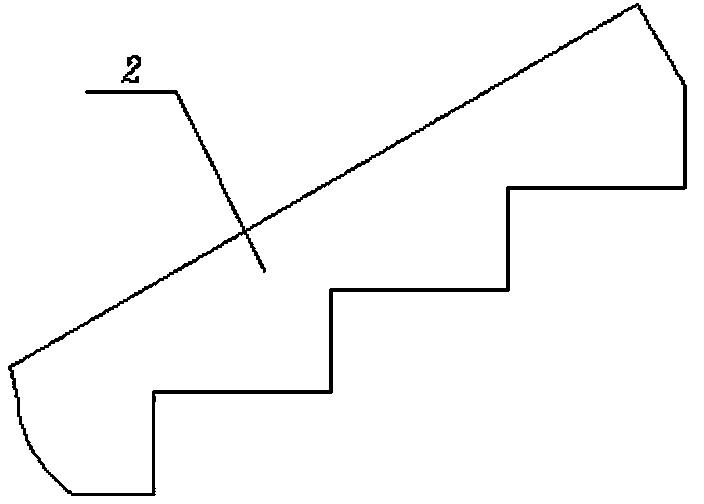

[0017] figure 1 The overall forming mold for concrete stairs shown is used for the construction of pedestrian stairs in a high-rise residential building. It includes upper formwork shell 1, tooth plate 2, pressure bar 3, bolt 4, bottom formwork 5, inner support 6, side plate 7 and guard plate 8. The upper mold shell 1 is the main part in the present invention. In the present embodiment, the upper mold shell 1 is made of a plastic plate, and the mold is a kind of oblique forming mold arranged in order by multiple steps of the same size. In order to reduce the sagging deformation of the upper mold shell 1, the inner support 6 perpendicular to the plane of the bottom mold 5 is arranged at intervals in the lower mold cavity of the upper mold shell 1. Because the present embodiment is a pedestrian staircase in a residential building, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com